Getting into gear manufacturing

A pair of one-day seminars on gear manufacturing was held at NCMT’s Coventry technical centre and showroom on 27th and 28th June.

Over 70 visitors learnt that it is possible to achieve world-leading accuracy when producing gears and splines on standard machine tools built by Okuma, Japan, whose products are sold in the UK and Ireland exclusively by NCMT.

The company’s engineering director Adrian Maughan said: “There is an increasing interest in producing gearboxes that are more compact, lighter and more efficient. The flexibility, high productivity and lower investment cost offered by producing gears on 5-axis machining centres or multi-tasking lathes from Okuma, coupled with their high levels of accuracy and repeatability, makes them ideal for the purpose.

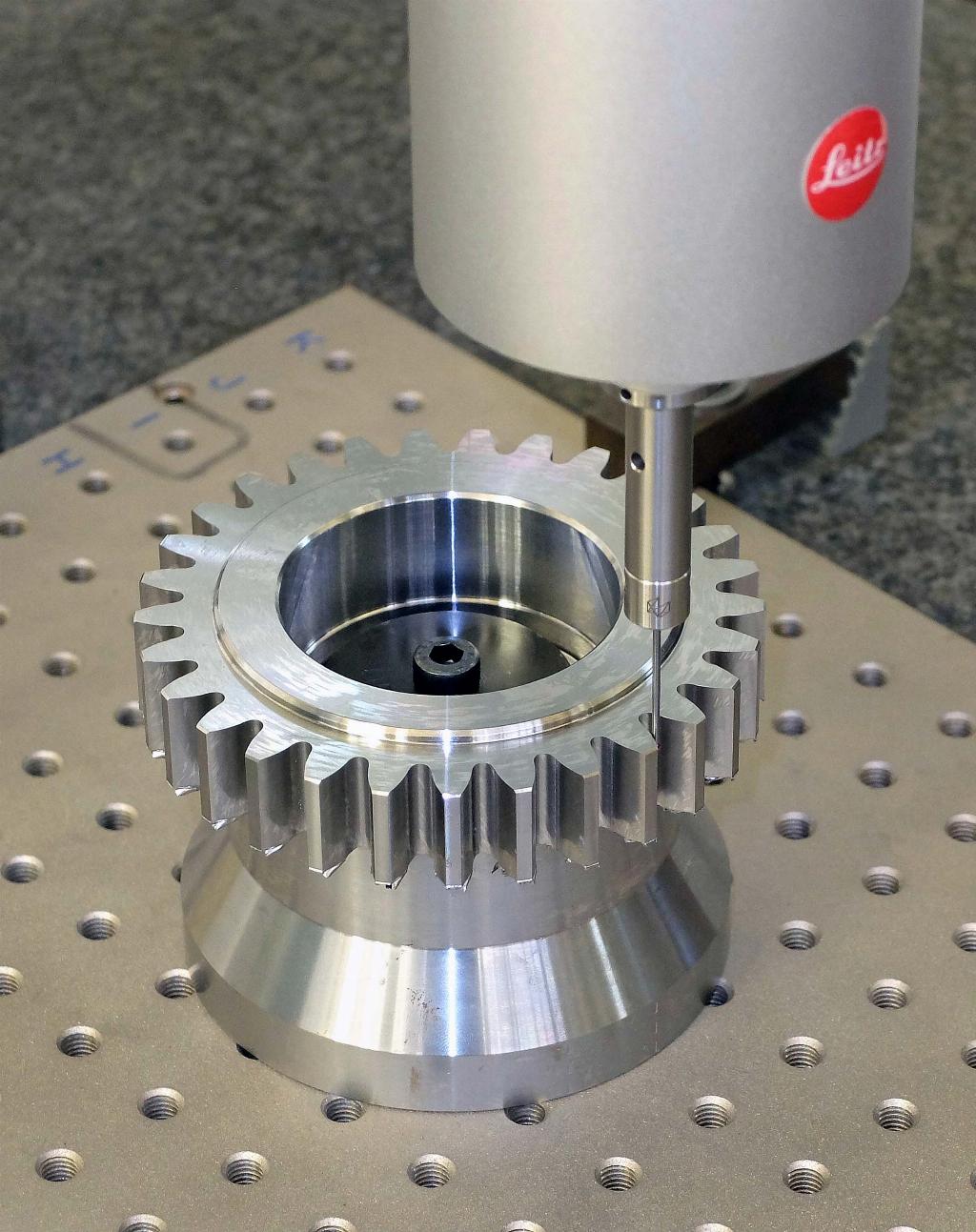

“We not only showed the wide range of external and internal gear types that can be machined but also proved the high level of precision attained by measuring them on our recently installed Leitz CMM equipped with the latest Quindos software.”

NCMT believes that the combination of hardware and software offered on standard Okuma machines places the company at the forefront of gear production on a multi-tasking platform. Demonstrations at the seminars were performed on a Multus U3000 2SW turn-mill centre, while power skiving also ran on an MU4000V-L 5-axis vertical machining centre.

Power skiving is intended for producing gears in large volumes to high accuracy using a dedicated tool for each type and size of gear. The skiving tool sequentially roughs and finishes the component. The 3.9 module spur gear produced during the demonstrations had a deep tooth profile that requires robust machine tools to skive the finished product from a solid billet.

NCMT proved on its Leitz CMM that a Class 6 spur gear was achieved by power skiving on the Multus machine. Accurate synchronisation between rotation of the tool and the workpiece is essential to achieve this level of accuracy.

Another process demonstrated was InvoMilling, a flexible machining technique as it is capable of producing different gears using the same standard milling tool. Helical and spur gears ranging from module 2 to 12 can be produced with just two tools, for example. Other tools are available to cover a module range of 0.5 to 100.

This process is ideal for prototyping and small to medium batch production, as well as for producing larger modules, pinions and complex gears such as a herring bone with gap.

There is no limitation to the root form due to the use of standard tools. This means it is possible to save many weeks in manufacturing lead-time by not having to wait for special tools to be delivered.

Other gear production techniques and their relative benefits were covered during the presentations, including hobbing using a carbide inserted cutter, shaping and spiral bevel milling.

NCMT www.ncmt.co.uk