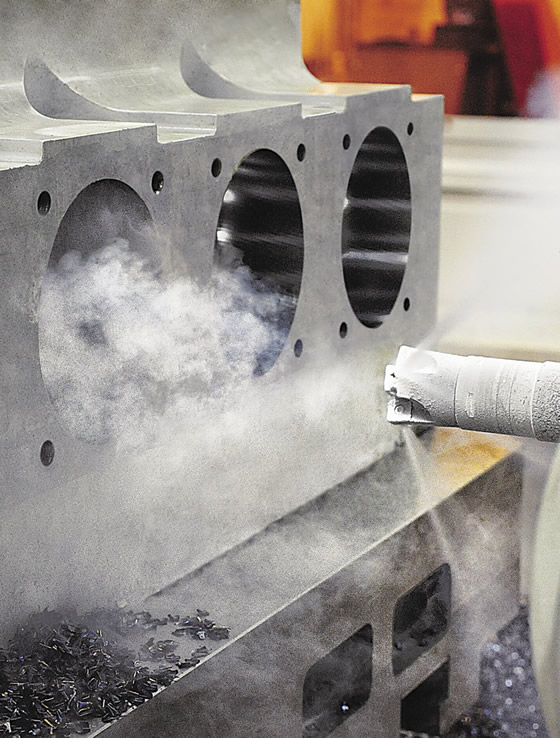

Cryogenic machining in action

Okuma and 5ME are joining forces to educate the machining world on the benefits of using internal liquid nitrogen (LN2) instead of coolant during the cutting process.

Okuma and 5ME are joining forces to educate the machining world on the benefits of using internal liquid nitrogen instead of coolant during the cutting process.

Currently, there are 12 Okuma machine models that can be ordered with 5ME cryogenic machining technology, including vertical machining centres and horizontal machining centres specifically designed for aerospace parts processing. In some instances cryogenic machining is retrofittable.

Cryogenic machining is a metal-cutting technology that increases throughput, quality and tool life while reducing cycle times. It is especially profitable when processing exotic metals commonly used in aerospace part production, such as titanium and Inconel.

This technology is fairly new to machining and many questions arise when people first consider using cryogenics. Here are a few little known facts about the technology:

- Chips are much easier to manage without coolant making them sticky and weighing them down. They are dry and lighter making them extremely portable. Additionally, the risk of slips and falls when clearing chips is reduced since there is no oily residue from coolant.

- Cryogenic machining equipment does not have to be permanent on the machine. Hardware can be removed from the machine to run through-spindle coolant instead of liquid nitrogen.

- Liquid nitrogen is quite easy to handle but there is a cold factor involved so safety measures, such as wearing gloves and aprons, should be implemented when handling tools.

- Liquid nitrogen is affordable, competitively priced and readily available from commercial distributors. The typical return on investment on a cryogenic machining kit is 12 months.

The video with this article shows cryogenics in action on an Okuma MA-600HII.

The authorised distributor of Okuma machine tools in the UK is NCMT.

Aerospace manufacturers can visit Okuma at the Farnborough International Airshow on 11th July - 17th July 2016 in Hall 3/D100 to discuss details.

Okuma www.okuma.eu

NCMT www.ncmt.co.uk