DECEMBER COVER STORY: Designing the new world

The world of product and component design has been transformed over the last thirty years by the introduction of CAD software such as SolidWorks. Ed Hill discovers what its developer Dassault Systèmes has in store for the future of design.

Over the years Dassault Systèmes’ SolidWorks design software has become a widely-used CAD/CAE option within the field of manufacturing, so the launch the latest version is always noteworthy.

SolidWorks is estimated to be used by more than 3.1 million users globally. The 2017 release features more power and performance, as well as new capabilities to address paperless manufacturing through the support of Model Based Definition, and printed circuit board (PCB) design.

Both new and experienced users are able to improve productivity with simulation to analyse, solve, visualise and verify functionality of designs, before any prototype is created.

The developers say the new tools unlock any 3D model for better collaboration with manufacturers and customers, and dynamic product data management (PDM) from concept through to manufacturing allows for stronger support of multi-site and remote teams.

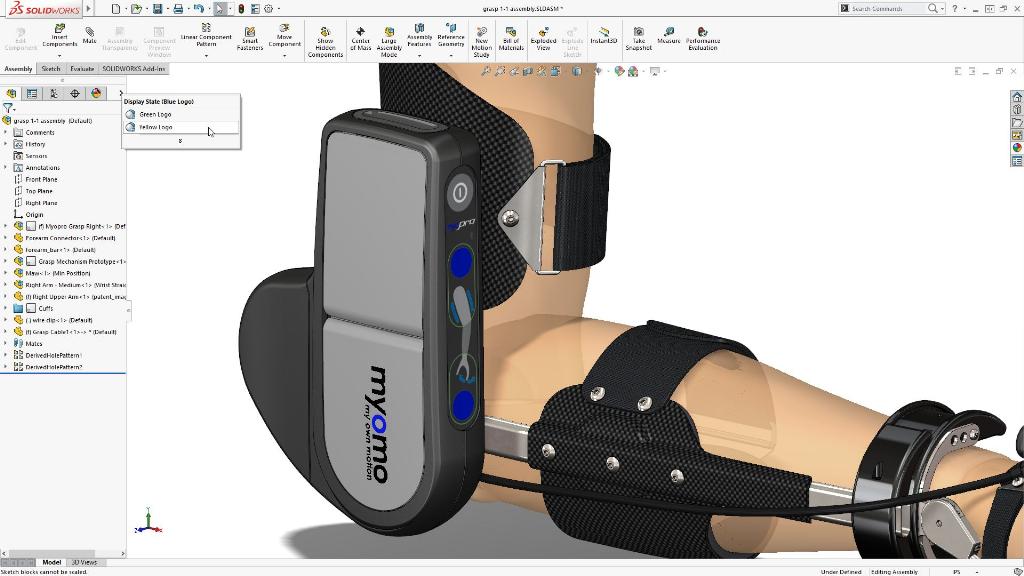

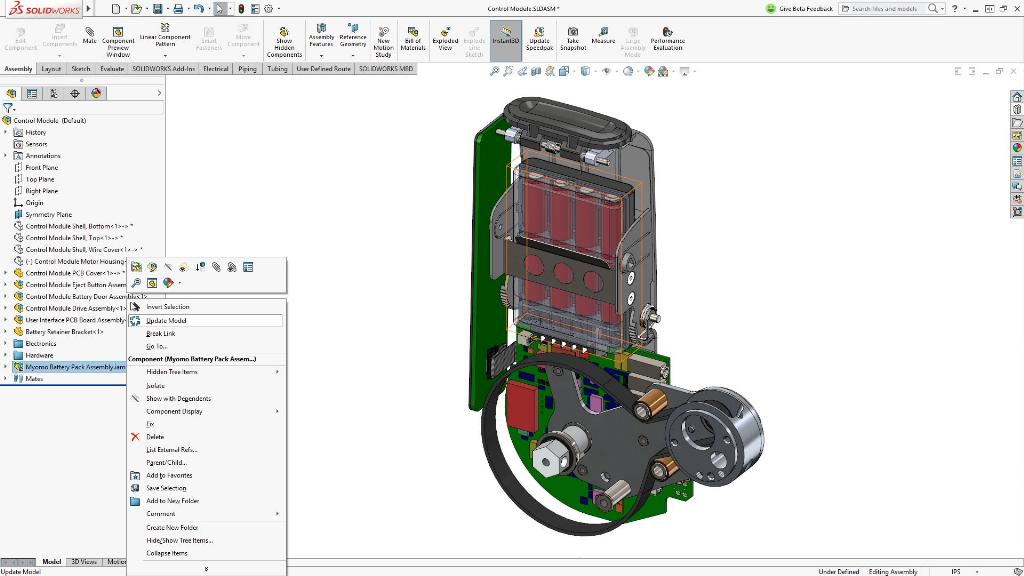

Andrew Harlan, principal mechanical engineer at Myomo, which produces electronic arm braces to help users with weakened limbs, says: “We must fulfil a lot of medical device requirements, and SolidWorks has been helpful for leveraging cutting-edge industrial design to get our work done faster for our myoelectric upper limb orthosis to market.

“We use SolidWorks exclusively for the full spectrum of our design work – the ability to collaborate with industrial designers, consultants and manufacturers across different time zones simplifies the whole process. The SolidWorks models are so accurate and appealing that we can quickly design, iterate and improve a highly technical part.”

Other features to accelerate the design process include more modelling power with new tools for chamfer, fillet, and advanced hole specification that create multiple variable chamfers in one simple operation.

With surfacing it is possible to remove obstacles to creating complex 3D geometry with new surfacing features such as wrap, drag and drop, emboss, deboss, and 3D Curve.

Dealing with data

There are many other improvements to the 2017 edition but perhaps some of the biggest developments come in the form of SolidWorks PDM which improves the way teams manage and collaborate on design by controlling design data and ensuring access to the right version of a design and SolidWorks MBD (model based definition). This advance auto-generates 3D PDFs, lists native CAD files in the SolidWorks PDM Vault structure, and keeps track of where they are used and overwrites versions to minimise clutter.

Gian Paolo Bassi, CEO, SolidWorks, Dassault Systèmes explains: “SolidWorks 2017 simplifies the design and development process with a better user experience, new capabilities for emerging technologies, and improved functionality for seamless collaboration with teams and networks.

“Each year, our SolidWorks community’s feedback drives our research and development to offer a flexible product portfolio for business, design and engineering needs. We are excited to put even more power and performance in their hands.”

Experience is the key

SolidWorks 2017 is part of what Dassault calls its 3DExperience platform. The European software developer launched the new platform in 2012 to bring all the groups of its software capabilities under one umbrella. As well as SolidWorks the 3DExperience platform also includes Dassault Systèmes’ original Catia design modelling simulation software and applications such as collaborative innovation software, Enovia and Delmia for the design and simulation of production environments.

There are also other software capabilities that the company has either developed or acquired in recent years such as simulation, biological and material sciences and virtual reality. The company has a strategy to continue growing these advances into the future.

At a recent press event in London, Stephen Chadwick, managing director, EuroNorth, Dassault Systèmes, outlined what the group sees as the role and capabilities of its 3DExperience software, not only the future of manufacturing but all aspects of life where design plays an important role.

“Dassault Systems is a European company founded on aviation design software Catia, which is now the industry standard for design,” he says. “Our early focus on 3D digital mock-ups meant we could design an individual component but also then put that into a system or a system of systems to build an aircraft or a car or even a shampoo bottle or a garment using the same methodology.

“Later, we developed the term Product Lifecycle Management (PLM) which is the ability to understand a product from the creation stage through to disposal and every other stage in between, so that involves concept, testing and performance through to disposal.

“In 2012 we launched the next ambition which was to become the 3DExperience company. This is essentially about bringing the consumer into the development cycle and how we can we bring multiple industries together to be able to understand the challenges that really affect the world today.

“One example is the car industry. The vast majority of car buyers buy a car because they like the emotional feeling and experience that it gives them, so they have an emotional buy-in to owning that car, whether it’s just going from A-B or whether it fits in with an image they have about themselves.

“The 3DExperience is about using those sorts of feelings and experiences at the design phase in order to create a great experience of a product for the customer or end user.

“This, as you can imagine, spreads through many sectors,” he continues. “From finance to life sciences, from fashion and retail, through to our core industries of aerospace and defence, transport, mobility and industrial equipment. If we focus on the outcome and the experience for the end user, then we can produce a better product. And this in reality means quicker design and fewer design iterations because it is a means getting the best product to market in the most efficient time.”

Mr Chadwick pointed to the example of Jaguar Land Rover where it had partnered with Dassault Systèmes deploying its 3DExperience platform to transform the company’s product development process.

“They have accelerated their transformation through using the 3DExperience platform approach. This means through all the stages of design, from the concept to the detailed phases, through to manufacturing, in-life, and finally disposal, they can develop products that have additional brand value for their business and for the customer.

“So at the early stage of the design process designers have their ideas for the next product but can also get early feedback about what the customer thinks of them. They are also bringing their whole supply chain into this environment so they can have a single data model for the entire development process of a new product.”

Building collaboration

Mr Chadwick said one of the major advantages of the 3DExperience platform was breaking down the ‘silo mentality’ that can affect a company where a lack of communication and cooperation between departments such as the design engineers, production engineers, marketing and the consumer can hinder the development of a product.

Dassault Systèmes is certainly not short of ambition when it comes to the use of its software to improve people’s lives. It is planning to use the 3DExperience platform not just for the development of new products such as aircraft, cars and other consumer products but also for simulating and helping to create ‘smart cities’ and their services including those below ground.

Mr Chadwick concludes: “As a vision for Dassault Systèmes this is what hyper connectivity is all about. We will help build communities in order to create better products and services with improved outcomes for citizens.”

Dassault Systèmes www.3ds.com

Images courtesy Dassault Systèmes