Kloeckner cuts through with new laser

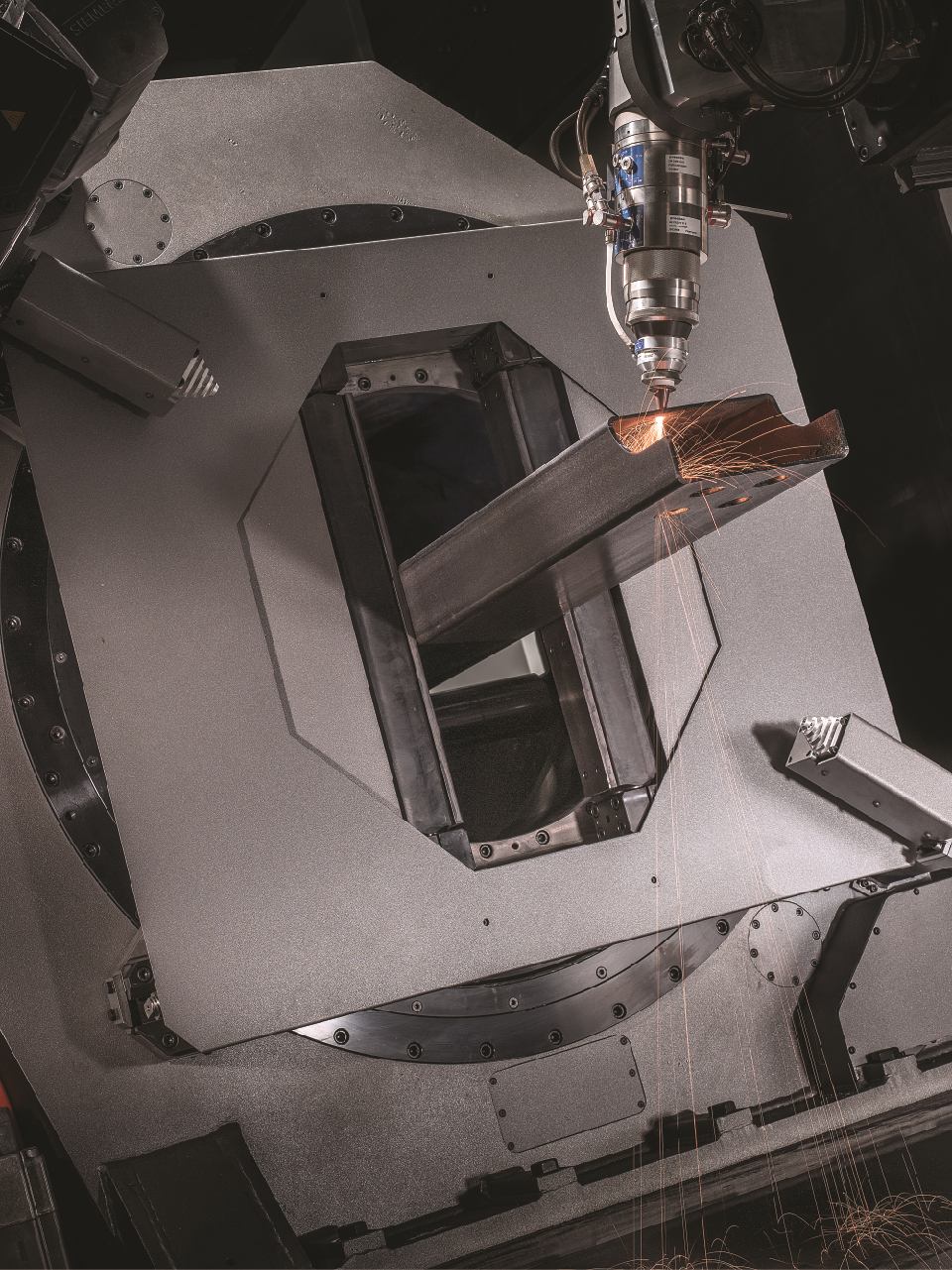

Kloeckner Metals UK, one of the leading tube laser processing providers in the UK, is set to grow its capacity with the addition of new Adige LT14 Jumbo laser to its already extensive laser cutting portfolio.

Kloeckner Metals UK, one of the leading tube laser processing providers in the UK, is set to grow its capacity with the addition of new Adige LT14 Jumbo laser to its already extensive laser cutting portfolio.

Having this machine available will mean that Kloeckner will be one of only a few businesses in the UK capable of processing parts up to 355mm in diameter and weight up to 100kg/m. In addition to processing hollow section tubes, it can also process large beams, columns, split tees, angles and channels.

The Adige LT14 Jumbo laser cutting machine offers a number of operational advantages: it has a 4.5kW Rofin CO2 laser source with the ability to laser cut 20mm thick mild steel and weld prep 16mm thick mild steel material up to 45°; it features a touchscreen interface and uses an operating system that is up to 30% faster than previous versions; it is programmed using the latest version of Artube 3 CAD software which can now import full 3D models/assemblies including IFC files (Tekla), step, IGES and X_T. Also, loading and unloading capability is 15.5m infeed and 15.5m outfeed – the first for an LT14 in the UK.

Clint Jones, Kloeckner Metals UK’s group commercial director stated: “We are delighted with this new edition to our processing portfolio. The advantages and versatility of the new LT14 laser processing machine will significantly increase Kloeckner’s production capabilities and enable us to better service various sectors such as construction, transport and energy markets which require larger processed parts.

“By having these extensive processing capabilities under one roof allows us to offer our customers high quality parts, in shorter lead-times to the specifications required.”

Kloeckner Metals UK www.kloecknermetalsuk.com