Preview of some of the exhibitors at MACH 2020

In the lead up to manufacturing technology exhibition, MACH 2020, here's a preview of some of the exhibitors attendees will find at the show.

In the lead up to manufacturing technology exhibition, MACH 2020, here's a preview of some of the exhibitors attendees will find at the show.

1,000 tasks – one solution

The Bimeric servo-controlled production and assembly system from German manufacturer Otto Bihler Maschinenfabrik is the ideal platform for a flexible and cost-efficient sub-assembly production.

The compact modular Bimeric system is ideal for small and medium lot sizes and situation where product mix is high. With efficient flow production from raw material to installation-ready assemblies, users can achieve consistently high product quality and save additional machines. State-of-the-art servo and control technology ensures maximum process reliability and short set-up times and allow users to react flexibly and quickly to customer requirements.

Equipped with standardised processing modules such as material feeder, press unit, forming units and pick and place units the Bimeric covers a large variety of sub-assembly applications for a wide range of industries such as automotive, electronics, and HVAC components.

For most product and version variations only the component-specific active tool parts are changed on the respective processing units. Afterwards, all that needs to be done is invoking the production parameters programmed in the VC 1 control system.

If additional process steps are required for further applications, Bihler offers standardised servo-controlled processing modules for contact welding, tapping, adding screws, and bunkering plastic parts. The clear division of the individual processing stations ensures excellent accessibility to each individual station for retrofitting and maintenance operations.

With the integrated VariControl VC 1 control platform even the most complex automation solutions can be handled comfortably and intuitively on the Bimeric. All machine functions as well as the number of axes and axis movements are configured directly on the controller without external programming devices.

Changeover procedures are completed easily on the customised menu and are 100% reproducible. The bASSIST multimedia diagnostic and online help system supports operators with videos and graphics, and facilitates process optimisation at any time.

Bihler

www.bihler.de

Stand H20-410

MACH-2020

Marketing health check at MACH

At this year’s MACH show, 4CM is offering exhibitors and visitors looking to grow their businesses a free marketing health check.

Industrial manufacturing and engineering businesses who would like to understand what they could change in their marketing efforts to have the biggest impact are invited to visit the 4CM stand to speak to an industrial marketing specialist.

4CM has over 35 years’ experience working on behalf of the manufacturing and engineering industry with a combination of global clients such as 3M, SKF, Citizen and Suez as well as SMEs such as First Graphene, Pryor Technologies and Boge Compressors.

Nick Brooks, the company’s managing director says: “We’re exhibiting at MACH 2020 so that we can help both fellow exhibitors and visitors with any marketing challenges they may have. In fact, we’re offering a free on-stand marketing health check.

“All they need to do is visit the 4CM website 4cm.co.uk/mach-2020 to request a meeting and we will have our team of experts available to diagnose what could be holding them back from meeting their business objectives.

“Events such as MACH are a great way for manufacturers to engage face-to-face with their target audiences, but we often find that when they get back to the office, momentum is lost in making the most of the leads they’ve gathered. 4CM is a full-service agency so, as well as offering strategic marketing, we can also support lead nurturing and inbound and account-based marketing.

“So if you want to know how you can get to that key prospect you’ve been trying to engage with, improve SEO to drive enquiries and generate leads or understand how to get the most from central marketing to create impact in your local market, request an appointment or visit us at the NEC in April.”

4CM

www.4cm.co.uk

Stand H19-900

MACH-2020

Technology trail

Through its seven centres throughout the UK, the High Value Manufacturing (HVM) Catapult is the go-to place for manufacturing technologies in the UK, supporting organisations of all sizes in their success. The good news is that the HVM Catapult will be exhibiting at MACH this year.

Its Catapult Trail, consisting of four stands across the exhibition, will demonstrate how it can help companies harness key Industry 4.0 technologies to improve their bottom line. All seven of the HVM Catapult’s world-leading centres of innovation will be on display along the trail, with special features on the future of machining, additive manufacturing, digitalisation and automation.

With the continued push in the sector towards (near) net shape manufacturing, the Manufacturing Technology Centre’s (MTC) expertise in additive manufacturing will be on show, with a cutting-edge carbon fibre printer producing components throughout the event.

Making their way along the trail to the Advanced Forming Research Centre’s (AFRC) stand, visitors can then discuss Machining 4.0. This is an Interreg-funded project for SMEs to innovate with new machining technologies, including hybrid systems.

To complete the journey along the supply chain, the Catapult Trail ends with the Advanced Manufacturing Research Centre’s (AMRC) display of its automation and digitalisation capabilities. On the stand, visitors will see an eye-catching Caterham sports car which forms the centrepiece of the AMRC’s ELLI (ELectrification and Lightweighting in Industry 4.0) project. Demos will tie into an overarching digital twin, providing real-time manufacturing data.

Dick Elsy, chief executive of the HVM Catapult says: “Since 2011, the HVM Catapult has worked with thousands of companies of all sizes to raise their game through innovation. It’s right that we are part of MACH 2020 to connect with more manufacturers we can help along the road to success.

“Our team of specialists will be on hand across the Catapult Trail to help you achieve step-change in your company’s performance.”

MTA CEO James Selka adds: “This is a fantastic addition to MACH 2020 and another good reason to attend the UK’s national manufacturing exhibition. We’re so pleased to have such strong support from the HVM Catapult network; they play an integral role in ensure UK firms adapt to new technologies and help improve productivity.”

The Catapult Trail will encompass the following centres:

HVM Catapult: Stand H6-622

AFRC: Stand H6-520

AMRC: Stand H6-810

MTC: Stand H17-602

High Value Manufacturing Catapult

www.hvm.catapult.org.uk

MACH-2020

Quick change gripping

Whilst widely known as a sliding head tooling specialist, Floyd Automatic Tooling will also be introducing new tool clamping technologies from Schaublin (Swiss).

To cater for manufacturers of cylindrical cutting tools, Floyd will be demonstrating the quality and diversity of the Schaublin range of products, and in particular, the new SRS range of collet clamping heads with its precision runout adjustment system that ensures repeatability within 2µm.

At MACH, Floyd will demonstrate the flexibility of the Schaublin SRS system for grinding machines using W or B type draw type collets. The SRS system is a new innovation capable of enhancing the capability for tool grinding shops.

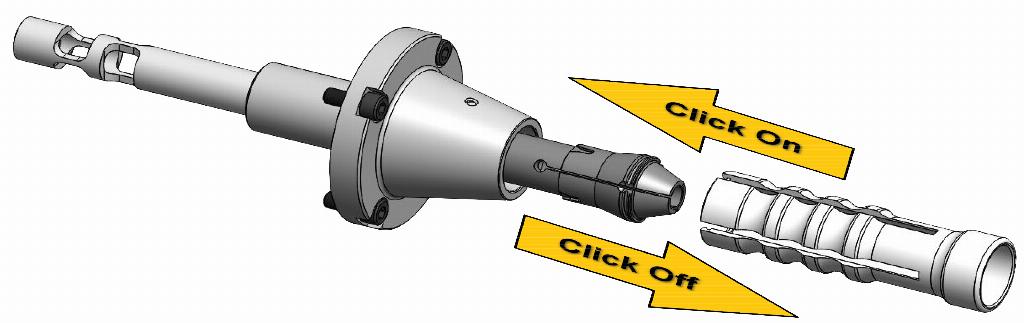

Also, on show for manufacturers in the grinding arena will be the patent pending PR25 quick change collet system. Ideal for clamping drills, end mills, reamers and other cutting tools, the PR25 is ideal for cutting tool manufacturers in a production environment where multiple collet changeovers are required.

With no on-machine changes necessary, minimal run-out, low-wear characteristics and minimal dispersion of the run-out, this high-quality solution is a great benefit for grinding shops and cutting tool manufacturers. These new clamping solutions are supported by Floyd with the complete range of Schaublin precision W, and B type collets available in the recognisable ‘orange box’.

Complementing the SRS and PR25 quick change heads, Floyd Automatic will also exhibit the Schaublin series of HSK A, HSK C and HSK E toolholders. High-quality and ultra-precise, the HSK series has been developed to ensure optimal toolholding precision when working on high-speed machining and grinding centres, transfer machines and other high-end machine tools that demand the utmost in precision with high clamping forces.

In addition, Floyd will show a diverse range of quick release clamping heads for axial draw-back collet chucks. The serrated clamping heads offer easy set-up with high rigidity levels and impressive clamping forces. For more sensitive components, precision polished clamping heads are also available for perfectly precise workpiece clamping on conventional and CNC turning centres.

For machinists needing to get a firm grip on productivity and quality when clamping components on manual and CNC turning and cylindrical grinding centres, Floyd will have a complete range of solutions available to view on its stand.

Specialist clamping and tooling solutions that range from collets, sleeves and bushes through to form tools, drilling, milling, threading, sawing and serration tools are available for every application. There will also be live demonstrations on machines provided by Star Micronics GB, Tornos Technologies, and Citizen Machinery.

Floyd Automatic Tooling

www.floydautomatic.co.uk

Stand: H20-472

MACH-2020

Added creativity to tool design

Introducing additive manufacturing to the realms of cutting tool manufacture offers design, performance and tool life benefits that in many circumstances are beyond the possibilities of traditional production methods.

For some time, Mapal has been introducing new additively manufactured product lines and at MACH 2020 this will continue with a host of new additive solutions on its stand.

By reducing the weight of PCD cutting tools through additive methods, the cutting tool manufacturer is achieving significantly higher cutting data. As 3D printed cutting tool structures can be designed and manufactured to minimise weight without compromising strength or integrity, Mapal engineers are increasingly pushing the boundaries of cutting tool design and development.

Demonstrating how Mapal uses the advantages of 3D printing at MACH, the company will showcase its new bell tools with brazed PCD inserts. Frequently used in the hydraulic and automotive sectors, bell tools are the first choice for external machining of hose connections on turbochargers where complex contour requirements must be met with precision. This means that cutting tool production must be equally precise to ensure customers can achieve their cost-effective, precision machining requirements.

To meet the needs of the end-users, Mapal has optimised the existing, conventionally manufactured bell tool by integrating selective laser melting process into its manufacturing processes. This allows the inside of the cutting tool to be modified and as a result, the tool is at least 30% lighter and tool life is increased by upwards of 40%, thanks to the enhanced vibration damping characteristics of additive manufactured tool designs.

Mapal says that customers using these additive manufactured tools are witnessing productivity improvements in the region of 50%.

Additionally, Mapal experts are using 3D printing technology to optimise the cooling channels, ensuring that cutting fluid is delivered to the cutting area via the most efficient possible route. Using selective laser melting, the new tool geometry is printed on a highly precise tool body with an HSK-63 connection. The additively manufactured tool body is subsequently machined to provide the precise platform for the PCD inserts to be brazed into place and then cut to shape using a laser.

With additively manufactured cutting tools, reliable chip breaking and optimal machining performance is a necessity. This is why Mapal will also be using the showpiece UK manufacturing event to introduce its newly developed inserts for the chip guiding stage when machining steel. When undertaking the fine machining of steel, long chips can prove detrimental to machining performance and surface finishes, especially when machining with tools that incorporate guide pads.

To prevent long chips from wrapping around the tool and creating a negative impact on surface quality, the company has introduced the new line of inserts with chip guides. The new chip guiding stage combats these problems with a new geometry design, optimised with extensive FEM analyses and practical testing, meaning chips are now broken reliably.

This prevents automated workflows and production environments from being disrupted. The chip guiding stage is compatible with all indexable inserts with AS leads.

Furthermore, the new chip guiding inserts are available with a wide variety of coatings to support the machining of a vast selection of material types. The Mapal technical engineering team will be on hand at the show to offer expertise and advice.

Mapal

www.mapal.com

Stand: H18-330

MACH-2020

Welcome to the village

The Metalforming Machinery Makers Association (MMMA) will have the biggest ever number of exhibitors at its Metalworking Village at this year’s edition of MACH.

At the time of writing, 25 five member companies are booked to exhibit on the 650m² stand. The village will demonstrate technologies, services and products across many sectors of UK manufacturing.

The Association says it has gone from strength to strength over the last two years following the implementation of a number of changes. These include an upgrade of the Association’s website, an increasing focus on social media platforms and more member benefits. Membership remains positive and trending upwards – currently the association has 44 members across a wide range of sectors.

“The MMMA Village at MACH 2020 provides an ideal opportunity for the members to show off their skills, services and technologies to show attendees across UK manufacturing. Within the village, visitors will be welcomed on each member stand, to discuss what is available, and how they can improve productivity and win more orders,” explains marketing coordinator, Bill Neal.

MMMA members exhibiting in the village include: Bruderer, Esprit Automation, Cotswold Machinery Sales, Worcester presses, Schuler, Presscare, TMA, Roemheld UK, Industrial Clutch, Kaller Gas Springs, Press Techniques, Helm Instruments, Anton Saws, Qualimach, Wilson Tool, Pressform machinery, Ortlinghaus, Decade Monitoring, Group Rhodes, Oerlikon Balzers, Voith Turbo UK, Formit, Raybould Machinery, Ross UK, and Aida SRL UK.

Other MMMA members are also exhibiting at MACH on their own stands including: KUKA Robotics; AW Precision and Decoilers & Feeders.

Metalforming Machinery Makers Association

www.mmma.org.uk

Stand: H20-637

MACH-2020