Build quality wins the day

Focusing on the core competencies of turning milling and light assembly, KW Engineering (Poole) has built a highly successful subcontract business allied to the aerospace sector, gaining several accreditations along the way including AS9100 and customer approvals from heavyweights such as Airbus.

While that focus remains on aerospace, the group also has more down to earth ambitions, to produce the best fishing reels on the market under its Kingpin Reels brand.

At the heart of KW Engineering’s success is its willingness to invest in both capital equipment and systems which has allowed it to create an all-round service for its customers to include pre-production product development to enhance design for manufacture – shortly to include a 3D printing service.

However, metalcutting remains key to delivering parts on time and to the exacting quality demanded by the aerospace industry. Over the years Keith Ward, KW Engineering’s managing director has built up strong loyalties with machine suppliers, which is immediately evident by the colour schemes visible whilst walking around the machining areas.

That said, when the work demands it he is willing to consider alternatives, which was the case when he ordered a CMZ TA20YS-640 turning centre through independent machine tool specialist Ray Vockins who works on behalf of CMZ in the South of England.

“Myself and Ray had spoken many times about the CMZ range but at that time we were 100% committed to another manufacturer for our turning centres, so I kept turning him away,” Mr Ward reveals.

“That was until we won a three year contract for one specific component manufactured from stainless steel. We recognised that we would need a more substantial, rigid, machine with both a Y-axis and sub-spindle capability and the CMZ met that brief perfectly.”

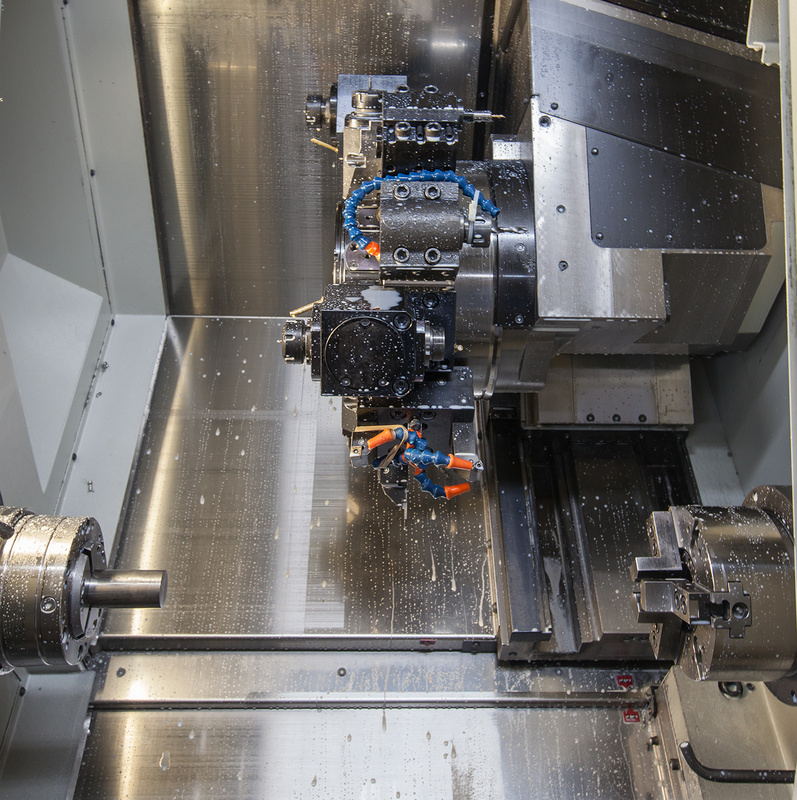

Before placing the order for the CMZ TA20YS-640, Mr Ward visited CMZ’s manufacturing facility in Spain with Mr Vockins and that trip convinced him that the decision he was making was the correct one: “I was very impressed with how CMZ built their machines and it helped to convince me that CMZ offered something different. Key to this was the use of traditional box slideways on all axes that help with the rigidity that we needed and the additional benefit that it helped improve tool life.”

The CMZ TA20YS-640 installed at KW Engineering features a main spindle with up to 22kW and 366Nm of torque available. The standard 640mm bed length can be extended with options of 400mm and 1,100mm and each position of the 12 station turret is capable of holding live tooling, driven by the in-built 12.000rpm, 75Nm/11kW motor.

The initial contract that justified the purchase of the CMZ machine may well be extended by the customer and with that taking approximately 60% of the available machine capacity, it is being kept busy with other work, including parts for the Kingpin Reels.

The reel manufacturing business came about after Keith Ward purchased the rights to the range when the original business ceased trading: “I saw it as a great opportunity to keep a British brand alive,” he says. “We have developed the range now and we are seeing significant business growth, particularly in export markets like the USA which completely buys into the Made in Britain element of the product. This is backed by the quality of the design and manufacture.

“KW Engineering is a great example of a successful UK subcontract company and its loyalty to one particular machine tool brand is not uncommon,” Ray Vockins explains. “But with the CMZ range we are winning over lots of business based on the quality of manufacture of the CMZ lathes and also the versatility of the range, which can include straightforward standalone 2-axis turning centres, through to twin turret, twin spindle gantry loaded cells.

“All of these benefits are centred around solid machine tool construction principles that provide a good base from which to produce high quality components.”

CMZ machines can be seen at MACH 2016 in hall 5 on stand 5230.

CMZ www.cmz.co.uk

KW Engineering www.kw-eng.co.uk