A profitable pathway to automation

For anyone interested in exploring automation for their manufacturing business’ future, a five-day open house held at FANUC’s UK headquarters in Ansty, Coventry in November presented an abundance of solutions. Ed Hill reports.

At the FANUC open house not only were there a wide range of automation options on view from the Japanese industrial technology OEM, there were also more than 35 partner companies for attendees to interact with at the event.

“We wanted to bring together the best solutions partners that the UK has to offer,” comments Oliver Selby, robotics business manager at FANUC UK. “These companies not only help us in our supply chain but their presence here also shows customers that the whole ecosystem around FANUC amounts to more than just us building and supplying robots and our other manufacturing technologies. It gives visitors a chance to see many of the additional process solutions working in conjunction with our core technologies.”

More than 650 visitors attended the event, which as well as featuring robots, machine tools and IIoT offerings, held a series of seminars and talks on topics such as: the barriers to automation in the UK; industrial strategy and automation adoption; apprenticeships; workforce adaptation to robotics; and the future of automation in relation to artificial intelligence and industrial connectivity or IIoT.

“The talks give us a chance to learn more about the future of automation and the way in which we approach the market,” Mr Selby asserts. “It’s also a way of educating potential customers which is very important. Feedback from audience members allows a two-way discussion and provides us insight into how our customers perceive the situation.”

Now’s the time

So, in a UK manufacturing climate of skills shortages, productivity shortfalls, global competition, Brexit complications and COVID 19, has UK industry finally reached a stage where the benefits of automation have become too difficult to ignore?

“In the Fast Moving Consumer Goods (FMCG) market COVID had a big impact as our customers experienced sudden staff shortages and struggled to cope with the same or increased demand that working from home created,” Mr Selby states. “Although for more industrial applications, such as welding, it is becoming increasingly difficult to find staff with the required skills. We are in a position where automation can provide an ideal solution.”

Mr Selby believes that for new companies automation can easily be adopted from the start but it can be harder for older established businesses who may have difficulty moving away from their legacy working practices.

“Younger engineers don’t have as many reservations and are much more committed to adopting automation, particularly the start-up firms that we work with. Older companies can take longer to make the commitment but they need to adopt it as much as they can. Our experience shows companies that commit to automation substantially are the ones that get the biggest benefit. Dipping your toe in the water isn’t as beneficial. We also find it helps staff to adapt quicker if the move to automation is greater and more committed right from the start.”

So how does FANUC guide its customers on the road to embracing automation?

“Sometimes it means working with those companies at a strategic level rather than just being a provider of automation,” Mr Selby affirms. “After an initial enquiry we do an on-site audit, so from the very start we can tell the customer if a system really is the right solution for them. One key philosophy at FANUC is that we believe in total transparency so if we find automation isn’t the answer, we will be honest. However, the benefit of the audit means we can also help companies identify other opportunities for automation in their production that they may not be aware of.

“If we do supply a system or products through one of our partners, we can help provide training and help develop the company’s core skill set to ensure that the automation is adopted effectively, and a sense of ownership is created within the user’s own workforce.”

Finding funding

Previously, one of the reasons the uptake of robotics and other automation systems, particularly among SMEs in the UK, has been comparatively slow, has been the flexibility in financing options. However, Mr Selby says this is changing meaning that even for shorter contracts it is worth considering.

“We have a lot more partners who offer various supply and financing solutions,” he explains. “If it’s a lower cost automation solution we would look to partner a company with one of our integrators who provide robotics and automation systems in a company’s particular field or process.

“There are of course different ways you can fund an automation acquisition; you can buy a system outright as a capital investment, or you may consider it as an overhead in a lease or renting type scenario. There are options such as hire purchase agreements, equipment leases, financial leases and renting for automation solutions. This can be a good option especially if it’s a standard automation system, such as a robot machine loading cell, because they still have residual value at the end of the lease term.

“Companies who opt for leasing arrangements can buy the machine at the end of the agreement, lease again or return it. It means there is the choice of leasing machines for the duration of a shorter contract or longer if required. We can advise companies on the best options and that is why building trust with our customers in those sorts of situations is important.”

New technology such as collaborative robots (cobots) is another reason automation systems are proving a more viable option for machining subcontractors as they offer greater flexibility, particularly if space is a limiting factor.

“The ability to use one robot across multiple machines is one way in which companies can get better payback for their robot investment,” Mr Selby continues. “Advances like AI and new vision systems are making what have been typically harder scenarios for automation easier to introduce.

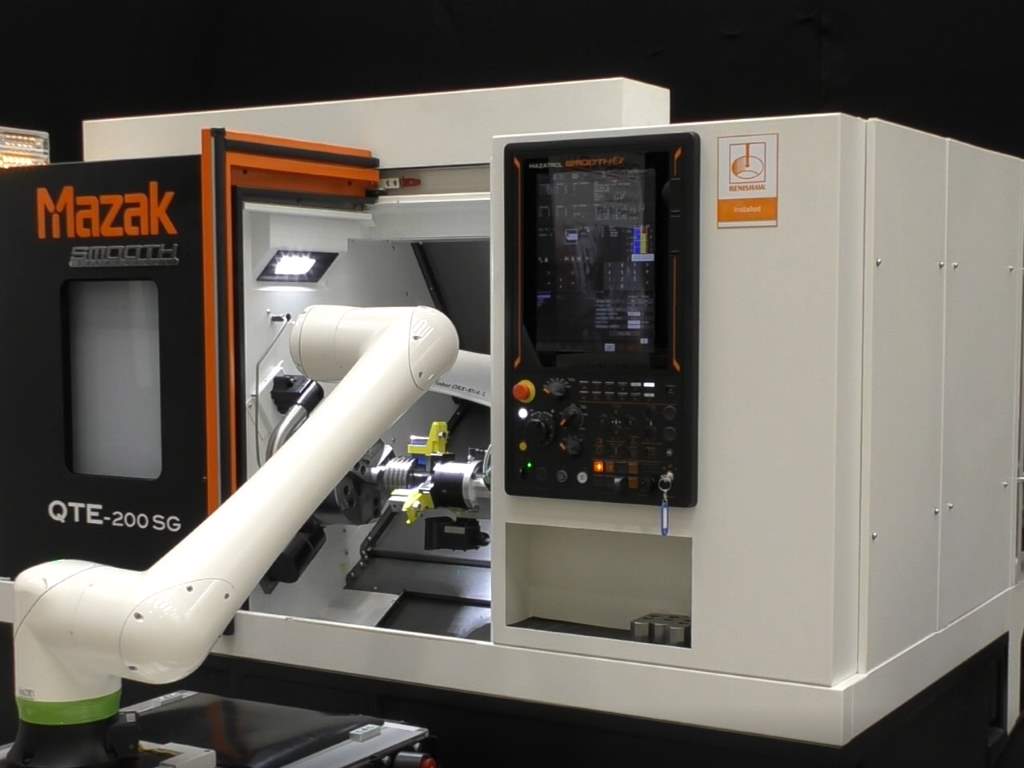

“For example, one of the robot systems being demonstrated here is a very technologically advanced machine tool loading application. It uses a vision system not only to find parts on a pallet but the cobot actually locates itself next to the machine. With this system you can have the robot arm on a movable platform and once the robot is in front of the machine it will calibrate itself and start loading. That is an extremely useful system that is very adaptable for small UK SMEs dealing with relatively small batches. It means they can also benefit from the use of an industrial robot because it offers much more flexibility.”

Working partnerships

According to Mr Selby, FANUC’s approach to supplying automation and robotic systems, whatever the situation, is ultimately a collaboration between themselves, other manufacturing equipment suppliers, and the end user to get the best workable solution.

“We support many machine tool brands to ensure the right solution is offered based upon the needs of the customer. We find that solution from determining throughputs, machining cycle time, space and complexity of product. This analysis provides an idea on the levels of flexibility the customer needs and ultimately effects what we offer and through what means, whether that’s the machine tool dealer, machine builder or directly through us or one of our partners. I would add that machine tool dealers or builders who can offer the latest automation solutions are going to be better placed to sell their machines in future.”

So, what is Mr Selby’s answer to the age-old question; do robots create more or less jobs?

“Definitely more; most companies looking to introduce robots are also seeking to employ a younger workforce, and that younger workforce do not want jobs where they are just loading machine tools. They want more in their future careers which means using modern engineering skills such as programming and supporting higher level devices such as robots and the latest CNC machines tools.

“The nature of new engineering employees is changing. They are being taught how to use CAD/CAM software, rather than using older methods of programming, how to automatically inspect components inside and outside of the machine, and how simulation can be used to optimise processes and increase throughput.”

And FANUC UK itself is looking to change in order to increase automation and robotic implementation.

“We need to be more proactive and find different ways to approach customers, and then educate them in how our new technologies can support their growth and increase efficiencies,” Mr Selby concludes.

“That’s the situation we find ourselves in now, generally trying alongside other key UK stakeholders to increase the awareness of how important automation is and will be going forward. In the end a strong UK manufacturing industry is good for everyone, and should they choose FANUC then all the better!”

FANUC UK

https://www.fanuc.eu/uk