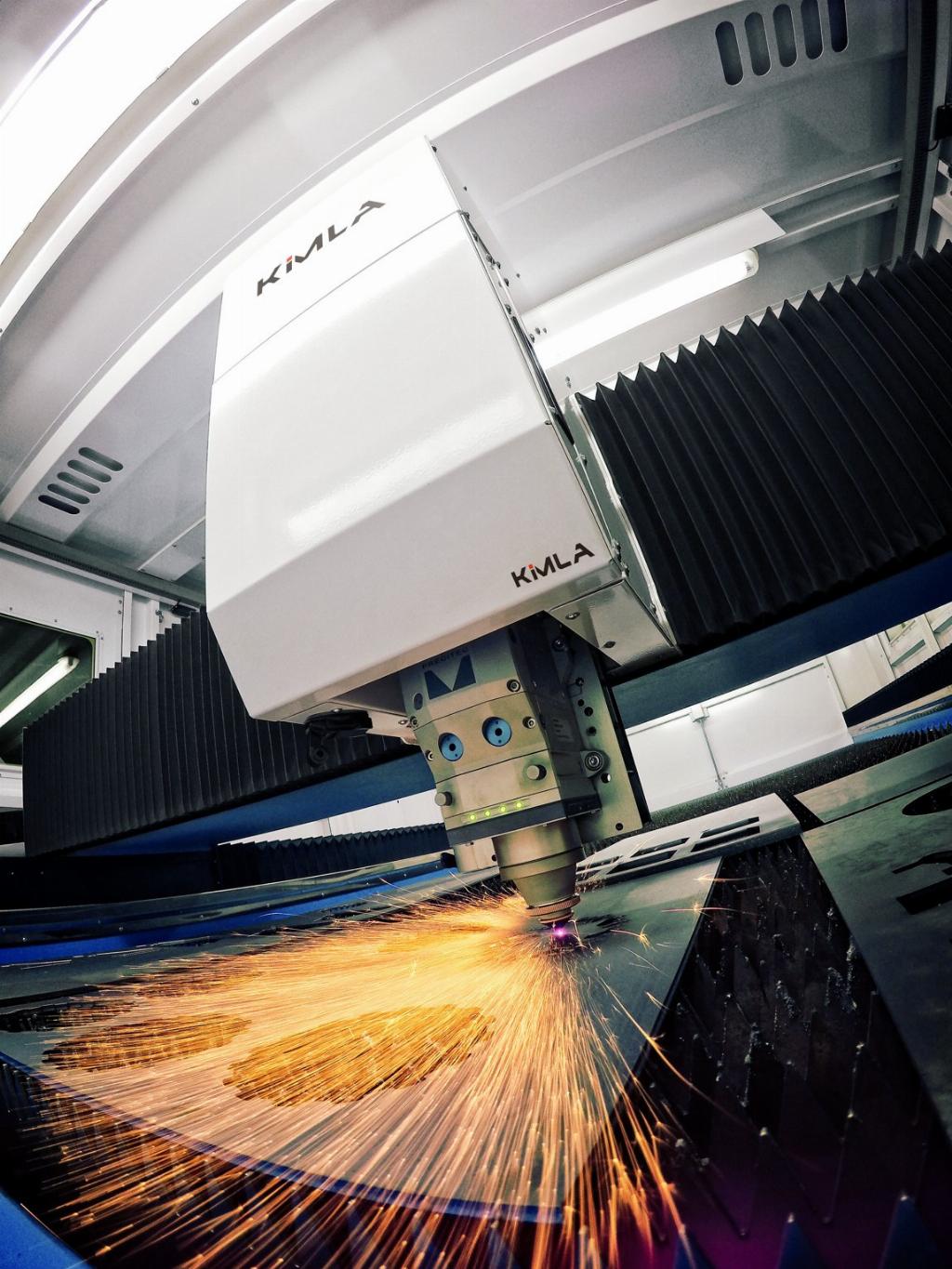

We went to Poland to learn about Kimla's range of laser cutters

Although relatively new in the UK, Kimla lasers have made a big impact on the market since they were launched in 2014. Ed Hill visited the factory in Poland to hear about the company’s passion for its products and philosophy of in-house manufacturing and engineering.

Progressive laser-tech with a Polish twist

Although relatively new in the UK, Kimla lasers have made a big impact on the market since they were launched in 2014. Ed Hill visited the factory in Poland to hear about the company’s passion for its products and philosophy of in-house manufacturing and engineering.

The flatbed laser cutting market is dominated by a handful of well-established manufacturers supplying the UK, but in recent times another European entrant has been making waves with its own distinctive brand of machines that offer high levels of performance.

Kimla fibre lasers built in Częstochowa, Poland (and available in the UK from Wetherby, Yorkshire-based MBA Engineering) are claimed to be the fastest in the market, largely thanks to innovations introduced by the company’s founder and owner Przemyslaw Kimla.

Already an electronics whizz-kid at the age of 18, Mr Kimla began the company around 25 years ago, initially designing and making his own CNC system and software for machines making PCBs.

However, he soon realised that his new control could be used for other manufacturing machinery such as milling machines, waterjet cutters, routers and lasers.

Now the Polish manufacturer has more than 200 staff making a wide range of equipment used in applications including metal cutting and milling, leather, wood and composite processing as well as dental implants.

Aside from fibre lasers, the Kimla name can be seen on a range of CNC machine tools, 5-axis gantry milling machines, flatbed cutters, waterjets and engravers. The product range continues to expand, and the company has sold more than 3,500 machines exported to all corners of the globe.

Quicker control

In recent years the company has made the most strides in its laser cutting technology. Mr Kimla realised that his rapid CNC linked to a new fibre laser could have a big impact on the market.

The control uses what is described as ‘dynamic vector analysis’ (DVA) which means it can achieve extremely fast processing speeds (15,000 lines of G-code/second) allowing precise motion along the axes of 5m/second and acceleration rates up to 6G.

The machines also use Kimla-designed and built linear motor drives offering smooth operation, high efficiency and extreme accuracy. In fact, nearly all the components in Kimla machines are built in-house – the only exception being the laser itself which is supplied by IPG Photonics.

Although Mr Kimla’s company first started manufacturing router and milling machines using his CNC control, the arrival of more efficient fibre laser technology compared to the traditional CO₂ was an opportunity to completely transform lasers from the ground up.

“We could go back to the drawing board and get the maximum benefits from the development of the fibre laser,” he explains. A fibre laser can cut ten times faster than a milling machine so it’s mad not to use a control system that is capable of achieving these kinds of speeds if you can. Other manufactures were wasting the advantages of using fibre lasers by pairing them with older control systems.”

Launched at EuroBlech in 2014, the Kimla machines impressed visitors with the speed they could cut thin sheetmetal.

“We were cutting eight, 4mm diameter holes in 1.5mm stainless steel per second,” Mr Kimla says. “The first time we showed the machines at EuroBlech people were amazed by how fast they were cutting. Our video had to include a clock because people couldn’t believe the machine was cutting in real time.”

Kimla has four ranges of flatbed machines, mostly reflecting the power of the laser: the entry-level Finecut 2kW machine; up to 4kW Flashcut; up to 8kW Powercut and up to 12kW Extremecut. All machines can have variants within these ranges with different power sources and table sizes. The company has also recently developed a machine for cutting longer square section and tube materials.

An in-house production

Every aspect of the design and construction of Kimla machines is overseen by the company’s founder and its design team. The moving parts are mounted on a welded, highly rigid monolithic body. The linear guide surfaces of each of these bodies, or frames, is then precision milled on one of the largest milling machines in Europe.

Additionally, the cutting head’s drives and motion controls are made up of aerospace inspired components intended to reduce weight and allow faster dynamics when moving over the table.

Anyone touring the Kimla factory can’t fail to be impressed by the company’s comprehensive approach to its engineering. Design, electronics, machining, coating, assembly and testing are all carried out under one roof and the company believes this is also a selling point for attracting new orders.

“If customers visit our factory 99% of the time they place an order,” Mr Kimla asserts. “This is because we can demonstrate the main factors they have to consider before buying. Namely, we have the most efficient laser, our machines are well-engineered, reliable and very competitively priced and lastly, without question, they have the cheapest operating costs.”

The company is keen to emphasise that although lasers are complex and can develop faults, because of their robust construction Kimla machines are also economical when it comes to service and support. The developers have also added new Industry 4.0 technology to help pre-emptive maintenance and support.

“Lasers are one of the most complicated CNC machines in manufacturing,” Mr Kimla explains. “A milling machine operates relatively simply along its toolpath, driven by its motors, but a laser has to control and synchronise the modulation of the laser, the focal point, the distance, speed and direction that the workhead travels, the ratio of gas and piercing characteristics. If just one of these factors is incorrect then the laser will stop cutting.

“We have concentrated on developing the cutting head to make it more reliable. We have incorporated sensors and metrology devices that can give us information about the condition of the cutting head. The system monitors temperature and a small infra-red camera constantly looks at the surface of the laser’s lens because it only takes a tiny particle to make it overheat and destroy the optics.

“We can also link these systems to the Internet so the machines can be monitored remotely and we can advise the customer about what they need to do when it comes to service or repair.”

Balance of power

Although the trend is to produce lasers with ever-more powerful power sources, the extra power does not always pay dividends Mr Kimla argues. There is a balance between the amount, thickness and type of material the user is cutting and the additional investment, ongoing costs and ROI that a more powerful laser presents.

“For very thin sheet metal, power virtually makes no difference at all,” he says. “The efficiency of the machine is the most important factor. For thicker materials power is important but it might be more cost-effective to invest in two 6kw machines rather than one 12kW machine if you are mainly cutting material in the 6-10mm range.”

Another Kimla feature is the fact that the machine’s controls include CAD/CAM, nesting and CNC functions; meaning cost calculations for producing parts can be made on the shopfloor.

“We are the first company to design a machine control system which contains all the CAD/CAM/nesting and CNC modules needed to cut and cost a part, so you can design, modify and nest parts on the control and calculate the cutting speed, the exact amount of nitrogen, oxygen or energy you are going to use. You can input the material being cut, the batch size and thickness. All these can be collated to calculate the cost of producing the part.”

When in full flow Kimla lasers certainly look impressive and the company is not resting on its laurels to make its sheet metal cutting even more productive. Kimla’s automated loading and unloading systems can also be added to the machines. In fact the term ‘continuous improvement’ seems the most appropriate when describing the heart of the business and the ethos of the founder.

He concludes: “My motivation is to constantly consider what is the best new component for my machines and how it will improve their performance. Will it make it better than before and better than our competitors?

“The next question is how to cost that improvement and balance the price with the better performance? We have made great advances so far; my goal is to always keep innovating and improving.”

MBA Engineering https://mba-eng.co.uk

Kimla https://kimla.pl