The road to electric cars leads to new challenges and solutions

Driven by concerns over climate change and growing regulation, the global automotive industry is on its way to the mass adoption of electric cars.

In this article, Beth Rhind, co-founder and executive manager of the World Car Awards, discusses the new challenges and solutions that come with this trend.

Just how fast and how complete that transition will be remains uncertain, but what is already apparent is that it brings with it new challenges for car manufacturers and their suppliers. And with those challenges, new solutions.

For example, contrary to what some people may expect, electric vehicles (EVs) are not inherently silent. Replacing an internal combustion engine (ICE) with one or more electric motors does not so much eliminate overall vehicle noise as change it. Yes, the engine noise we’ve come to expect from ICE-powered automobiles is absent, but in that absence new sound sources arise that need to be addressed.

Electric motors themselves create their own noise, particularly at high frequencies, and electronic controllers emit their own sounds. In addition, eliminating typical combustion engine noise at lower frequencies can make other sounds, such as tire and aerodynamic noise and that from air conditioning and other ancillary systems, even more apparent. It’s a different set of challenges.

There are thermal challenges as well. Not only is there potential for localized component overheating but, without the waste heat from an engine to use, the passenger cabin of an electric vehicle can be significantly more difficult to keep warm and comfortable than that of a vehicle powered by a combustion engine.

Some other challenges aren’t different from those of ICE-powered vehicles but are important for other reasons. Challenges like weight, for example – both overall vehicle weight and that of its individual components.

Reducing weight has long been a goal in vehicles powered by combustion engines to aid in decreasing fuel consumption and emissions. In electric vehicles, reduced weight still pays dividends in terms of lower energy consumption and thus increased driving range with a given battery. But there’s a further multiplier effect.

The heavier the vehicle, the more battery capacity it needs to achieve established range and performance goals. But batteries are heavy, compared to other vehicle components, so adding battery capacity tends to increase vehicle weight disproportionately. It’s a vicious circle that means weight reduction is just as important in an EV as in an ICE vehicle – perhaps more so!

Added to those challenges is that of environmental responsibility for a vehicle and its components throughout its life cycle, from manufacture to disposal. It’s a tall order.

Long-time World Car Awards partner, Autoneum, is very much aware of and on top of those challenges. As innovation leader in acoustic and thermal management, Autoneum already translates its expertise in research and development into products and technologies that meet the requirements of modern mobility, including electromobility.

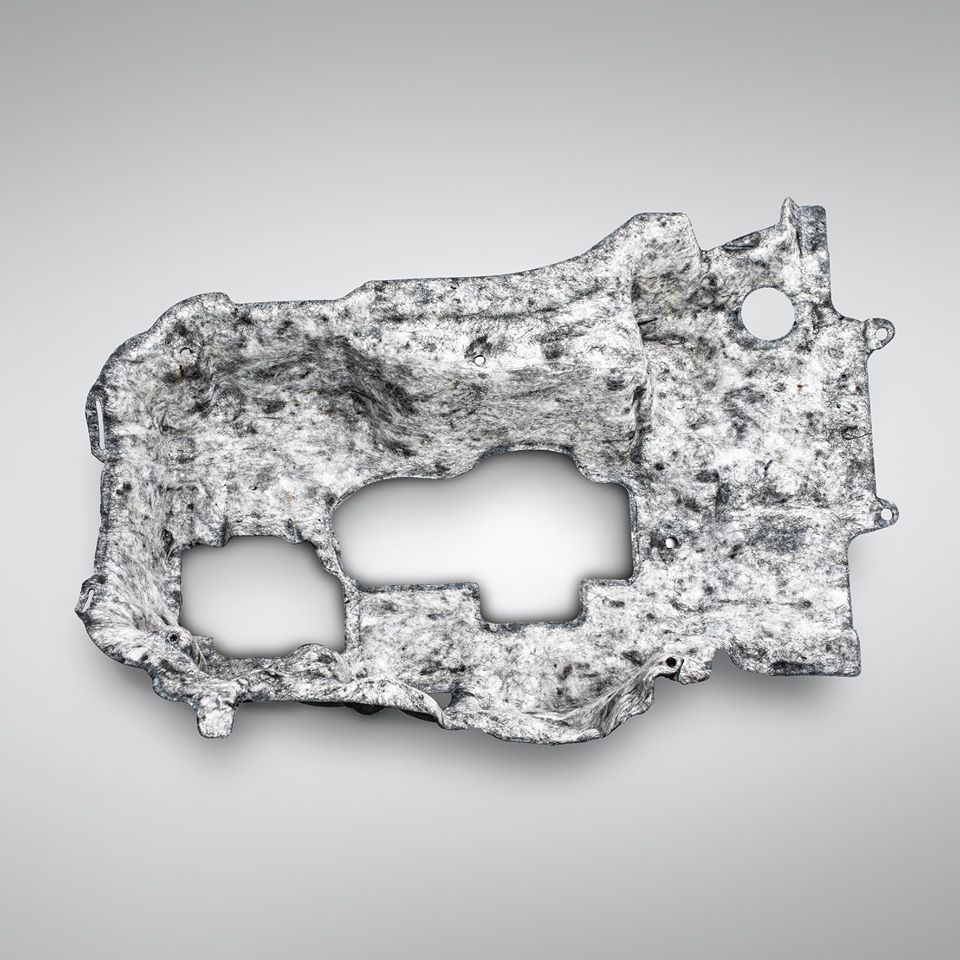

One example of such products is battery compartment undercovers made of Autoneum’s ‘Ultra-Silent’ textile material, which acts as an insulator to help lower sound that enters the passenger cabin as well as pass-by noise. Made of 100% PET fibers, they are as much as 50% lighter than corresponding components made of plastic. When installed underneath the battery casing, they help protect battery cells against significant cooling or heating, contributing to a constant temperature with a correspondingly optimized battery capacity. They are also resistant to water, stone chipping and vibrations and thus help to protect the battery casing.

Other examples include components made of ‘Hybrid-Acoustics PET’ for use in the engine compartment, where they act as insulators and absorbers at the same time. This patented innovation is based on a unique fiber material consisting entirely of PET obtained largely from recycled fibers, thus meeting customer demand for environmentally-friendly mobility solutions.

Among its applications, Hybrid-Acoustics PET is used to encapsulate electric motors, thereby reducing noise directly at the source and particularly attenuating high-frequency sounds of the electric drive unit. Accordingly, this key technology ensures reduced noise levels in the passenger cabin and greater driving comfort.

Compared to conventional insulators, components made of Hybrid-Acoustics PET are up to 40% lighter, thereby contributing to a longer driving range. They are also flameproof and exhibit temperature resistance of up to 180°C. Plus, they are produced waste-free and are completely recyclable – an outstanding life cycle assessment compared to equivalent components in the engine bay.

These examples highlight Autoneum's commitment, as part of its Advance Sustainability Strategy 2025, to continuously improve the environmental performance of its product portfolio and thus contribute to a resource-efficient mobility.

Autoneum www.autoneum.com

World Car Awards www.worldcarawards.com