Bespoke air gauging for gear cases

Rotork, a leading actuator manufacturer and flow control company, works closely with companies in the oil and gas, water and waste water, power, marine, mining, food, pharmaceutical and chemical industries across the globe.

The company’s products and services are used throughout the world to improve process efficiency, assure safety and protect the environment. It supplies an extensive range of valve actuators, designed to withstand the challenges of harsh environments, including subsea and nuclear. It also provides a complete range of assembly and test services.

Within its range of actuators, the Bath headquartered company, produces a gear case made from aluminium alloy. Among other features to be inspected on the case are seven critical diameters, six parallel and one taper, ranging in diameter from 21mm to 184mm. The size and form of these features is important because when they are fitted with their mating part, a flameproof joint is formed.

Each of these diameters is required to be meticulously checked for roundness and diameter, with tolerances varying between 0.02mm and 0.05mm. The results from each measurement are then collated and recorded within Rotork’s Statistical Process Control (SPC) system.

Rotork had been using a contact gauging method of measurement for many years, however, due to the abrasive nature of the material and the tendency for aluminium alloy to ‘cold weld’ itself to any part that it comes into contact with, Rotork approached Bowers Group with a view to discuss the merits of changing over to a non-contact gauging method for these parts.

Air gauging is a measuring system that makes no physical contact with the component at the measurement point. Bowers has many years’ experience in producing air gauges, and in January 2015 it invited Rotork and its associates to a meeting at its Camberley demonstration centre to discuss the merits of moving to a non-contact air gauging solution.

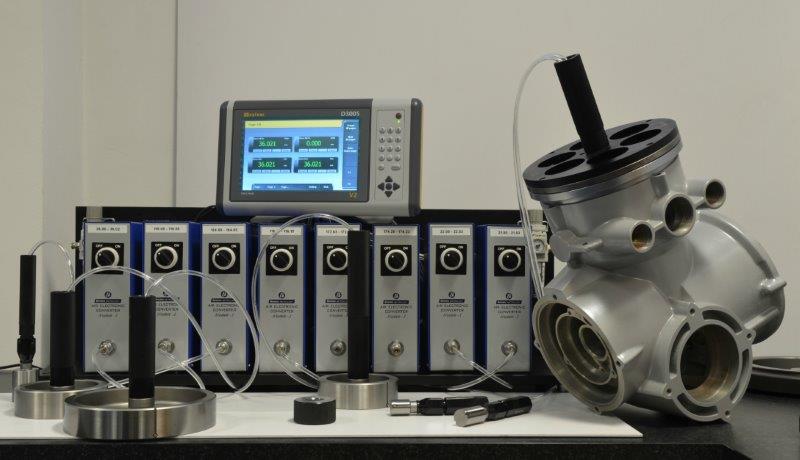

Rotork has made substantial investments over the years in the Sylvac D300s digital displays, and understandably wanted to retain this equipment as the preferred display for the measured results. At that time, Bowers did not have an air gauge system that could be used in conjunction with the D300s and so the process began to develop a bespoke solution.

In conjunction with a current air gauge supplier, Bowers put a proposal forward for an eight channel air gauging station that incorporated all of the requirements stipulated by Rotork. This system would be capable of linking in with the Sylvac D300s as requested. Early testing of the system showed the measuring results to be very stable; it also proved easy to calibrate and simple to use.

Based on these encouraging early results, the customer placed an order for two identical systems in July 2015 and the manufacturing process began. It was completed in late October 2015 and the first of the two systems were delivered to HPC (a key machining partner to Rotork) for testing on the Series two components.

Paul Dennett, a quality engineer at HPC comments: “The results are looking very good; even on the diameter 36mm bore which only has a 0.02mm tolerance. I must also say that the gauging is much more shopfloor friendly than the old contact style gauges.”

In December 2015, Rotork placed a further order for a 10 channel system based on the same principle which was completed in April this year.

Bowers Group www.bowersgroup.co.uk

Rotork www.rotork.com/en