Software to simplify complex machining demands

After a decade of using Vericut machine simulation, verification and optimisation software, Advanced Manufacturing – Sheffield (AML) is extolling the virtues of providing industry-leading protection for its high-value capital assets and expensive parts. PES reports.

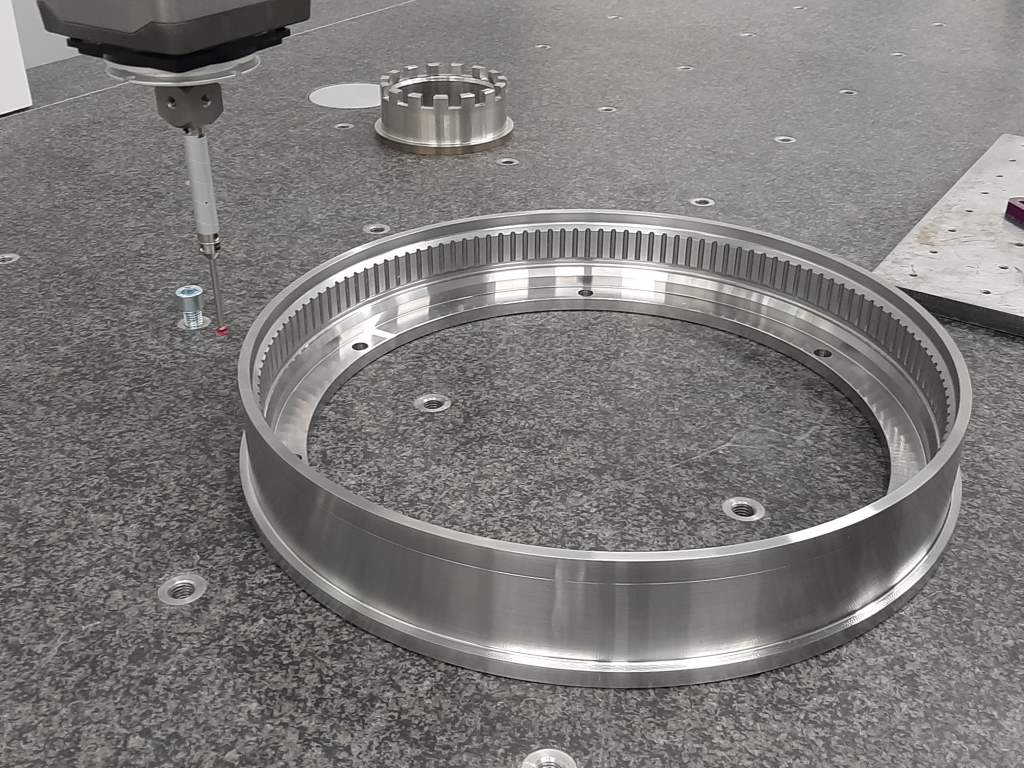

Originally a spin-out from the Advanced Manufacturing Research Centre (AMRC) AML is an advanced manufacturing supplier specialising in the development of manufacturing solutions, and production services for a number of prestigious blue-chip clients.

AML says that Vericut from CGTech is a key component of the business’ success at the rapidly expanding precision machining company, which serves a plethora of customers in sectors such as aerospace, energy and defence.

More recently, AML has embraced the efficiency and productivity gains offered by Vericut’s Force module, which is driving tool life gains and cycle time reductions in the order of 30-40%.

The company is AS9100 certified and carries a Rolls-Royce Certificate of Approval. In addition, AML is part of the ADS SC21 framework for 21st century supply chains to accelerate the competitiveness of aerospace and defence companies.

To manufacture the market’s highest quality precision parts, the company utilises the latest technologies, including Vericut simulation, verification and optimisation software.

“We’ve had Vericut from day one of manufacturing at AML, which dates back around a decade,” explains engineering manager Jason Mills. “It’s is our safety net; it looks after our complex components, some of which are machined from expensive forgings that cost in excess of £50,000 before we’ve even drilled a hole. There is no margin for error. We use all of the features in Vericut, including gouge detection, collision detection and, more recently, the Force module. The software also looks after our machine tools through virtual simulations, which are critical because a replacement spindle can cost around £40,000 for the hardware alone.”

Simulation steps

From receipt or generation of customer CAD, forging and stage models, AML engineers start building up what it calls the ‘Tech Pack’ from its Siemens NX CAM system, including documentation and any relevant paperwork. The company then starts importing the component, fixture and tool models into Vericut. Here, AML can take advantage of the software’s NX Interface, a function that provides an easy and convenient way to verify, optimise and analyse individual NC programs, a series of selected toolpaths or a complete sequence of operations, directly from within Siemens NX.

“We then start simulating the toolpaths, checking for everything that could possibly go wrong, from collisions and near misses, to spindles running in the wrong direction,” explains Mr Mills.

AML has seven seats of Vericut base and essential modules that include Verification (that detects program mistakes and verifies part accuracy), CNC Machine Simulation (which detects collisions and near misses between all components in the machining zone) and Multi-Axis (simulates multi-axis milling, turning and mill-turn operations).

The latter is vital as AML has 15 DMG Mori CNC machine tools on site, almost all of which are high-specification, multi-axis NT series mill-turn models. These include a large NT6600 with 6m bed and the latest arrival, an NT4250 DCG, which is capable of simultaneous 5-axis mill-turn operations with a direct-drive motor installed in the B-axis.

“Business is extremely busy, so we also have a DMG Mori DMU 125 FD 5-axis machining centre on order, and are looking at two more assets in the near future,” says Mr Mills.”

The company also takes advantage of further Vericut modules, including Auto-Diff, which compares a CAD design model with a Vericut simulation to automatically detect differences, weaknesses or mistakes in the design.

“We use Auto-Diff on every component as part of our standard operating procedure,” explains Mr Mills. “We find that it often flags up errors, especially as we have numerous mill-turn machines. The tools on mill-turn machines can be flipped round either way, so if they are not set-up correctly, Vericut will capture it.”

Additional simulation modules on site include CNC Machine Probing, which checks for probe collisions, and TDM Systems, which provides a live connection to tool data management (TDM). The company is now building tools in TDM for direct import into Vericut.

Using the force

Most recently, AML has added Force - Milling to its list of modules which makes optimising an NC program fast and easy by calculating the contact between the tool and material, cut-by-cut. Force also takes the cutting-tool edge and material into account, adjusting the feed rates accordingly so they are optimal and constant.

“We’ve seen up to 40% more tool life and 30-40% savings in machining cycle time when using Force,” explains Mr Mills. “The module is invaluable for our production work as it provides us with a competitive edge. It’s easy to use. We simply pick the material from the database and input the cutter geometry, which we get from the tooling manufacturer. Force then does its calculations in the background.”

AML has come a long way since spinning out of the AMRC (it remains a tier-two AMRC member to this day).

“We’ve gone from eight staff to 66; from two CNC machines to 15, and are imminently about to sanction another two,” explains operations director Mark Hands. “For the 2021-2024 period we set targets to grow turnover from £4.9 million to £12 million; headcount from 55 to 110; and assets (machine tools) from 10 to 22.”

AML is also working with a team of consultants from Sharing in Growth. The dedicated three-year transformation improvement programme involves the AML team committing to a comprehensive scheme of training, mentoring, coaching and development.

“We are big believers in reinvesting in our future, as well as our people,” says Mr Hands, who joined as a project engineer in 2011 and is now a company director and major shareholder.

Best practice

The company’s mantra is to apply the best manufacturing technology available to provide low-cost parts to customers. This is more than just a slogan; AML was born out of advanced research activities and the company still believes that technology is a key differentiator in providing value for customers and key to this goal is Vericut.

“Vericut brings security to our business,” says Mr Hands. “Not just because our parts are expensive, but because some are one-offs with no margin for error. We also rely on it to protect our CNC machines; large, expensive assets that are costly to repair. Right first time within the business is a must and Vericut is a vital part of that.”

Jason Mills concludes: “We’re comfortable and happy with the software, as well as the level of support we receive from CGTech. Today we apply Vericut to all of our parts. No matter what we change in NX, even if we just add a command to turn on the coolant, it goes through Vericut as it provides confidence for everyone in the business. You just can’t put a value on that.”

CGTech

www.cgtech.co.uk

AML Sheffield

www.amlsheffield.co.uk