DMG Mori reveals glimpse of the future at AMB

Traditionally DMG Mori showcases a cross-section of the most innovative technologies when the AMB show in Stuttgart opens its doors to trade visitors from around the world.

With around 30 exhibits from the fields of turning, milling and advanced technologies on an exhibition area of over 2,000m², the machine tool producer will have an impressive presence at the event which runs from September 13th to 19th this year. Some of the innovations on show will include the third generation DMU 50 and the Robo2Go automation solution – which can be used on several machines without any knowledge of robots.

Software solutions

A key building block in DMG Mori’s customer-oriented digitalisation strategy is the app-based CELOS control system, that the machine tool manufacturer first presented around three years ago and which it has continued to develop in a targeted manner ever since.

Using this uniform user interface for machine and office PC, employees on the shopfloor and in job scheduling can manage, document and visualise all job order, process and machine data. Thanks to its open architecture, CELOS allows the exchange of information with higher–level structures in addition to the impact it has in the shopfloor area.

DMG Mori says the software and control offers customers complete integration of their machines in the company organisation while simultaneously creating the interface of metal cutting production in the cyber-physical production system of the future. The benefits in day-to-day operation are convincing: a 30% time saving in tooling times and 50% less time and effort for the calculation of technology values or the search for important information are just a few of the effects that can be achieved with CELOS.

Customers also benefit from further development of the CELOS system, because with every new release DMG Mori implements 50 enhancements. In addition, the machine tool maker will be presenting ten new CELOS Apps at the AMB show. These will include the new CELOS Developer App, with which partners will be able to develop their own APP for the very first time.

Workshop-oriented programming is still of great importance, especially in single item production and the production of small and medium-sized quantities – and it will remain just as important for a long time to come. Working with cycles is state-of-the-art in this respect and the reason why standard cycles in turning, milling and drilling have long been part of the scope of performance of modern controls.

Based on its decades of application experience DMG Mori claims it has gone far beyond the industry standard. It currently has 24 exclusive DMG Mori technology cycles for the fields of turning, turn-milling or rather milling, mill-turning in its portfolio. These enable operators in the workshop to programme even complex machining tasks themselves directly on the machine via a dialog using parameterised context menus which can be up to 60% faster. Notable examples include the machining of free-form surfaces using 5-axis interpolation or various cycles for gear cutting or gearwheel production. Other cycle highlights include the MPC (Machine Protection Control) for the protection of machines, workpiece and tool, the 3D quickSET toolkit for checking and correcting the kinematic accuracy of 4- and 5-axis machines or the Application Tuning Cycle for the process-oriented tuning of feed drives in relation to the table load at the push of a button.

World firsts

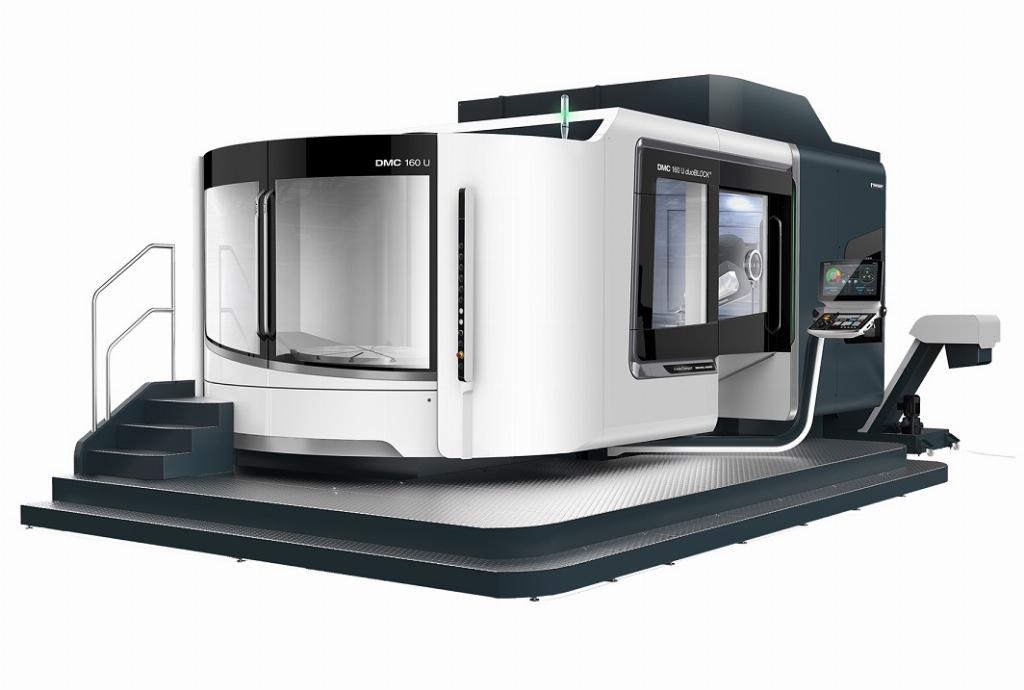

As usual DMG Mori has a number of world premieres of machine tools at AMB. One model is the DMC 160 U duoBLOCK. This 5-axis universal machining centre with pallet changer is based on the proven duoBLOCK principle and in its 4th generation offers 30% more stability and accuracy while at the same time reducing energy consumption by 30%. Innovative highlights of the machine include the new 1,800Nm 5X-torqueMASTER gear spindle and a travel path in the Y-direction that has now been lengthened from 1,250 to 1,600mm.

Heavy-duty machining is now part of routine work in the field of mechanical engineering generally – in the aerospace branch, for example, or the automotive industry for the production of chassis parts and engine blocks. In this respect the sturdy construction of the patented duoBLOCK concept offers the perfect basis for both productive and high-precision machining on the DMC 160 U duoBLOCK. Its extensive cooling measures in the machine bed and base plus its wide linear guides, drives and the spindle also boost the long-term accuracy of this universal machining centre. The pallet changer of the DMC 160 U duoBLOCK can handle workpieces weighing up to 4,000kg, while travel paths of 1,600 x 1,600 x 1,100mm mean the workpieces can also have extremely large dimensions.

Another world premier is the second generation DMC 210 U. Maximum rigidity and long-term accuracy have always been the noteworthy features of the portal machines from DMG Mori. The machine tool manufacturer has optimised these even further in the second general of this successful series. With a large cube-shaped work area and a high-performance spindle programme plus CELOS control in the standard version, the new DMU 210 U is perfectly equipped for the rising demands on the market, according to DMG Mori. Thanks to its numerous equipment options this machine, which will be available just in time for the AMB, is ideally suited for mechanical engineering in general and in particular for sectors such as tool and mould making and aerospace. The large cube-shaped work area with travel paths of 2,100mm in the X and Y directions and 1,250mm in the Z-axis offer ample space here.

The fast and innovative wheel magazine can hold up to 303 tools (SK50/HSK-A100) with lengths of maximum 900mm despite its minimum space requirement. The standard chain magazine has 60 tool pockets and offers the option of holding a 30,000rpm pick-up motor spindle. With a torque of 1,800Nm, 52kW output and 8,000rpm the 5X torqueMASTER is a special highlight among the other available spindles. Thanks to its extended swivel range and optimised interference contour, this gear spindle enables the heavy-duty machining of complex 5-axis components. In addition to its equipment and performance, DMG Mori has also improved the efficiency of the DMU 210 U thus reducing energy costs and making a significant contribution to environmental friendliness.

Another new machine is the fourth generation of the DMU 90 P duoBLOCK. Superior features here include the highly stable design of the universal machine, long-term accuracy and highest precision with up to 4μm positioning accuracy even in the standard version. The DMU 90 P is designed as a package machine with a 430Nm and 52kW motor spindle, space for 60 SK50 tools plus an IKZ coolant unit and guarantees an economical entry into heavy-duty machining.

Applications in tool and mould making as well as in general mechanical engineering call for investment in reliable, high-performance production equipment. DMG Mori has included the attractively priced DMU 90 P duoBLOCK in its range with universal machining in mind. With an X-axis travel path of 900mm and a workpiece weight of 1,800kg, it outperforms the smaller DMU 80 P duoBLOCK. Where its technical equipment is concerned, DMG Mori has concentrated on heavy-duty machining and offers the DMU 90 P duoBLOCK as an appropriately equipped package machine. DMG Mori will be in Hall 7 on stand A01 at the Messe exhibition centre in Stuttgart.

DMG MORI http://uk.dmgmori.com