MACH 2022 exhibitor preview – Part 1

MACH 2022, the first time the show has taken place in four years, will be at the NEC, Birmingham from 4-8 April. Here is a rundown of some companies exhibiting at the show.

Drilling to the extreme

At MACH, Guhring will exhibit a complete range of threading, turning, drilling and milling tools, with many of its leading drilling lines undertaking live cutting demonstrations.

One of the standout products that will be showcased on a Grob G550 5-axis machining centre will be the RT 100T solid carbide spiral flute deep-hole drills. The range includes standard drills for drilling depths up to 15 x D, 20 x D, 25 x D, 30 x D and 40 x D with diameters available from 3mm to 14mm with an exceptional range of diameter increments.

The RT 100T demonstrates an impressive cost-performance ratio while permitting the highest cutting and feed rates – something that MACH visitors can witness with the live demonstrations. The spiral-flute deep hole drills possess a special flute geometry that is optimised for evacuating chips from deep holes. This is complemented by a coolant duct profile that maximises flow to the cutting edge and supports chip removal.

Complementing the RT 100T on the Grob G550 will be the RT100XF drilling series. Branded as ‘extreme and powerful’, the RT100XF has been developed with all tool parameters optimised to generate outstanding feed rates and metal removal rates. Created to reduce cycle times for difficult-to-machine materials and special applications in series production, the hard new drilling line is resilient to potential breakages.

With a new carbide grade developed for the RT100XF that performs a balancing act between hardness and toughness, the special structure of this carbide grade has a re-sharpening effect, so breakages that normally accelerate tool wear no longer occur. This is supplemented by the nanoFire coating system created by a specially designed pre-and post-treatment that smooths the coating and makes it more robust.

The design and geometry incorporate early double margin support that enhances coaxiality to ensure perfect bore size and roundness. This makes the RT100XF a sound choice for precision, concentricity and performance hole making.

Available in 5 x D and 7 x D with diameters from 3mm to 20mm with 0.1mm increments, the through coolant drills are ideal for the drilling of structural and case-hardened steels, free-cutting and heat-treated steels, Nimonics, titanium, Inconel and Hastalloy.

Complementing the drilling lines will be a live demonstration of the HR500 solid carbide universal reaming line, offering high cutting rates, high precision, concentricity and good surface finishes. The HPC line is suitable for finishing holes on a vast array of materials that include steels, aluminium alloys, cast materials, plastics, magnesium alloys, copper and brass.

Guhring will also have a 12mm diameter SpyroTec chamfermill on the Grob machine. The spiral five-fluted chamfer milling cutter is available with a 60, 90 or 120° angles and on the Grob machine at MACH, the 12mm diameter variant with a 90° angle will be in action.

With five different spiral angles and an uneven cutting edge, the SpyroTec – available in 6 to 20mm diameters – reduces vibration and improves surface finishes. To further enhance surface finish and provide a smooth cutting action, the SpyroTec chamfermill incorporates a positive rake angle geometry with face cutting that enables the customer to use the full cutting-edge length of the tool.

Manufactured from the finest grain carbide with a TiAlN coating, the SpyroTec prolongs tool life and enhances performance for the end-user.

As well as demonstrating an extensive range of innovative solid carbide tooling solutions, Guhring engineers will be at MACH to discuss the scope of special tooling solutions that can be designed, developed, manufactured and trialled at the Guhring facility in Birmingham.

Guhring

www.guhring.co.uk

Hall 19, Stand 210

New precision laser technology

Ingenium Integration, the sister company of UK-based tube bending machinery specialist Unison, will be showcasing the Nukon range of precision fibre laser cutting systems at MACH 2022.

Visitors to its stand will be able to see a Nukon Eco Speed Pro Line 315 4kW 2D fibre laser machine in action and discover why Ingenium Integration believes Nukon machines are the ideal choice for first-time laser users, businesses adding value to in-house manufactured products, and subcontractors requiring high-performance machines for the most demanding of laser-cutting applications.

“For such premium quality machines, Nukon fibre lasers are incredibly accessible,” comments Ingenium Integration sales manager, Steve Haddrell. “Several models also have an extremely compact footprint, making them well-suited to production environments where floorspace is at a premium.

“Additionally, companies buying a Nukon fibre laser cutting system from Ingenium can expect to receive the same uncompromising levels of service and support as enjoyed by users of Unison tube bending machines.”

The Nukon fibre laser range includes 2D, 3D (5-axis) and laser tube cutting machines. High specification standard features include: nLIGHT fibre lasers with adaptive beam optimisation, and Lantek Expert software – one of the most advanced CAD/CAM nesting software packages on the market today.

Available in a range of power options and sheet sizes, Nukon’s 2D fibre laser machines combine high performance with high efficiency.

The Nukon range of 3D, 5-axis machines has been developed for the most challenging applications, such as precision-cutting tubes, pipes and intricate profiles in a wide variety of materials, as well as R&D work.

While Nukon laser tube cutting machines include pipe and profile cutting models, additionally the ‘Vento Flex’, laser cutter is a highly versatile machine that combines all three as well as flat sheet metal.

To assist customers in maximising the productivity and efficiency of their laser-cutting operations, Ingenium Integration also offers Nukon’s range of fully automated loading and unloading solutions.

Before being appointed as Nukon’s exclusive UK and Ireland distributor in 2021, Ingenium spent time searching the market for a range of high-quality, accessible laser-cutting technologies that would be of significant interest to manufacturers.

Mr Haddrell concludes: “Short of building our own laser cutting machines in-house, our challenge was to find an established product range that mirrored the uncompromising levels of accuracy, reliability, build quality and support that are synonymous with the Unison name. We believe we have found such a product range in Nukon.”

Ingenium Integration

www.ingeniumintegration.com

Hall 6, Stand 723

MMMA Metalworking Village roundup

Occupying 650m² of exhibition space, the Metalforming Machinery Makers Association’s Metalworking Village will have its largest presence ever at MACH 2022.

“The MMMA hosting its specialist metalworking exhibition within MACH 2022 provides a fantastic opportunity for our members to show off their skills, services, and technologies to visitors across manufacturing UK,” enthuses MMMA marketing co-ordinator Bill Neal.

“Within the Village, visitors will be welcomed on each member stand to see and discuss the technology on offer with a view to improving productivity, winning new business and increasing profitability.”

Members exhibiting include: Bruderer UK, Esprit Automation, Cotswold Machinery Sales, Worcester Presses, Schuler UK, TMA, Roemheld UK, Industrial Clutch Parts, Kaller Gas Springs, Press Techniques, Helm Instruments, Qualimach, Pressform Machinery, Decade Monitoring, Group Rhodes, Formit, Raybould Machine Tools, Aida SRL UK. OSA Systems. Cidan Machinery,UK, Midland Power Press Services, Orlikon-Balzers and Ortlinghaus.

Many members will be showcasing brand new technology and services during the week. A selection is listed below:

Qualimach represents the Faccin Group in the UK which has more than 30,000 units installed around the world. With three highly recognised brands in the metal forming industry – Faccin, Boldrini and Roundo, the company is a leader in the design and fabrication of innovative machines for rolling and bending metal sheets and profiles.

The Group throughout these brands, offers a wide portfolio of plate rolls, section rolls, dished head lines and special machines globally serving industries such as oil and gas, wind energy (towers, foundations, flanges and door frames), transportation and earth moving, pressure vessels, tube and pipeline, shipbuilding, metal fabrication and others.

Decade Monitoring Solutions is a UK company offering off-the-shelf products and bespoke systems to the manufacturing industry. Its specialities include automation and load monitoring systems for power presses, process monitoring and control in assembly machines and production recording systems.

Its cloud enabled 180 series will be revealed along with DLM, 160, 170 and Mars products. These products cover everything from peak load protection, curve monitoring and downtime recording to complete OEE systems.

Formed in 1968, Bruderer UK has established a reputation of excellence in the sphere of high speed precision stamping. From its Luton location, the company supplies its customer base with authentic spare parts and service support from its UK-based team of factory trained service personnel.

At MACH Bruderer will be exhibiting a fully operation stamping production line, featuring the latest press technology and ancillary equipment. Also on show will be a range of press servo feeders, de-coiling and rewinding equipment, tooling components, die handling solutions, press and tool monitoring protection systems, vision inspection systems, roller and spray lubrication equipment, products marking and multi-slide machines.

Worcester Presses offers a combination of mechanical Chin Fong and Worcester bench press ranges, hydraulic presses, Tomac coil handling equipment and press transfer systems. It can provide complete turnkey solutions which can incorporate guarding, load monitoring, quick die change systems (QDC) and additional ancillary equipment to increase productivity. At the show Worcester Presses will be showcasing a Chin Fong OCP-110 ton press.

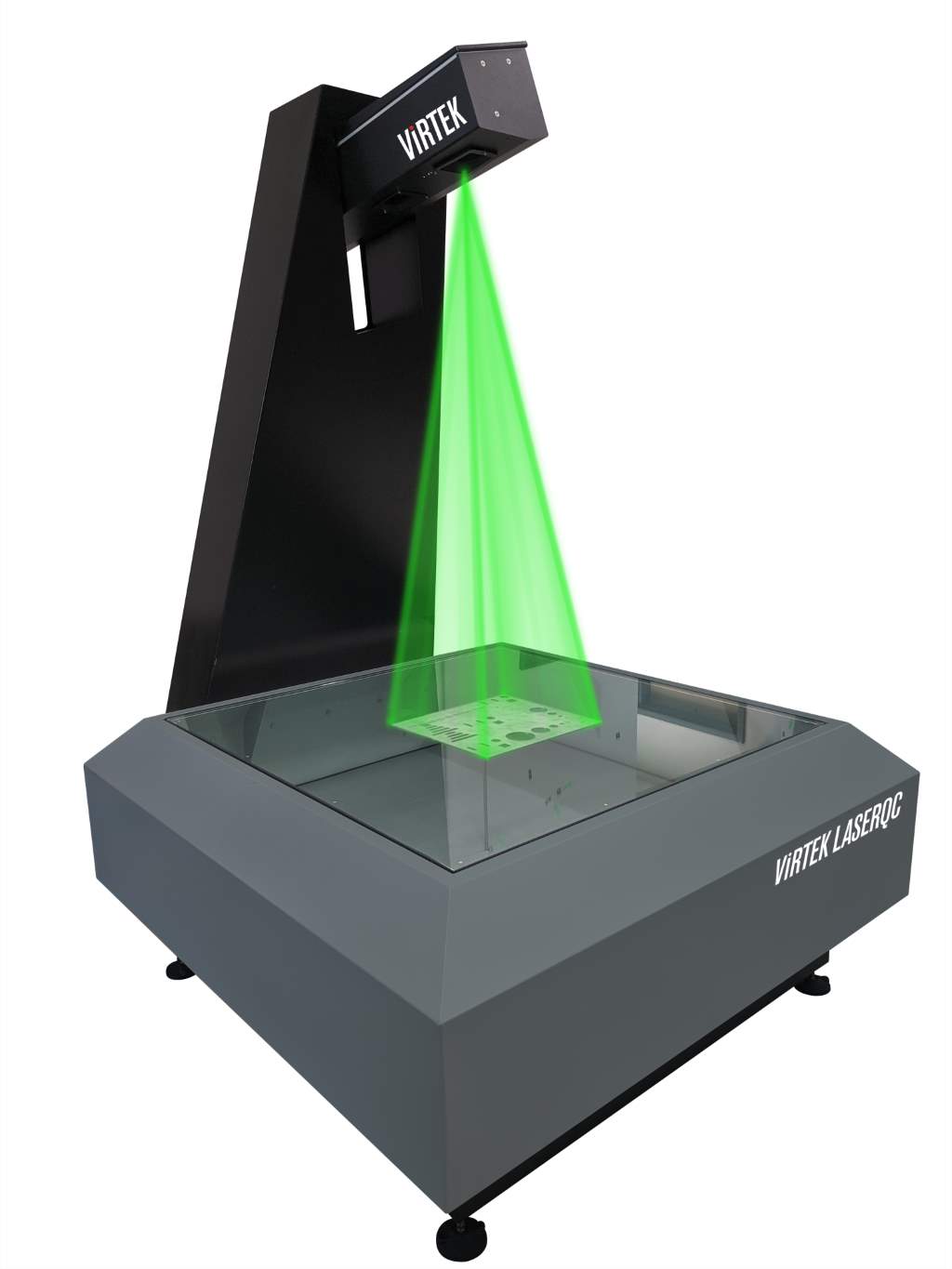

Wakefield-based Press-Form Machinery is the official UK agent and service partner for Virtek, a market leader in laser projection and inspection systems. Virtek’s LaserQC system is a proven solution for inspecting parts from pressed, punched and laser cut operations with over 1,500 units already in use throughout the world and the UK. The company claims it is the world’s first fully automatic, self-calibrating high-speed laser inspection system.

Capturing more than 500 data points per second, the LaserQC is accurate to within 0.05mm and verifies system calibration before each scan to ensure repeatable accuracy. By pinpointing errors immediately on the shopfloor, scrap and rework is reduced and profitability increased.

On display from Industrial Clutch Parts (ICP) will be the range of Nexen linear and rotary roller pinion products for precision positioning requirements. ICP offers both versions of Nexen's ring drive indexer systems based on innovative roller pinion technology.

Both the compact ring drive (CRD) and precision ring drive (PRD) enhance rotary positioning operations by providing high positional accuracy, high rigidity and acceleration, low maintenance and long life service.

Workholding expert Roemheld UK will be showing a selection of new double-acting arch clamps for securing dies or moulds to the bed or ram of a die casting, injection moulding or other type of press. Intended for holding tools with flat edges safely, the compact clamps exert a force ranging from 30 to 450kN.

They consist of a hydraulic block cylinder and piston. Due to the internal design, the horizontally-acting force is translated into an almost vertical clamping action. An integrated mechanical locking bolt is provided to maintain the clamps in position, particularly on the ram, in the event of a drop in hydraulic pressure.

MMMA

www.mmma.org.uk

Adding to the union

Rainford Precision will be focusing on its micro-machining expertise at the show.

The Cheshire-based company will introduce new additions to its extensive product portfolio with particular emphasis on a show debut for its new V-Series of small end mills from Union Tool.

The new V-Series of square, radius and ball-nose end mills is a complete line-up of high-quality precision end mills with 3mm diameter shanks to cater for machine shops undertaking the challenges of small part machining.

With the shanks ground to an h4 finish on specialist grinding machines, customers can be assured of the quality of this latest Union Tool series. This level of precision also improves machining performance when undertaking high-speed machining with high-end collets and shrink fit systems.

The V-Series is offered in three variants, the VHLS, VHLRS and the VHSLB which identifies the square, radius and ball-nosed options. The tools have been developed with Union Tool’s Hardmax coating technology to provide a productive combination of hardness, durability and heat resistance for machining hard materials from 40HRc to around 65HRc.

This hard-wearing coating makes the V-Series suitable for cutting a wide range of materials from carbon, alloy and pre-hardened steels through to hard steel, heat resistant alloys and more.

Manufactured from a super micro-grain carbide with a 30° helix, flat land and optimised geometry that demonstrates extreme resilience when machining challenging materials with very small tools, the V-Series is a sound choice for machining with tool diameters as small as 0.1mm.

As part of the range that will make a UK exhibition debut at MACH 2022, the VHLS 2-flute range of long neck square end tools is available in diameters of 0.1 to 0.6mm in 0.1mm increments with 0.8, 1, 1.5 and 2mm diameter tools completing the line-up.

The effective cutting length varies from 0.3mm to 6mm depending upon the chosen diameter, but most of the series is offered with a choice of cut length geometries to maximise the rigidity and strength of the micro end mills according to application. All diameters are provided with a 38mm overall length and 3mm shank diameter with a necked diameter and 16° tapered angle for additional clearance when machining intricate features and surfaces.

Alongside the VHLS square end tools is the new VHLRS short shank long neck radius range of two-flute end mills. Also manufactured from a standardised 3mm shank with 38mm overall length, the VHLRS is available from 0.2mm diameter to 2mm with necked and tapered shanks for additional clearance.

The 0.2 and 0.3mm diameter end mills are provided with a 0.05mm radius whereas the 0.4, 0.5 and 0.6mm tools are offered with a 0.05 or 0.1mm corner radius option with a choice of flute lengths to suit specific applications. The 0.8, 1, 1.5 and 2mm diameter tools provide a choice of effective flute lengths and corner radii from 0.05 to 0.2mm to meet the specific demands of the end user.

For extremely small profiling applications and parts that demand the utmost precision, the two-flute VHSLB range of ball-nosed tools is available. This impressive high-precision range of end mills is available with a ball-nose from as small as R0.05mm and extending through 0.1, 0.15, 0.2, 0.25, 0.3, 0.4, 0.5, 0.75, 1, and 1.5mm.

Except for the smallest R0.05 tool that has an effective flute length of 0.3mm, every tool diameter in the VHSLB range is offered with a wide variety of effective cutting lengths to provide complete stability, strength and rigidity for the specific task at hand.

The quality and performance of the new V-Series is matched by the other high-quality ranges available from Rainford Precision and Union Tool. Visitors to the company’s stand will also have the opportunity to view a wide selection of cutting tool solutions from well-known brands such as, Louis Bélet, Delmeco, Gloor, Hobe, Osawa, DTS, Iwata and Atom.

Experts from Rainford Precision will also be on hand to discuss ultra-precise machining solutions from Kern, laser micromachining from Lasea as well as micro waterjet machining technology from Finepart.

Rainford Precision

www.rainfordprecision.com

Hall 20, Stand 573