Control and measurement technology at EMO Hannover

To manufacture products that satisfy the highest demands for accuracy and quality in a reliable, economic and efficient manner, having command of complex milling and turning processes is a competitive advantage.

German company Heidenhain believes that machine tools equipped with its controls, encoders and drive technology provide the best technical prerequisites, as will be presented during live demonstrations at EMO Hannover 2019 taking place from 16-21 September 2019.

Starting with a batch size of one, TNC controls provide process reliability, accuracy and productivity as well as facilitating simple, reliable digital integration of the machine into the process chain. Ensuring this are various functions including Dynamic Precision, Dynamic Efficiency and Connected Machining as well as numerous additional options.

Due to its split screen, the new TNC 640 with 24-inch widescreen and Extended Workspace Compact offers two work areas, allowing a user to have other applications displayed alongside the screen to create a user-friendly workstation for organising jobs digitally directly at the control.

Heidenhain will also present the new Component Monitoring option for TNC controls, which observes processes and protects machines from equipment failure due to wear or overload.

Elsewhere, during live demonstrations in the 'mav industrie 4.0 area', Heidenhain, OPS-Ingersoll and Haimer will show that intelligent data management of an automated manufacturing environment, including predictive job planning, works reliably and efficiently. The TNC 640 control with Batch Process Manager and StateMonitor software from Heidenhain enables well organised, fully digital processes.

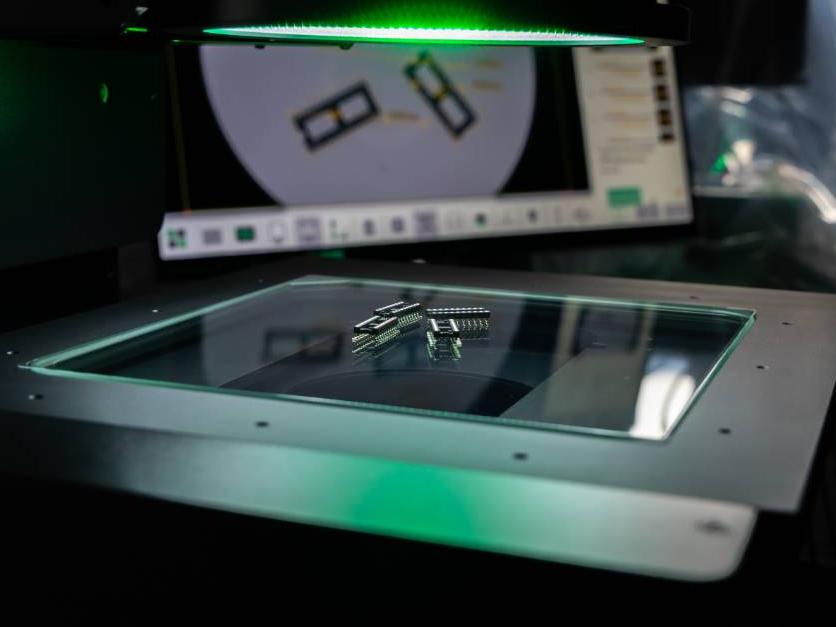

Heidenhain encoders for determining the position of linear and rotary axes are the industrial standard for closed-loop control, especially for dimensionally accurate production of contours that are not affected by thermally induced changes in the feed mechanism. At EMO 2019, the company will focus on angle encoders and together with Austrian group member AMO will present solutions for every rotary axis.

The RCN 2001 optical angle encoders with integral bearing and integrated stator coupling have been fundamentally redesigned. System accuracy is now even better and maximum speed is higher. Enhanced capabilities for monitoring the temperature increase process reliability.

The new generation of modular, optical ERA angle encoders is now equipped with the Heidenhain HSP 1.0 signal processing ASIC (application-specific integrated circuit). Until now, the HSP 1.0 has been used only in exposed linear encoders. It almost entirely compensates for fluctuations in signal amplitude caused by interference.

AMO will also present its WMKA modular, scale-tape solution for especially large diameters. These encoders feature EnDat and DRIVE CLiQ interfaces and are suited to safety-related applications.

Heidenhain touch probes and numerous probing cycles in the company's control systems increase the dimensional accuracy of finished workpieces. Set-up and measurement of workpieces and tools as well as calibration of machine kinematics are performed quickly and easily before machining or during production.

The touch probes are optimally tuned to the TNC cycles. Moreover, the wear-free sensor technology of the touch probes, flushers/blowers for cleaning the stylus, battery monitoring and effective collision protection ensure that results are measured with high process reliability.

Motors and control technology from ETEL and Heidenhain significantly contribute to dynamic, accurate motion control of machine tools.

The new GEN 3 generation of drives from Heidenhain, which will debut at EMO 2019, ensures maximum performance and offers intelligent transmission technology, powerful diagnostics and simple mounting and connection.

ETEL will present its TMB and TMK series of torque motors, which are high-torque systems for machine tools. Their particular strengths are a cogging-free design, optimum speed stability and exceptionally high control quality.

Once again a meeting point for experts, the Heidenhain TNC Club stand is open to all TNC users. The focus is on the advanced training of experienced specialists as well as on apprentice training of qualified junior employees. TNC Club will present a new training program for career progression: a training program to become a TNC specialist. In this way, Heidenhain supports premium members of the TNC Club in coping with the shortage of skilled staff.

Heidenhain (GB) www.heidenhaingb.com

Controls and encoders: Hall 9, stand I32

TNC Club: Hall 9, stand K32

Live demonstration of ‘Intelligent data management in automated manufacturing’ with OPS-Ingersoll and Haimer: Hall 9, industrie 4.0 area

Young Talent Foundation for Mechanical Engineering for advanced and apprentice-level skills training: Hall 25