Flexible clamping boost for start-up subcontractor

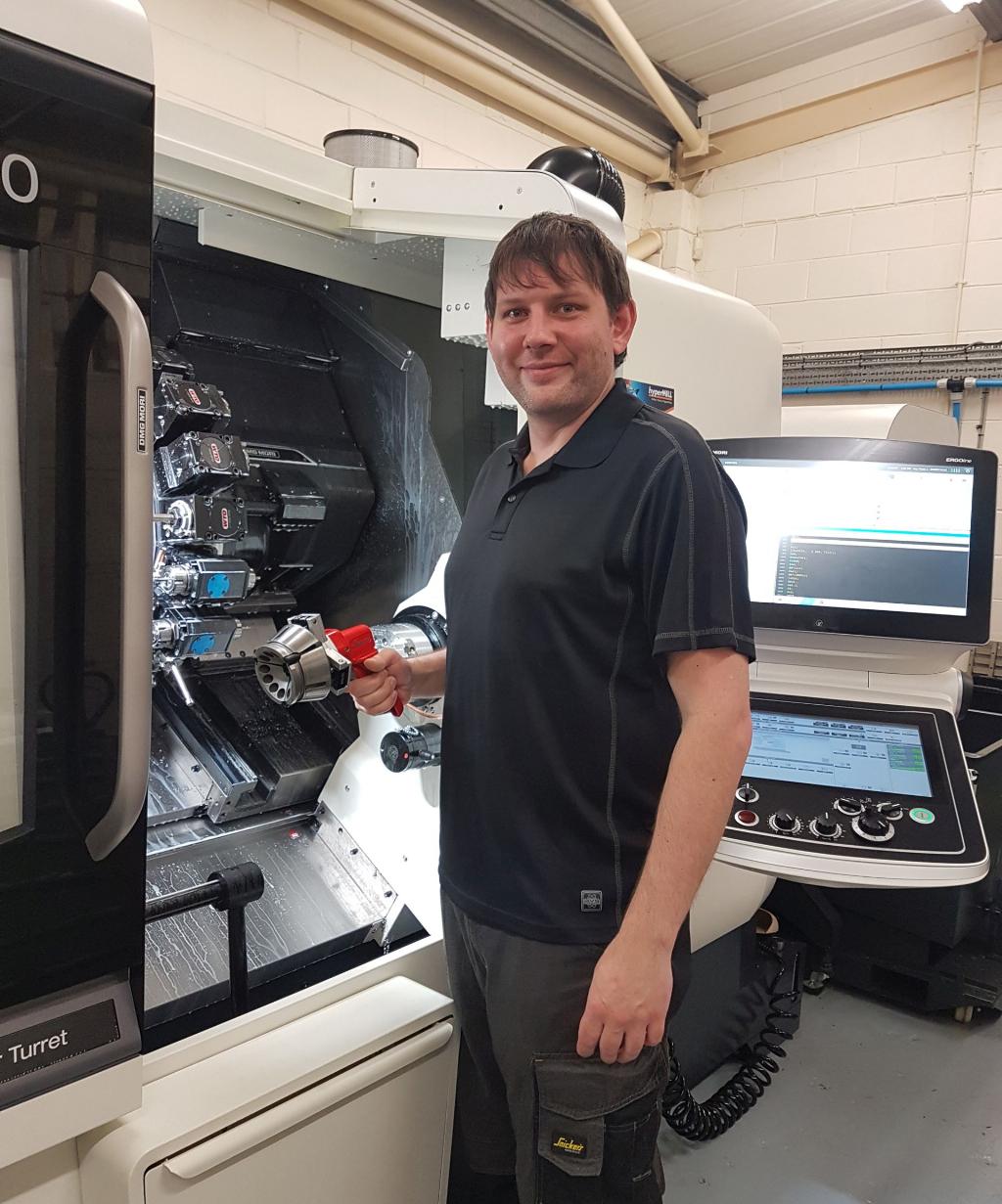

Just over three years ago, deep sea welder and fabricator Ben Goodwin gave up the dangerous day job to start BRG CNC Machining, a subcontract machine shop.

The company was launched with a Hurco 3-axis machining centre and now the company has taken its next step – installing a DMG Mori turning centre with Hainbuch workholding equipment.

The Market Weighton, East Yorkshire start-up has witnessed phenomenal success since it was formed; winning customers in F1 and motorsport, agriculture, utilities, offshore and general subcontract sectors. As BRG CNC Machining has grown and become more successful, Mr Goodwin has always strived to invest profits back into the business. This initially resulted in high-end Open Mind CAM software to drive the Hurco VM10 and more recently the arrival of the DMG Mori NLX2500-700 turning centre.

BRG CNC was turning work away and missing opportunities by not having a CNC turning centre. Mr Goodwin recognised the need for a high-end machine and did his due diligence.

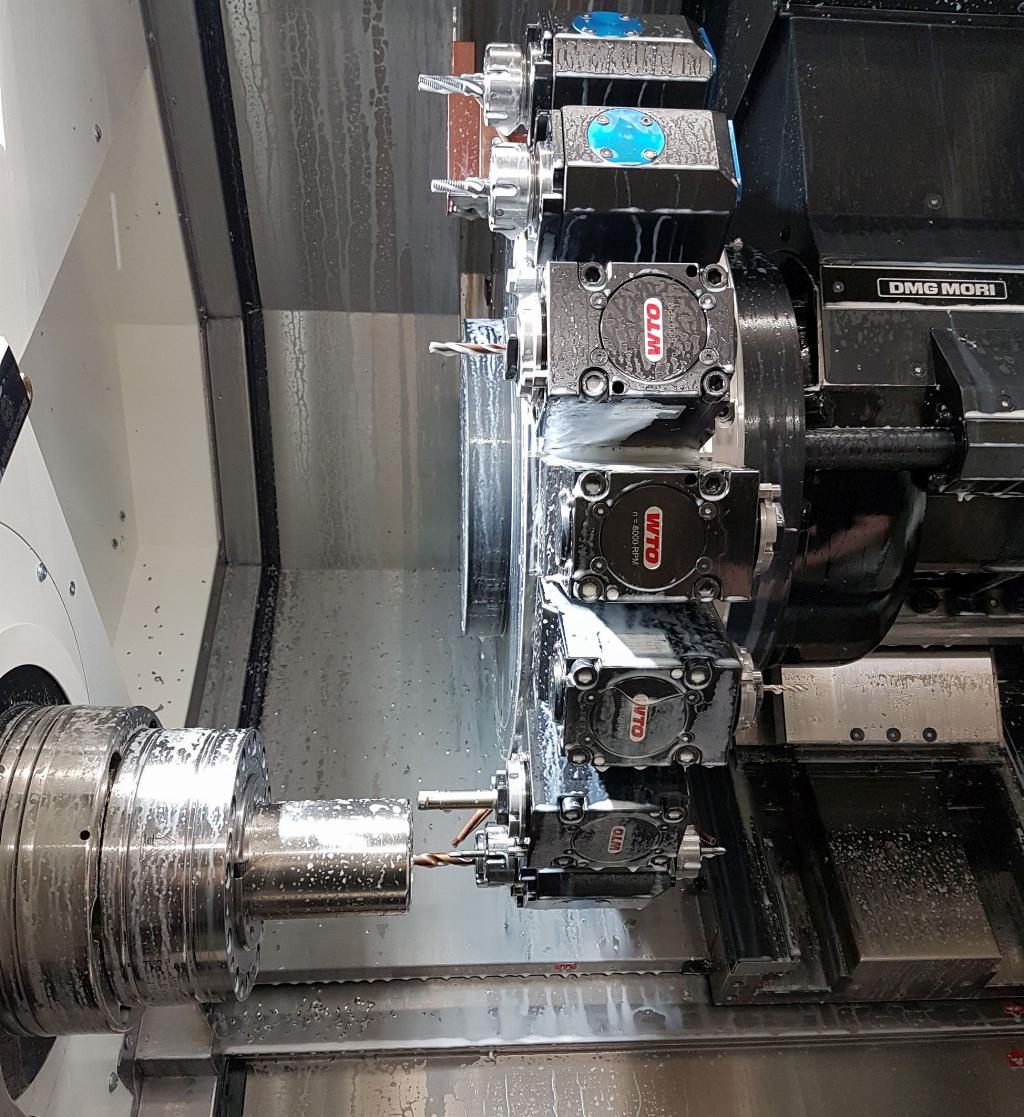

“I wanted a twin-spindle turning centre with a turning capacity up to 80mm that could be bar fed. I spent an age reviewing the options, but the DMG Mori NLX2500-700 was the most productive and robust option for our business,” he says. “I spent thousands on optional extras such as the sub-spindle, Y-axis milling, 70/30 bar coolant and 20 tool position turret to get the most productive turning solution for my business. One key area of investment was the workholding solution for the main spindle – a Hainbuch Spanntop Nova Combi Fix collet chuck.”

Like many subcontract companies, family owned BRG CNC is utilising the new turning centre for highly flexible small and medium batch work. The typical workflow on the new DMG Mori machine involves the machining of a wide variety of parts.

Mr Goodwin comments: “This week we are machining 48-off parts for the utilities sector; 68-off 35mm diameter components for a rape seed drill in the agriculture industry and motorsport components that are an urgent requirement. These parts are manufactured from 7075 aluminium alloy, S155 and EN24 steel, but in the main our work is generally aluminium, stainless and steel.

“To effectively machine the huge diversity of parts that any subcontract company is faced with, we had to have a machine with excellent flexibility and also workholding that facilitates fast changeovers with rigid and high clamping forces. For us, the Hainbuch Spanntop Nova Combi was the only feasible choice.

“We really did our homework on workpiece clamping as we appreciate the impact that rigid, robust and precise clamping can have on both the finished quality of the parts and the performance of the machine and the cutting tools.

“In addition, the engineers at DMG Mori recommended the Hainbuch clamping system. We spoke with Hainbuch engineers and it was their appreciation of our needs, the available options, the support and service that were all key reasons behind our decision to buy the Spanntop Nova.

“We regularly machine 76mm diameter batches of 100-off parts from 304 stainless and the clamping forces of the Spanntop are very impressive. Using the milling turret, we are rough milling parts with a Seco HF end mill at over 6,000mm/minute at a depth of 0.8mm. Clamping the parts on less than 30mm of material, the Spanntop is achieving clamping forces of over 3.5mpa. In comparison, the hydraulic three-jaw chuck on the sub-spindle only attains a clamping force of 1.6mpa. The result of the high clamping force is excellent surface finishes, extended tool life and we are achieving all this whilst running the jobs at speeds and feeds faster than we ever could have imagined.”

The Hainbuch Spanntop Nova Combi can be used with or without an end-stop. This provides the flexibility for turning both chucking parts and bars that are fed from the LNS barfeed. The Spanntop Nova Combi stabilises the workpiece by using its axial draw force to pull the parts against the end-stop, which can be rapidly removed to convert the collet chuck back to a fully functional bar chuck.

“I am blown away by how easy the Hainbuch system is to use. The changeovers are remarkably fast and the construction of the system minimises contamination and the need for cleaning. This guarantees we maintain 100% precision and repeatability.

“We rarely turn anything below 20mm diameter so at present, I have the 25, 60 and 76mm collet adaptors and these cater for almost all my needs. However, I will be investing in further adaptors in the near future. We can also see the clear benefits and differences between the Hainbuch Spanntop Combi on the main spindle and the 3-jaw hydraulic chuck on the sub-spindle. As and when we start getting more work that requires back-end working, we’ll definitely be adding a Hainbuch system to the sub-spindle too,” Mr Goodwin concludes.

Hainbuch www.hainbuch.com

BRG CNC Machining www.brgcnc.co.uk