Brake the mould

Whether straddling a 1,000cc superbike hurtling at 200mph toward one of the countless turns of the 37.7-mile Isle of Man TT mountain course, somewhere in the Mexican desert approaching the Ensenada finish line after 20 plus hours running non-stop in the gruelling Baja 1000 or pedalling a bicycle down a steep, rocky descent having just landed a drop off at the Mont-Sainte-Anne course in the Mountain Bike World Cup, probably top of the list of components where failure isn’t an option are braking systems.

EBC Brakes has been manufacturing high performance braking components at its Northampton world headquarters for nearly 40 years. In addition to the brakes used in various racing classes, EBC produce a comprehensive range for road cars, motorbikes and bicycles, both as a standard series built to OEM specs, and oversized brakes to increase performance.

Central to EBC’s production are its Haas machines as machine shop manager Vince Goosey elaborates: “We chose Haas because we love the fact the machines are built in the USA. As a company that is built around manufacturing in the UK and the US, we want to choose machine suppliers that align with our company ethos. Investing in Haas – who were selected over a number of competitors – has allowed us to take full control of our manufacturing process, allowing us to machine all components in-house.”

The Haas DS-30 Super Speed dual-spindle lathe is used to machine the disc hubs of the two-piece discs for the car side of the business and allows turning of both sides and drilling of mounting holes live.

The two-piece disc, a steel rotor with an aluminium hub, is used predominantly to save weight and improve brake discs performance at the extreme temperatures seen on track or during fast road driving. To solve the issue of the rotor fluctuating in size as it heats or cools, EBC uses a SD (square drive) system, allowing the rotor to slide against the hub as it expands or contracts therefore avoid warping.

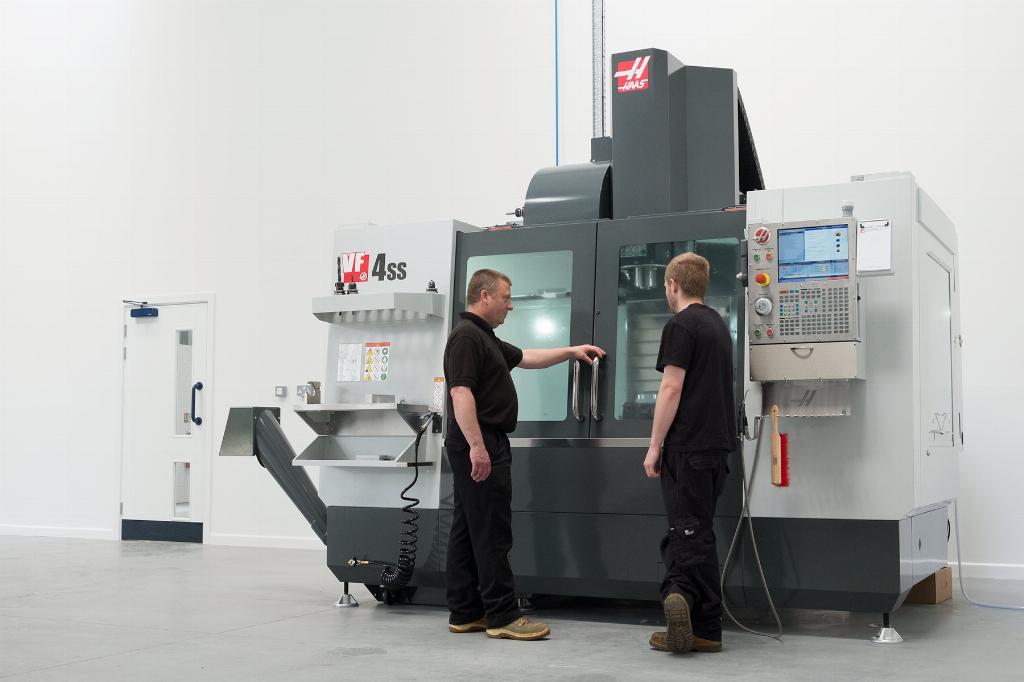

The DS-30 is then supported by the new Haas VF-2SS and VF-4SS vertical machining centres, purchased in April 2017, which are housed in the factory's brand-new facility; the EBC Centre of Excellence.

This state-of-the-art machine shop will be used as an R&D tool and also for production for EBC’s new line of performance brake calipers and two-piece discs. The new building will raise manufacturing capacity for automotive brake discs, incorporating a brake caliper production and assembly line with a larger warehouse and also a new research and development facility, all playing an integral part in moving the business forward; boosting the company’s global brand status.

UK manufacturing is hugely important to EBC, which produces 100% of its own motorcycle brake discs and rotors at the UK facility, along with 100% of its brake pad range made in its UK and USA factories. A high proportion of its automotive brake discs are also UK and USA made.

Haas UK www.haas.co.uk

EBC Brakes www.ebcbrakes.com