Adding a new dimension

Waterjet cutting in two- and three-dimensions on one machine offers designers and production engineers important new opportunities to innovate and save costs.

This is the key message from ICEE Managed Services which specialises in the waterjet cutting process. The company also provides fibre laser cutting, bending or forming, fabrication and assembly services.

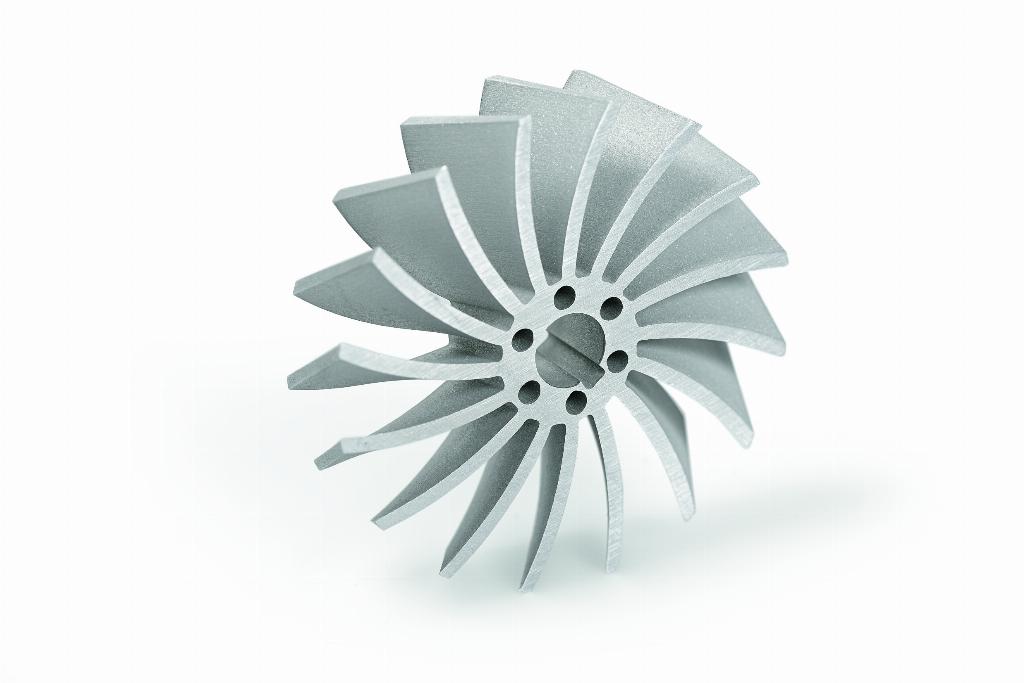

ICEE’s key account manager Shane Thomas says: “Until recently it has only been possible to cut two-dimensional profiles in a variety of materials by waterjet, but with the latest investment ICEE has made in new equipment with advanced 5-axis CNC technology, we can cut compound 3D forms as well, all on one machine.”

“Waterjet cutting in 2D and 3D opens up exciting new possibilities for designers to take a fresh look and be innovative in the use of materials and a process they might not have considered before, while production engineers may be able to have parts made now that could only be made previously by costly machining or casting.”

Mr Thomas says that in some cases, 2D and 3D waterjet cutting (where a high-pressure jet of water is mixed with abrasive particles and forced at around 60,000psi through a nozzle only 0.8mm in diameter) may be the only practical and affordable way to make parts.

The waterjet process, both 2D and 3D, will cut through a variety of different materials and thicknesses including metals, plastics, wood and stone, such as granite over 200mm thick.

Besides waterjet, fibre laser cutting and parts forming and bending operations, ICEE offers a comprehensive turnkey manufacturing service that includes welding, finishing, fabrication and assembly. With these facilities the company also makes bespoke equipment enclosure products for the telecommunications, broadcasting and data processing industries.

ICEE www.icee.co.uk