Hainbuch extends range with Docklock zero-point clamping

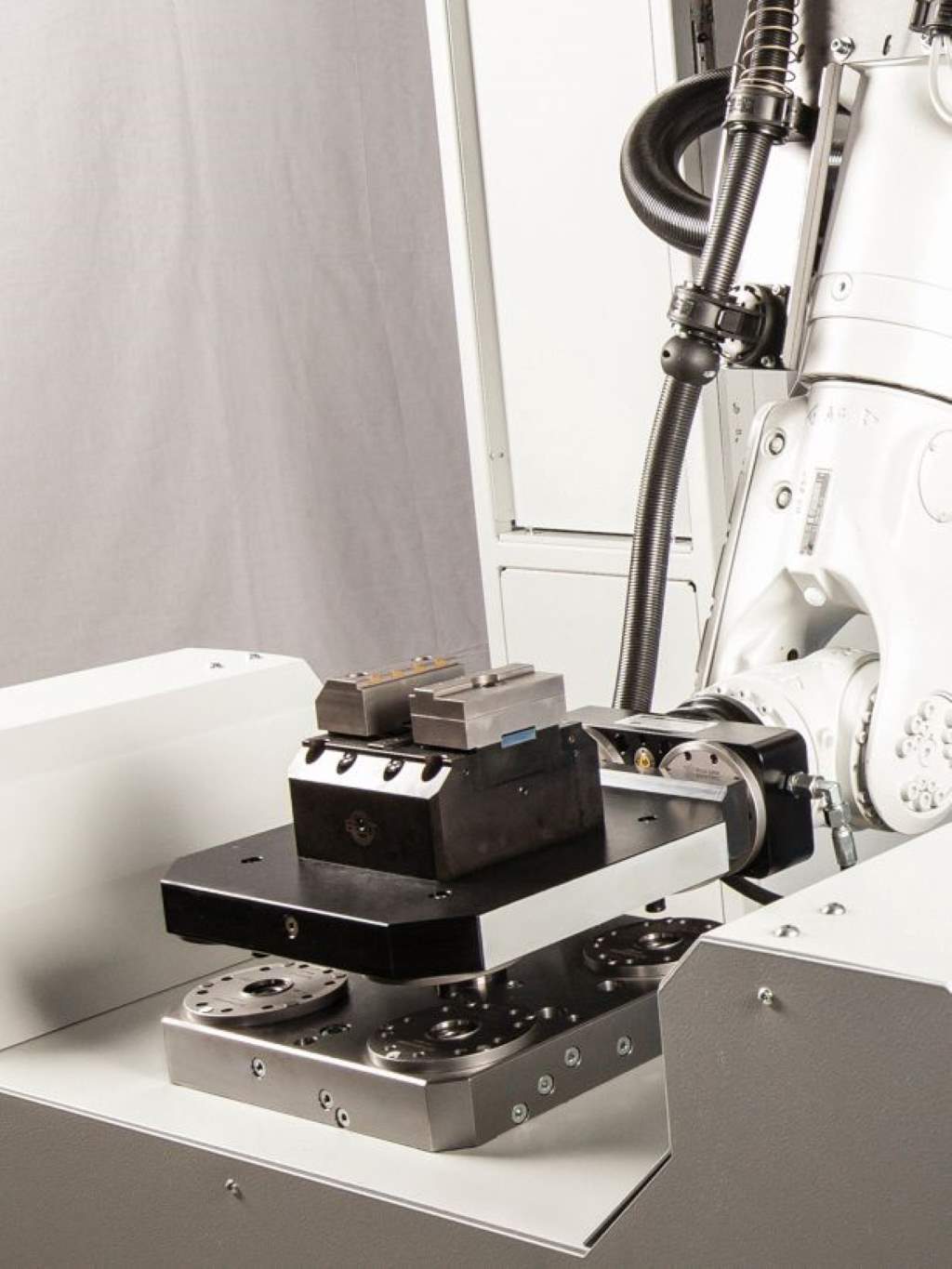

To strengthen its position even further in the area of stationary systems, Hainbuch, a manufacturer of high-precision clamping devices, has acquired the Docklock zero-point clamping system from Vischer & Bolli AG in Switzerland.

The Docklock system has been on the market for more than 20 years and its reputation in the stationary workholding field is long established. Its features and user benefits match perfectly with Hainbuch's product philosophy – products must be easy to use, process-optimising, easy to set up, long-lasting and precise.

Hainbuch has offered quick changeover or zero-point clamping systems for lathes for many years, and now it is expanding its capabilities in the area of stationary systems. The four variants of the Docklock system now have Hainbuch branding. Both pneumatic and hydraulic variants are available for either manual or automated changeover.

The Docklock zero-point clamping system has two advantages over other systems. The first is form fit clamping with a collet or clamping segments, ensuring rigid clamping and high repeatability. This also means that there are no pressure marks on the clamping bolt compared to systems with balls or slides, which lead to inaccuracies and consequently the need to replace the clamping bolts.

Secondly, it is impervious to dirt and swarf which means less wear and less maintenance. The base plate, which is screwed onto the machine table, provides the base for a quick changeover. The zero-point repeatability is ≤ 0.005mm without alignment. The clamping device combined with the Docklock, can be changed over in two minutes ensuring significant savings in production time and cost.

Using the interface, setup can be performed outside the machine avoiding lost production. The collet chuck lock ensures trouble-free insertion and removal of the workpiece pallets. Direct installation on machine tables, pallets or fixtures can be implemented cost-effectively by means of flanged cylinders which is less expensive than a plate changer or a machine table changeover.

The form fit clamping and power transmission design features are identical to the Docklock for manual changeover. The same applies to the changeover time and zero-point repeatability. In addition, an automatic shutter at the clamping point prevents ingress of dirt and swarf which ensures even less wear and less maintenance. It also has as standard features, contact control, air-blast support islands and piston monitoring for a safe automated process.

Hainbuch UK

www.hainbuch.co.uk