Mach machines take-off at helicopter maker

Mach Machine Tools has supplied, Hill Helicopters – a vertically-integrated manufacturer of luxury private helicopters – with two new manual machines.

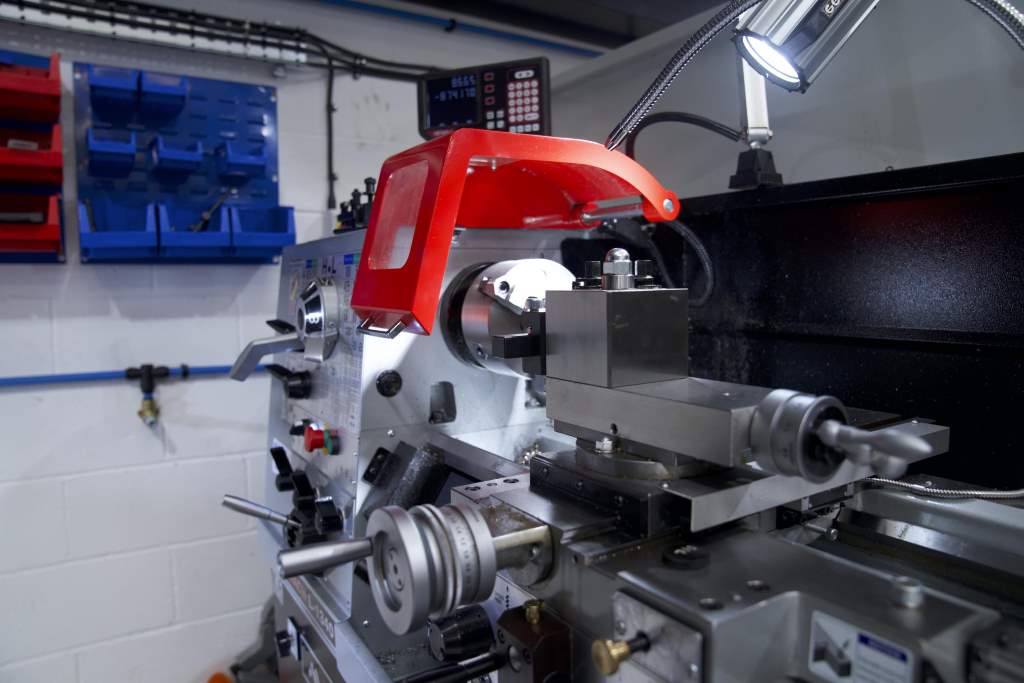

The machines, comprising a Mach VS-1SP (Super Precision) vertical turret-type mill and a Mach L-1340 lathe, were installed at Hill’s modern 5,250ft² Development Centre in Rugeley, Staffordshire in May and October 2022, respectively.

The investment in both models was made to increase the machining capacity and capabilities of the company’s, newly-established, toolroom and, by doing so, help free-up its advanced, production-led CNC machine tools from having to be available to undertake routine and less complex and critical machining operations.

Although only recently acquired, the two machines have already proved their worth and are an important part of the company’s overall in-house machining resource.

The two Mach machines, along with other manual equipment, have been installed in a specially-designated and demarcated toolroom – positioned within the company’s impressive machine shop facility.

The toolroom plays a crucial supporting role in helping the company achieve its daily production targets which, at present, are focused on designing, developing and machining high-precision prototypes and pre-production parts (and their attendant machining processes), for its HX 50 (private), and HC 50 (commercial), helicopter platforms.

To date, the two Mach machines have mainly been utilised for machining one-offs and small batch series as well as machining intricate features (i.e. thread forms on shafts) on specific parts. The machines are also being used to manufacture a range of jigs and fixtures which, when completed, are transferred over to the production-orientated CNC machines in the machine shop.

Mark Webb, Hill Helicopter’s lead production engineer explains: “The Mach machines are accurate, fast, flexible and reliable and are helping us improve our productivity and process efficiencies.

“Our toolroom facility acts like a business within a business. It exists to serve and support our wider machine shop needs and takes pressure off our production CNC machines which, to meet our tight deadlines, are always in high demand.”

The acquisition of the two Mach machines followed a chance meeting earlier in the year between Mark Webb and representatives of Mach Machine Tools at the MACH 2022 exhibition in Birmingham.

Mr Webb continues: “We attended the MACH show primarily to look at acquiring a range of ancillary machine shop equipment like wash tanks, welding kit, rumblers and polishers etc., for our machine shop. During the visit we came across the company’s stand and there, in plain view, were a number of manual machines that, I believed, could do an important job for us.

“I met Dave Andrew from Mach Machine Tools to discuss our requirements and, after agreeing the scope and scale of the investment and finalising all the details, ordered a manual mill and a manual lathe there and then.”

With a VS-1 SP already in stock and available for immediate delivery, the decision was made by Mach to loan Hill Helicopters an ex-demo L-1340 lathe from its showroom until a new lathe become available.

“We appreciated Mach’s flexible and proactive approach that would enable the mill and lathe to be delivered to us at the same time,” Mr Webb recalls.

Although Mach Machine Tools’ involvement with Hill Helicopters is currently limited to the supply of one manual mill and one manual lathe, this could change, quite dramatically, in the future.

The planned move in 2024 to a brand new, 330,000ft² manufacturing facility in Stoke, to enable the company to ramp up production to meet its year 1 and year 2 targets, which translate to building and delivering 250 and 500 helicopters, respectively, to customers around the world, presents opportunities for the relationship between both companies to grow.

“We will be increasing our headcount quite considerably in the years to come (from 40 to 400+) and, to help address future skills shortage issues and problems recruiting talented staff, will create an Apprentice Training School at the new facility,” says Mr Webb.

“To ensure new recruits learn basic and foundation level engineering and machining skills and competencies, it is our intention to invest in a number of additional manual machines to train apprentices ‘the Hill way’.”

This is another example of the company controlling the means of production, of its commitment to vertical integration and of developing and bringing, in-house, as many manufacturing technologies and processes as possible.

The VS-1 SP is a compact, high-precision turret-type milling machine with a 1,245mm x 229mm worktable, X- and Y-axis travels of 850mm and 305mm respectively, an infinitely variable spindle (420 – 5,000rpm) and a 2-axis DRO.

The L-1340 is a rigidly-designed manual lathe equipped with a 2.2kW/2,570rpm spindle, a quick-change tool post and a tailstock. The machine has a 171mm centre height and 1000mm distance between centres.

Mach Machine Tools

www.machmt.co.uk