Transformation time

Hone-All Precision, a leading supplier of deep hole boring, deep hole drilling, CNC turning and honing services, has, like many companies, endured a long and challenging year but has remained open and operational throughout the pandemic. A notable highlight for the Leighton Buzzard subcontractor however has been embarking on the Sharing in Growth Scheme. PES reports.

Hone-All’s 40 strong team has always specialised in manufacturing high precision, tubular components for a wide variety of industries but things have changed over the past year with a decline in business from the oil and gas and aerospace sectors.

Fortunately, other industries such as defence and hydraulics have remained buoyant and with the commitment of its close and long-serving team, the company has remained fully open and operational throughout even the most testing and dangerous times of the lockdowns.

“Our team have been absolutely amazing in their commitment to COVID safety and ensuring we can continue supplying our customers throughout the pandemic,” says company director, Andrea Wilson.

“We’re really proud to say that we haven’t had a single outbreak or requirement to isolate from within the factory. For such a small, close knit team working in close proximity, this shows a real awareness and respect for the safety and health of others and it’s testament to the family-like working relationships we have within the business.

“Many of us have ‘grown up’ together and witnessed the development of our lives and families over the last 20-30 years and we have celebrated a huge amount of work anniversaries lately – including service achievements of 33 years, 26 years and 25 years. Three members of staff celebrated 20 years in the first quarter of 2021, and more are due later this year.

Sharing in Growth

A recent development for Hone-All is passing the initial due diligence stages of the Sharing in Growth scheme which hopefully, once the diagnostics are completed, will give the company access to a three-year business improvement and transformation programme which is fully government funded and simply requires a commitment to matched time from the business.

The Sharing in Growth scheme was established in 2013 to provide intensive transformation support to accelerate business growth. With origins in aerospace, clients support all the key manufacturing growth sectors including offshore wind, defence, and nuclear – all sectors Hone-All is familiar with and working within.

To date, the Sharing in Growth team has secured £5.2 billion in contracts, 9,100 jobs and assisted over 80 companies. In 2020, the organisation won the Princess Royal Training Award for Outstanding Training and Skills Development.

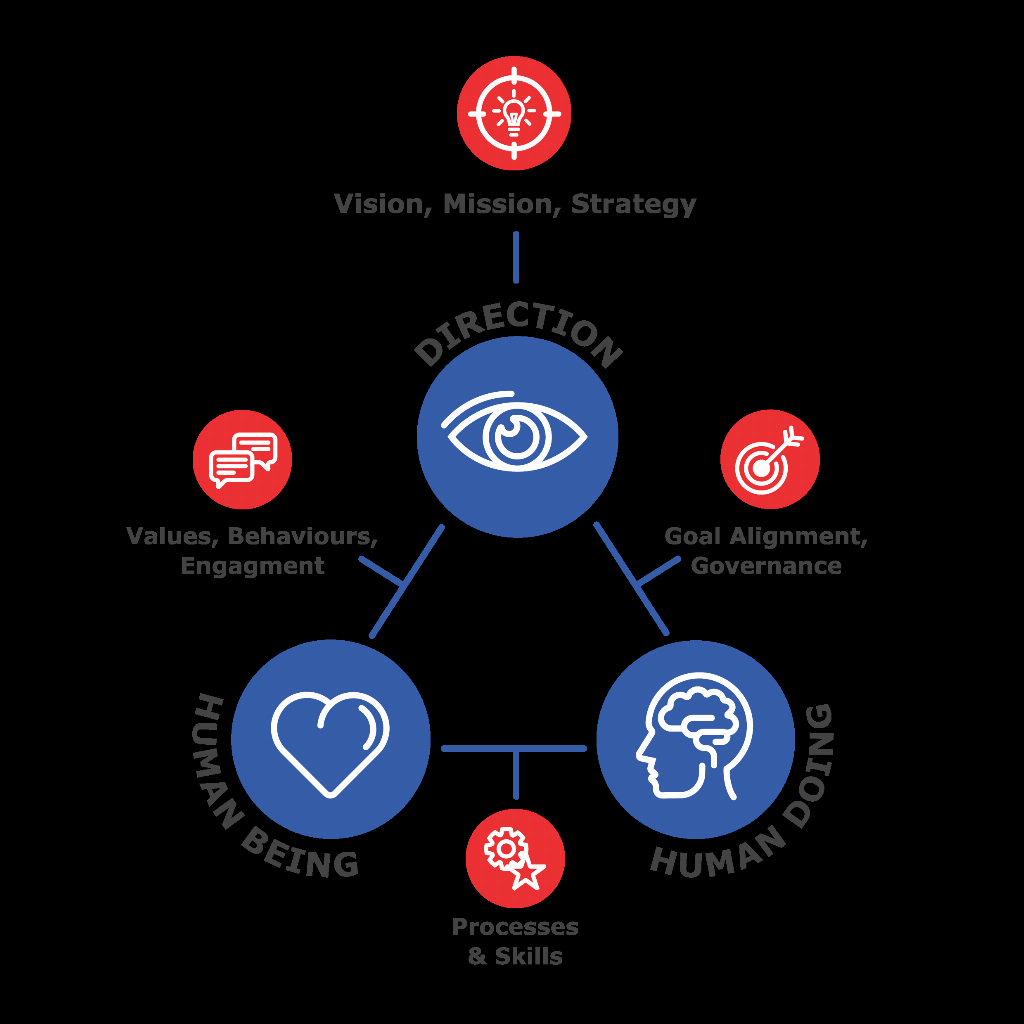

Its philosophy balances the need to drive clarity of purpose and the environment to get work done efficiently, while increasing the engagement of the team. This approach has been proven to succeed at both company and value stream levels.

Hone-All has been proactive by applying for this funding as the usual qualification criteria stipulates a sales turnover of in excess of £10 million – a figure Hone-All is aspiring to reach by the end of the decade through continuous investment and development across all elements of the business.

Andrea Wilson continues: “We are thrilled to have passed these initial stages for the Sharing in Growth scheme as we’ve heard so many fantastic reports about the team, the benefits they bring and the results they’re achieving. We know it’s a big commitment, but we are all prepared and can’t wait to embrace the challenges ahead as we know and appreciate the opportunities this scheme could bring to our business.

“We already have an outstanding approach to excellence and a level of compliance and attention to detail which verges on the OCD scale, so I’m told by previous auditors, but this will facilitate access to a huge team of highly experienced industry experts with a proven record of success.

“SME’s can rarely access this type of funding, particularly to this level of business transformation and the fact we have got to this stage in a short space of time is testament to our staff, our knowledge and expertise, and our commitment to continuous improvement to be the best we possibly can,” she affirms.

More visibility required

Other precision subcontract engineering businesses that have benefited from this scheme include JJ Churchill with a £70 million contract win, Castle Precision Engineering with a record £80 million order, and TMD Technologies which is now enjoying a 64% gain in productivity.

Andrew Churchill from JJ Churchill says of the scheme: “Sharing in Growth is an excellent example of the Government and manufacturing working together to make our industry more effective, more efficient and futureproof. This is increasing opportunity, sales and jobs.”

“At a time when the Industrial strategy has been scrapped in favour of a new ‘plan for growth scheme’ it’s encouraging to hear that the Government is supporting businesses through schemes like Sharing in Growth – but it does need to be better publicised. We only heard about it through a recommendation made by a Make UK board member,” Ms Wilson advises.

“Expansive, immersive and longer-term initiatives like this are what the manufacturing industry needs right now. The majority of SME schemes are short-term, single improvement project focused which although have their place within certain businesses, do not offer the opportunity to develop longer term relationships with the coaches or business transformation teams which inevitably leads to a greater understanding and improved business performance.

“They also cost more to administer by the delivering teams as the due diligence process and documentation requirements are the same whether the project lasts a month or three years. It makes sense to look at longer term schemes with a wider coverage of processes within the business.

“Hopefully, if Hone-All can succeed on the Sharing in Growth scheme we can be a catalyst for change and inform and improve the Government’s attitude towards helping SMEs, ultimately leading to a longer term strategy for support, irrespective of company size.”

Hone-All www.hone-all.co.uk

Sharing in Growth www.sig-uk.org