Cost-effective inspection for the automotive industry

ArcelorMittal Tailored Blanks (AMTB) Birmingham is a subsidiary of the global group ArcelorMittal, a leading supplier of laser welded and unwelded blanks for the automotive industry.

ArcelorMittal Tailored Blanks (AMTB) Birmingham is a subsidiary of the global group ArcelorMittal, a leading supplier of laser welded and unwelded blanks for the automotive industry.

ArcelorMittal is a global steel and mining company with a presence in 60 countries and an industrial footprint in 19 countries. The company is a leading supplier of quality steel in the major global steel markets including automotive, construction, household appliances and packaging.

About one fifth of global car production is made from ArcelorMittal steel. The company develops automotive steel products to optimise the weight and cost of vehicles, reduce carbon emissions and ensure high standards of safety. Customers include Mercedes, BMW, Volkswagen, Toyota, PSA Groupe (including Peugeot, Vauxhall, Opel), the Renault-Nissan-Mitsubishi Group, Honda and Volvo.

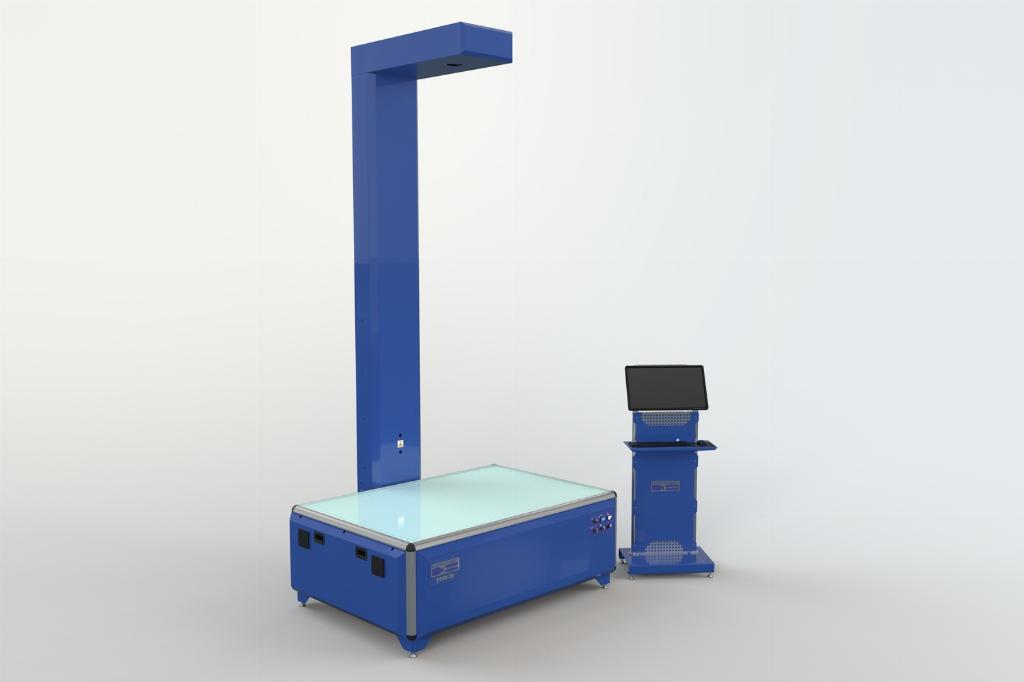

AMTB Birmingham has recently installed an InspecVision Planar 2D inspection system. This marks the tenth Planar machine to be installed at AMTB plants worldwide in the last four years.

Johan Van Oudenhove, senior projects manager at ArcelorMittal Tailored Blanks headquarters in Merelbeke, Belgium, says that parts in all the group’s plants were being checked with callipers. However, as new tighter requirements were introduced it became too time consuming to continue using this method for quality control. Satisfying customer demand meant a new computerised measuring system was needed.

According to ArcelorMittal’s quality control technician at the company’s Zaragoza plant in Spain, 2D full inspection needed expensive CMM equipment, took a long time and wasn’t suitable for the shopfloor so a project was launched to research the solutions available on the market.

This led to ArcelorMittal engineers seeing the InspecVision Planar machine at EuroBlech, the international sheet metal working technology exhibition which takes place in Hannover, Germany.

The first Planar P220.35 machine was installed in 2015 at an ArcelorMittal plant in Genk, Belgium. The quality control manager there commented at the time: “The machine is a helpful tool that measures blank contours in a fast and easy way without programming. The machine is user-friendly and operators can easily check their own production.”

Furthermore between 150-300 parts a week are inspected at each AMTB plant. Since installi

ng the Planar machine, inspection time has reduced by 5-10 minutes per part and for complex parts an hour has been saved.

Previously ArcelorMittal was spending between 13 and 50 hours a week inspecting parts, therefore it wasn’t difficult to justify installing a Planar machine at its plants as it provided a completely new capability of measurement.

AMTB is now able to inspect at least three times more parts on the Planar than was possible with previous manual methods. The machine at the Genk plant had such a positive impact for the business that a further two machines were purchased in 2015 for the plants at Lorraine in France and Gent in Belgium.

In fact, in 2016 ArcelorMittal bought two more machines for its facilities in Liege, Belgium and Zaragoza in Spain, followed by a further four machines for an ArcelorMittal Gonvamma joint venture in Loudi, Chongquing, Shenyang and Changshu in China.

Within the ArcelorMittal Group the Planar machines are used by shopfloor blanking and welding line operators, product auditors and quality technicians.

Mr Van Oudenhove says: “The machine has performed well with no problems in a factory floor environment and customers are very satisfied when it is shown to them during audits or visits.”

InspecVision claims, as well as being extremely easy to use and very competitively priced, that the Planar is the world’s fastest 2D measurement and reverse engineering system.

The company, based just north of Belfast, designs and manufactures a range of both 2D and 3D precision inspection machines for industrial applications which require minimal maintenance and training and ensure a rapid return on investment.

InspecVision www.inspecvision.com