Bespoke clamping and tooling brings productivity paybacks

The website of Brackley-based Luzzo Bespoke describes the company as ‘where aesthetics meets engineering’ and, with a customer base that includes luxury brands such as Roll-Royce Cars, Bentley, Bugatti, McLaren, Morgan and, Jaguar Land Rover in the automotive world, along with bespoke high-end furniture manufacturer Linley, it is easy to see how this description becomes reality.

The diversity of the products manufactured by Luzzo is wide, ranging from machining the minute hands for dashboard clocks, through complete jewel encrusted clocks, with one example containing £40,000 of gemstones alone.

With this type of work, much of what Luzzo produces begins life just as a concept, it then works with its clients to develop the idea and turn it into reality.

“Much of what we create are the fine finishing touches that mark one luxury product out from another for an individual customer,” says Alan Sawyer, sales and creative director at Luzzo Bespoke. “By its very nature this means we are not involved in big run production, with batch sizes varying from 5-off upwards. As the business has grown machining has become a big part of what we do and, over the past 10 years, the machine shop has developed from having no CNC machines to being virtually fully CNC, including 5-axis variants with multiple pallet loading capability.

“This gives us versatility as we can never be sure what is coming through the door next and it is normally needed on short notice. Therefore, flexibility of production is key. We must work smarter, be more efficient, and maximise the available machine capacity. Our palletised machines have the capability of running lights-out, so by investing time, and money, we can greatly improve efficiency and productivity.”

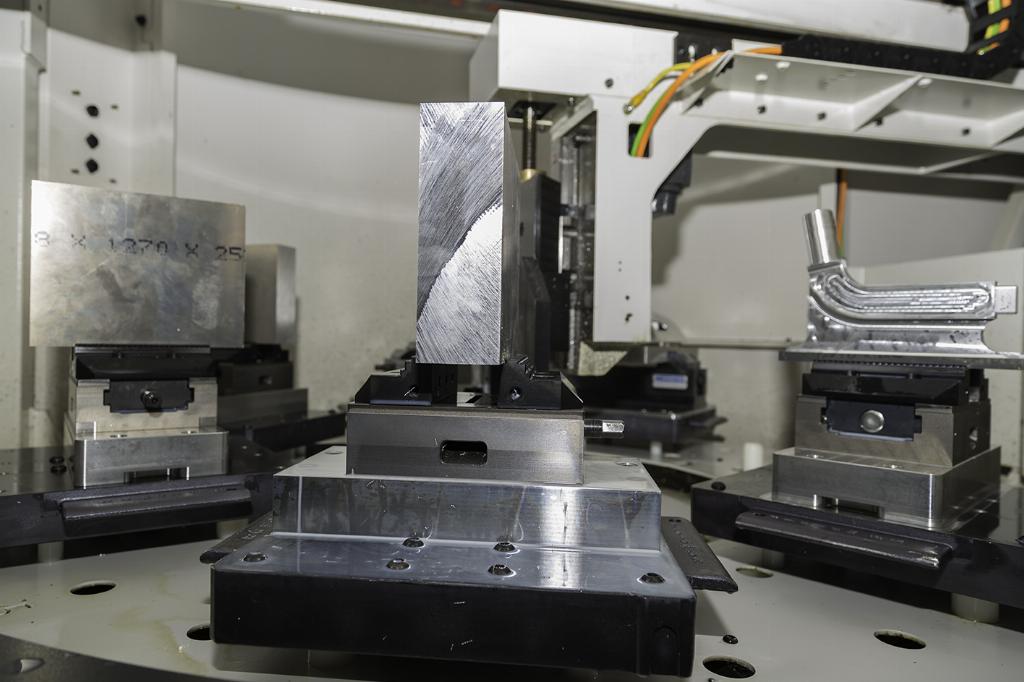

One of the first area that Luzzo looked at was workholding with the help of WNT UK’s technical sales engineer Warren Howard. The key area was maximising spindle run-time which would lead to lights-out machining, with the added bonus of reduced set-up times.

The solution from WNT was to use its ZSG4 centric vice system, which has high clamping forces and a large clamping range. Maximum gripping force is 35kN allowing maximum metal removal on components gripped on just 3mm of material. High accuracy, is ensured through the vice design, which features precision matched slides, resulting in repeatability of ±0.01mm as well as a totally enclosed clamping system that prevents any swarf ingress to the ballscrew spindle, making it easy to maintain and very reliable in operation.

Across its two palletised machines Luzzo is using 160mm and 300mm vices, capable of gripping billets up to 163mm and 303mm in width respectively. The company is also making use of WNT’s MNG Zeropoint baseplates that allows a combination of vices to be used to suit specific applications.

“A big advantage of the ZSG4 system is the fact that it is modular,” says Matt Garrett, 5-axis programmer at Luzzo Bespoke. “One of our pallet machines, a Mikron XSM 600 has a 42,000rpm spindle, but low torque, so it is ideal for high-speed finishing, whereas the other, a Mikron HEM 500U has a 20,000rpm high torque spindle, which we use for roughing.

“With the ZSG4 vices we can easily transfer parts from one machine to another, knowing that positional accuracy will be maintained. The ZSG system opens up many more possibilities to improve efficiency through different set-up solutions. Being confident that we can grip on just 3mm of material also means we can reduce material wastage without compromising on cutting data.”

With the initial issue of workholding settled, attention then turned to improving metalcutting performance. Again, working closely with WNT’s Warren Howard, the engineering team at Luzzo looked to maximise the benefits of its 5-axis capability and the Gibbs CAM software with its Volumill ultra-high-performance toolpath option.

“We recognised that there were some gains to be made so we had additional training on the software from Tech CADCAM and then called Warren back in to discuss tooling. His suggestion was to switch to WNT’s CCR-Al solid carbide cutters,” says Mr Garrett.

The Circularline CCR-AL are four-flute cutters capable of a high depth of cut and benefit from being used with the trochoidal milling strategy, which makes use of a continuous, high-speed toolpath to maximise metal removal and reduce cycle time.

The results of this switch have been significant savings, with one example of machining a part from 7-series aluminium, where 80% of the material is removed from a 200 x 160 x 50mm billet. The original cycle time was 90 minutes using conventional milling strategies, this was reduced to just 38 minutes through use of the CCR-Al cutters and trochoidal milling.

“The benefits we are seeing thanks to the combination of the WNT ZSG4 vices and CCR-Al cutters are brilliant,” says Mr Garrett. “This has been helped by the relationship we have developed over the years with WNT and Warren, who we know is always ready to offer advice and technical support if we need it.

“We will now expand our use of CCR cutters and trochoidal milling, using it not only on aluminium work, but also titanium and other materials. The cutters, in a variety of flute lengths and corner radii are now being added to our WNT vending machine.”

Ceratizit WNT www.wnt.com