CNC machining firm invests to keep up with reshoring demand

British engineering firms are in increasing demand from major multinational companies looking to bring more work back to the UK from Europe and China, according to the boss of a busy Derbyshire CNC machining business.

Paul Cobb, managing director at HPC Services in Ilkeston is looking to capitalise on this trend by investing more than £600,000 on a trio of new machines from the Engineering Technology Group (ETG) to help accelerate production as it looks to keep pace with rising customer interest.

The company is now operating 45 CNC controlled milling and turning machines, while the machining side of the business is currently employing 80 of the firm’s 150 workers and turnover has hit £8 million.

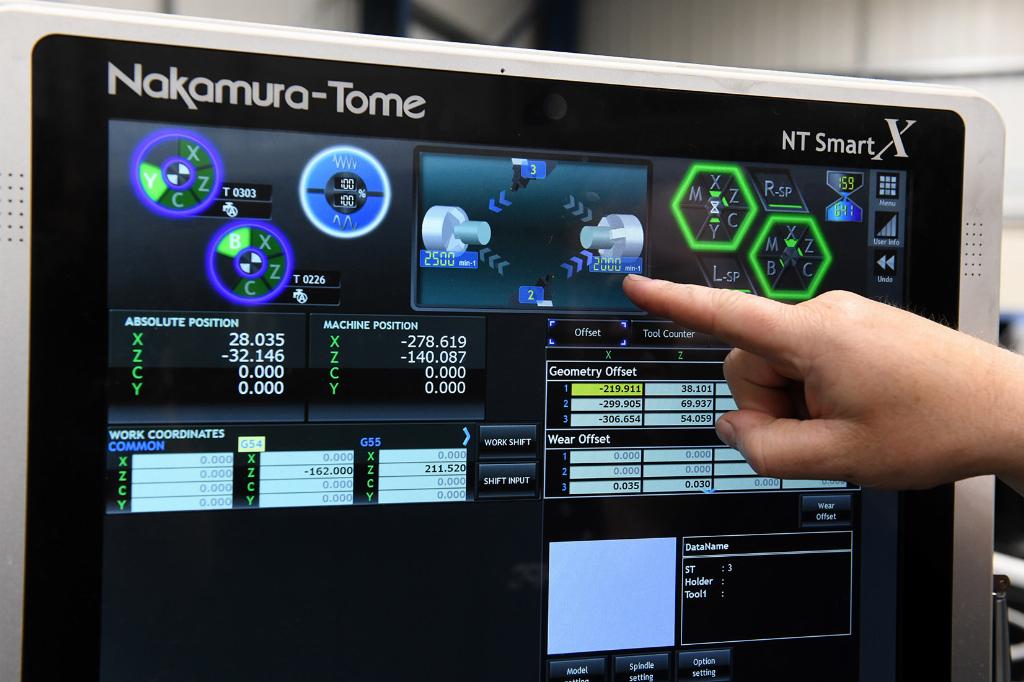

The latest additions to the set-up are a trio of Nakamura machines – two WT150s and a WT100 - that are already boosting the speed of production.

Mr Cobb says: “The WT150 has twin spindles and twin turrets which makes it hugely versatile. As a subcontractor you don’t really know what is going to come through the door on any day, so these machines are almost the optimum for us. We mostly use them for producing milled components on medium sized production runs from a few hundred parts to a few thousand – that’s the sweet spot for us.

“The Nakamura machines are incredibly reliable, accurate and very quick. Compared to the machine they are replacing, which was turning out a part in seven minutes 35 seconds; they can do it in just three minutes and 50 seconds.”

He continues: “They can operate on parts up to 65mm in diameter, which is quite large, and we have linked them up to an automatic rotary conveyor. We can run them 24-hours a day on aluminium or brass parts and around 18 hours a day on stainless steel.

“The machines are productive and very accurate – importantly, we can now just feed the CAD details into the machines and away they go.”

Mr Cobb started HPC in 1997, which is now part of the Hemlock Group, founded by his late father in 1986, and things are currently on a high.

“Demand has been huge; we have seen no sign of a slowdown over the last year on all sides of the business. Better still it is coming from a very wide range of industries.”

Some of the company’s work is coming back from China, with many of the multinationals looking around and choosing to place work in the UK. It is the same with orders coming from the EU, with customers opting to make a strategic choice by placing work with subcontractors who can offer fast lead-times and repeatable quality.

“It’s because we can deliver what they need in terms of speed and quality. Price is important too, but it’s secondary,” Mr Cobb adds.

“That is why reliability is so important and working with the Engineering Technology Group means we don’t have to worry. That is very important to us.”

Jon Mannion, regional sales manager at Engineering Technology Group, added his support: “Nakamura technology has really grown in popularity in the UK, with many subcontract manufacturers switching on to the outstanding performance and value for money it offers.

“I have worked with Paul for many years and understand his enthusiasm for Nakamura’s range of machines. It is the automatic choice for people who are looking for a quality-built machine that can in turn produce high quality parts quickly and can be programmed for lights-out operations.”

He concludes: “The WT150II provides up to 26kW of cutting power available for turning shaft work with synchronised spindles, whilst the driven-tool motor power is suited for heavy cutting with very small tools.”

Engineering Technology Group (ETG) delivers highly productive turnkey solutions to customers involved in automotive, aerospace, domestic goods, high-value engineering, medical and oil and gas.

Its portfolio of brands includes Bavius, Hardinge Bridgeport, Chiron, Nakamura, Quaser and Stama.

HPC Services www.slidinghead.com

Engineering Technology Group www.engtechgroup.com