A decade of success

Dudley-based GF Laser is celebrating 10 years as a leading supplier of subcontract flatbed 2D and 5-axis 3D laser cutting services.

The company, which has grown into a £2 million turnover, 20 employee business, started trading in 2006 with a newly acquired Trumpf TLC Cut 5, 5-axis laser, a machine that is still working reliably and proficiently to this day. In the intervening years, the company has invested in three further Trumpf laser cutting machines, which today form the bedrock of success at this progressive subcontract manufacturing business.

GF Laser was formed after being spun-out of sister company Moseley Brothers with the intention of creating a business based on 5-axis laser cutting. Today, however, the ISO 9001 accredited company also offers 2D laser cutting, formed tube cutting, sheetmetal bending, welding and powder coating services. Besides the provision of 24/7 production capacity, the company can also offer next day delivery to UK and Europe using its dedicated vehicles or retained couriers.

“We serve industries that range from automotive and yellow goods, through to construction and architectural,” explains director Simon Tregillus. “We’re one of only a few UK laser cutting companies to offer laser cutting utilising both 5-axis and 2-axis machines.”

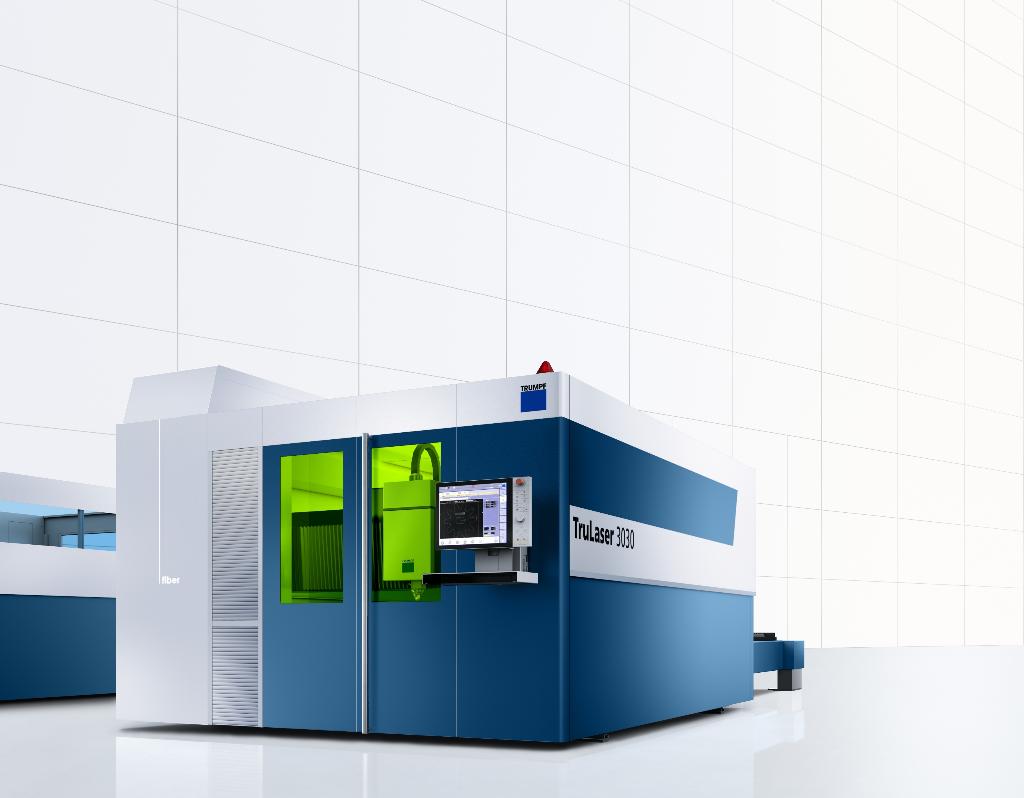

Aside from the original Trumpf TLC Cut 5, the company also has a Trumpf TruLaser Cell 7040 5-axis laser with the latest split cabin technology and a Trumpf TruLaser 3030 flatbed laser. The most recent installation however, is a Trumpf TruLaser 3040 Fiber, which with its large bed can cut components up to 4,000 by 2,000mm.

“The machines are extremely quick and reliably produce high quality parts, which is essentially why we keep returning to Trumpf for our new laser machine requirements,” says Mr Tregillus. “The TruLaser 3040 Fiber, which we installed in 2015, is so fast that we are on course to achieve our shortest ever ROI.”

The company’s commitment to ongoing investment is one of the principal reasons for its success, along with tight control over costs that can be passed on to customers, a dedicated in-house quality department and fast turnaround capability. The combination of these factors helped the company achieve its highest ever monthly turnover in March 2016.

GF Laser cuts parts up to 25mm thick in all materials, including copper and brass, while batch sizes range from 1-off prototypes up to high volume quantities.

GF Laser http://gflaser.co.uk

Trumpf www.uk.trumpf.com