Kasto extends digital networking capabilities

In today’s Industry 4.0 era, digitalisation and networking are rapidly gaining ground to make manufacturing more efficient, flexible and cost-efficient.

Manually-operated islands of production are giving way to continuously controlled, intelligent material flow whereby all elements communicate with each other autonomously. Similar is happening in computer controlled storage and metal sawing, which are often the first two processes in a factory.

The use of mobile devices is also gaining ground in industrial production. With this in mind, Kasto has introduced a new application, KASTOapp, to facilitate remote visualisation of its sawing machines on a shopfloor.

The app displays the operational status of all networked machines equipped with the manufacturer's proprietary SmartControl, AdvancedControl, ProControl or ExpertControl systems.

Users can see the name, machine number and type of saw at a glance. If a machine is running in automated mode, KASTOapp can also access the information stored in the program that is running. It provides users with exact information on relevant parameters such as the item, cut length, target and actual quantities, band feed rate and cutting speed. If a fault occurs, the app displays a graphic of the relevant error message, enabling users to quickly visualise the problem and react immediately to minimise downtimes.

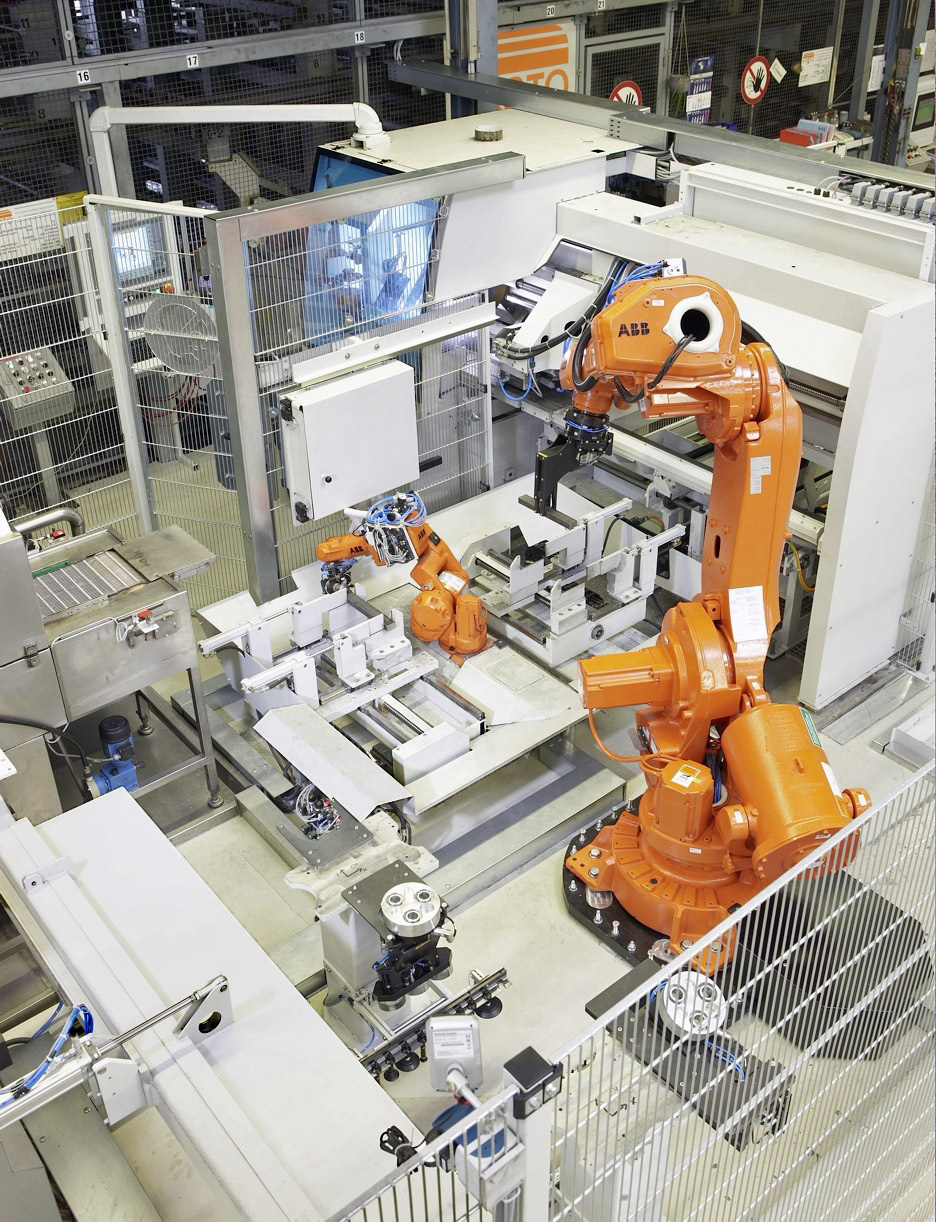

Robot-assisted sawing for greater efficiency

Kasto also has a solution, KASTOsort robot link, to automate production processes upstream and downstream of the sawing process and integrate them into a uniformly-controlled material flow. Industrial robots can not only remove sawn parts independently, but may also perform additional tasks such as deburring, chamfering, centring, threading, marking, printing, sorting, stacking and picking.

This robotic solution can be further integrated with a container management or driverless transport system. Depending on the customer’s requirements, Kasto can integrate the robot control into either the saw's CNC system, or its own KASTOlogic WMS, or an existing ERP system, enabling users to monitor and control the process with a single interface.

Industry 4.0 integration

Quality standards are rising and there is continuous pressure to cut costs. To hold their own against international competitors, UK and Irish companies need versatile and efficient solutions for a wide variety of production tasks. One solution is to ensure that all process-relevant data is recorded and analysed, enabling users to optimise their entire value chain in a decentralised, autonomous and demand-orientated manner. The route from raw material to the finished product becomes shorter, more flexible, resource-saving and less expensive.

Sawing machines, for example, can be seamlessly connected to a raw material warehouse and supplied with the required long stock or sheet materials using manipulators and conveyor technology. Software optimises processes in and around the warehouse, making intralogistics faster and more reliable and travel routes more efficient by avoiding empty runs and placing items that are needed more often closer to storage and retrieval stations. The sawing process itself runs autonomously if the machine is equipped accordingly.

Thanks to customised interfaces ranging from SAP, Infor and Microsoft Dynamics to customer-specific software solutions, the KASTOlogic warehouse management system (WMS) can be easily connected to a higher-level host system within the company, as can individual Kasto sawing machine controls.

The resulting communication structure significantly increases transparency. Users can control orders, while the data collected and recorded in the sawing machines and storage systems can be comprehensively analysed and utilised.

It enables continuous tracking of material and workpieces and uniform utilisation of sawing machines and other machine tools along the production route, shortening non-productive times, improving quality control and enhancing maintenance planning. Even remnant lengths and warehouse stocks can be sustainably optimised with relevant information, reducing production costs further.

Kasto www.kasto.com