DMG Mori: Live, digital and interactive

For four days, around the globe and with more than 20 live shows in four languages – from 6-9 October 2020, DMG Mori will take the digital stage.

With the premiere of the DMG Mori Digital Event, the machine tool manufacturer offers visitors an interactive platform to experience the latest developments live and virtually. The event begins on 6th October with a virtual firework display of trends and innovations, as well as products and solutions in German. Christian Thönes, chairman of the DMG Mori executive board will open the event with his keynote speech.

7th October, is scheduled for the live presentations in English, followed by presentations for Japan and the USA in the following days. The focus topics include customised automation solutions, digitisation, cutting and additive machining processes – including for medical technology – and innovative product and service solutions with customer-orientated financing options.

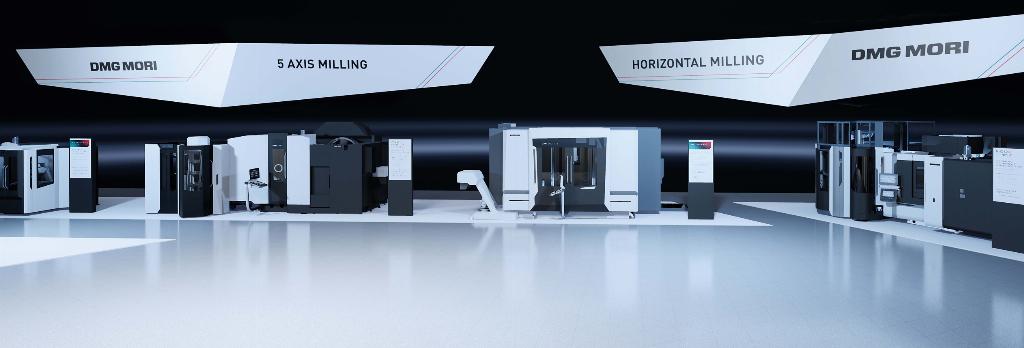

Visitors can look forward to a virtual showroom: a total of 17 high-tech machines and automation solutions can be examined in detail – most notably the world premiere DMF 200|8 and Robo2Go Milling as an innovation in the automation sector.

Virtual live presentations with discussion forum

“Live, digital and interactive – but also typically DMG Mori – as we step into the digital world, taking advantage of the benefits this new virtual platform offers us,” enthuses Irene Bader, director DMG Mori global marketing.

As an integrated 360° solution provider, the company focuses consistently on the further development of digital trends in machine tool construction. In the future, this will also include the presentation of new products and solutions, as demonstrated by the DMG Mori Digital Event and its digital stage.

On the virtual platform, via more than 20 live presentations, the company will present its developments in automation, workpiece and pallet handling as well as turnkey solutions. An additional focus is the area of digitisation and its Digital Manufacturing Package, Tulip and planning and control. During the live presentations, participants will have the opportunity to discuss the following topics in a live chat with DMG Mori experts.

- Kick-off: keynote Speech by Christian Thönes, chairman of the DMG Mori executive board

- Digitisation: flexible entry into digitisation

- Automation: the right automation for every machine

- Additive Manufacturing: end-to-end competence from design to the finished part

- DMG Mori Medical Excellence: medical technology know-how for customised manufacturing solutions

- Service: high availability real and digital

- DMG Mori Finance: strong partner with attractive financing models

Machine presentation in the virtual world

During the event, to enable visitors to experience modern manufacturing technologies live, DMG Mori has created a virtual world in which products and solutions can be experienced digitally. Attendees will also be able to access the Japanese showroom in Iga at the click of a mouse.

Customers are also invited to make appointments with their DMG Mori representatives before and during the show for a one to one experience. The showroom will comprise 17 machine tools including automation solutions, which are shown in detail as true-to-life 3D models.

In addition, the company will showcase an automation solution in the form of Robo2Go, which is now being used for the first time in the milling sector on a DMU 50 3rd generation. The DMF 200|8 5-axis travelling column machine will also be presented as a world premiere. In the future, DMG Mori will continuously expand the virtual showroom.

World premiere: DMF 200|8

With the DMF 200|8, DMG Mori builds on its success with 5-axis travelling column machines which includes IA over 2,700 installed machines over the past 18 years. The new addition ensures maximum flexibility and productivity in key industries such as mould & die, aerospace, medical, and the general subcontracting sector.

The DMF 200|8 features a rigid table measuring 2,300 x 850mm and traverse paths of up to 2,000 x 800 x 850mm, offering ample capacity to machine long structural components or mould inserts. The table load is 2,000 kg. The working area has been increased by more than 50% compared to the previous model. A comprehensive modular system allows application-orientated solutions.

DMG Mori https://digital-event.dmgmori.com/prelaunch?region=en_GB