Shining a light on machining without a guide bush

Birmingham-based brass lampholder manufacturer S Lilley & Son has found the ability to remove the guide bush when machining on its latest Citizen sliding head lathes has made them the natural successor to its ageing single-spindle cam auto machines. PES reports.

Now in its sixth generation of family ownership, S Lilley & Son has nearly finished phasing out the 20 or so cam-type, single-spindle bar autos it has used in its factory since the 1950s. In their place are 11 CNC, twin-spindle, bar-fed lathes up to 65mm capacity with driven tooling, six of them supplied by Citizen Machinery UK.

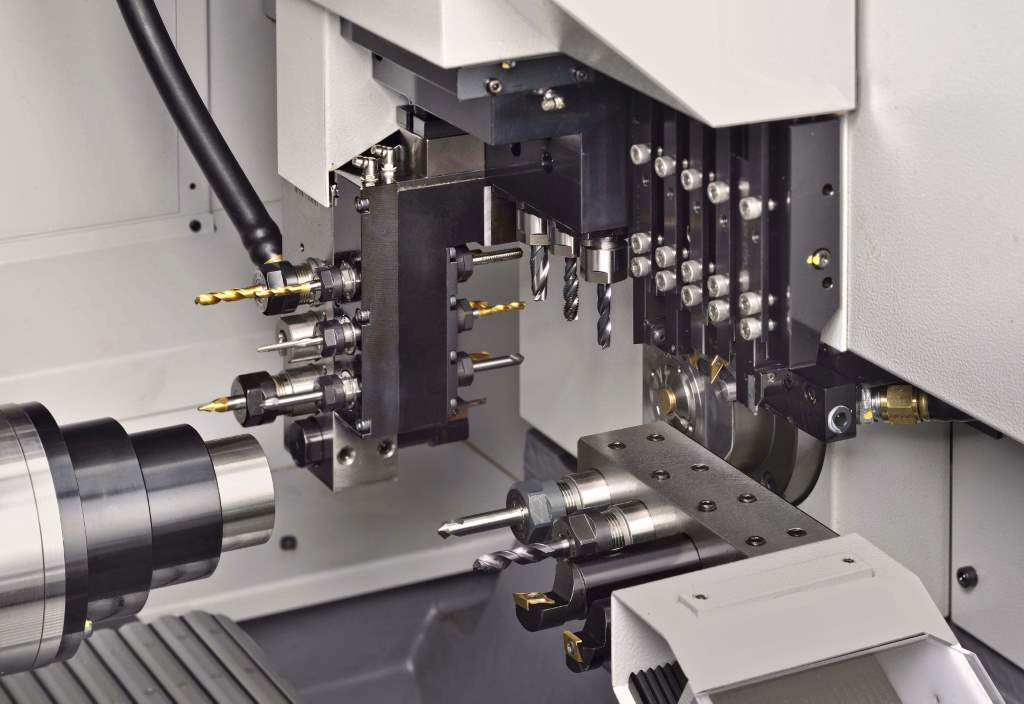

Two are Miyano BNA42-MSY fixed-head turning centres of 42mm capacity while the other four are Cincom sliding-head (sliders) models; two for turning, milling and drilling 32mm bar and two for processing 20mm stock. To achieve the high speed of production for which the outdated cam technology is renowned and couple it with the advantages of CNC operation, namely unattended running and rapid changeover for smaller economical batch sizes, the company operates the sliders almost exclusively without the guide bush in place.

S Lilley & Son is able to do this as most components for the light fittings it makes are shorter than 3.5xD. Normally a ratio of 2.5xD is approximately the limit when stock is not supported in a bushing otherwise the protruding length of bar deflects under pressure from the tool, causing inaccuracies during machining. However, the relatively open tolerances of the lampholder parts produced in Birmingham allow the company to push the limit higher, lowering the cost of manufacturing parts up to 40% longer by taking advantage of higher speed production without the guide bush.

Guide bush-less advantages

The rationale for investing in sliding-head lathes and choosing to operate them without the guide bush, rather than buying a fixed-head lathe, is due to the sheer speed of production that is possible using the in-line ganged cutters typically found in a sliding-head machine. It allows the linear cross slide to effect very fast tool changes between cuts. Cycles times are considerably shorter and sometimes even halved compared with using a fixed-head turning centre.

Guide bush-less operation on a sliding head lathe brings other advantages in addition to productivity benefits. Bar of lower dimensional quality and price can be tolerated, as there is no bush for it to seize in. The remnant after the last part has been machined from a bar is around one-third the length left after true sliding-head turning, so there is less material wastage. Notable also is that bar such as hexagonal or extruded, may be machined if the guide bush is not present.

Indeed, if support is not necessary for the stability of a part during machining, it is better to remove the guide bush as it can actually compromise accuracy. Holding roundness then becomes easier on short components, as the ability to achieve tolerance is dictated by the high-quality spindle rather than the bushing. Furthermore, it is possible to run at higher rotational speeds to achieve better production rates and surface finishes.

Transition from cams to CNC

S Lilley & Son’s transition from cam-type to CNC lathes started in 2008, later than in many companies for three reasons. First, as tolerances on its electrical products are not particularly tight, their production is relatively unaffected by the age of a machine tool; second, the fittings are frequently needed in large volumes commensurate with single-spindle cam auto operation; and third, the company was fortunate to employ a highly skilled cam auto setter-operator who retired in 2019. That was when the penultimate cam-controlled machine was sold, the single remaining auto being devoted to a particular long-running job.

The employee's departure was the trigger for the Lilley family to accelerate the purchase of Cincom sliders. A pair of 20mm capacity A20-VII models was installed, one in 2019 and another in 2020, as direct, more productive replacements for the former single-spindle cam autos.

The new sliders joined an L32 Cincom model installed in 2012 for producing parts up to 32mm diameter. This machine was swapped in 2017 for a more modern L32-XII. Likewise, this slider is only occasionally used with the guide bush fitted for producing some longer components from bar or tube.

Director Simon Lilley is of the opinion that, even though cam-type lathes can produce more components per hour than their CNC counterparts, the ability to set the latter machines much more quickly and run them unattended means that one Cincom is able to do the work of three of the older single-spindle cam autos.

Chip breaking software raises efficiency

In January 2022 a fourth Cincom arrived, an L32-XIILFV, with Citizen's low frequency vibration (LFV) chip breaking technology. The three existing sliders plus the Miyanos and other fixed-head lathes were approaching full capacity, so the new machine provided flexibility to swap work around the shopfloor and use it as a back-up for the remaining, ageing single-spindle cam auto.

As with the other sliders on site, the machine is rarely used with the guide bush fitted. So unwavering is the company’s policy in this regard that longer parts up to 5xD, which could be regarded as being best produced by sliding-head turning, are instead machined half way in the main spindle and transferred to the sub spindle for the remainder of the turning and milling to be completed. It saves half an hour's work installing the guide bush and another half hour removing it.

More than 95% of the firm's turned parts are made from free-machining brass bar, but lately there has been an increase in demand from customers for aluminium parts up to 32mm diameter and for plastic components such as acrylic LED lenses and acetal grommets.

Craig Lilley, another director and family member comments: "Anodising quality 2011 T3 aluminium is not as free-machining as it is made out to be and the 6026 T9 grade we turn is even worse in terms of its tendency to generate stringy swarf. Most plastics are similarly problematic.

"LFV fragments the swarf into manageable chip sizes so there is no longer a need to stop the machine to clear swarf tangled around the tool and component, so output is maintained.

"It is turned off automatically when it is not needed for chip breaking, so the slight reduction in material removal rate during LFV machining is minimised. It really couldn’t be more flexible."

Citizen Machinery UK

www.citizenmachinery.co.uk

S Lilley & Son

www.s-lilley.co.uk