Manufacturing in the midst of Brexit

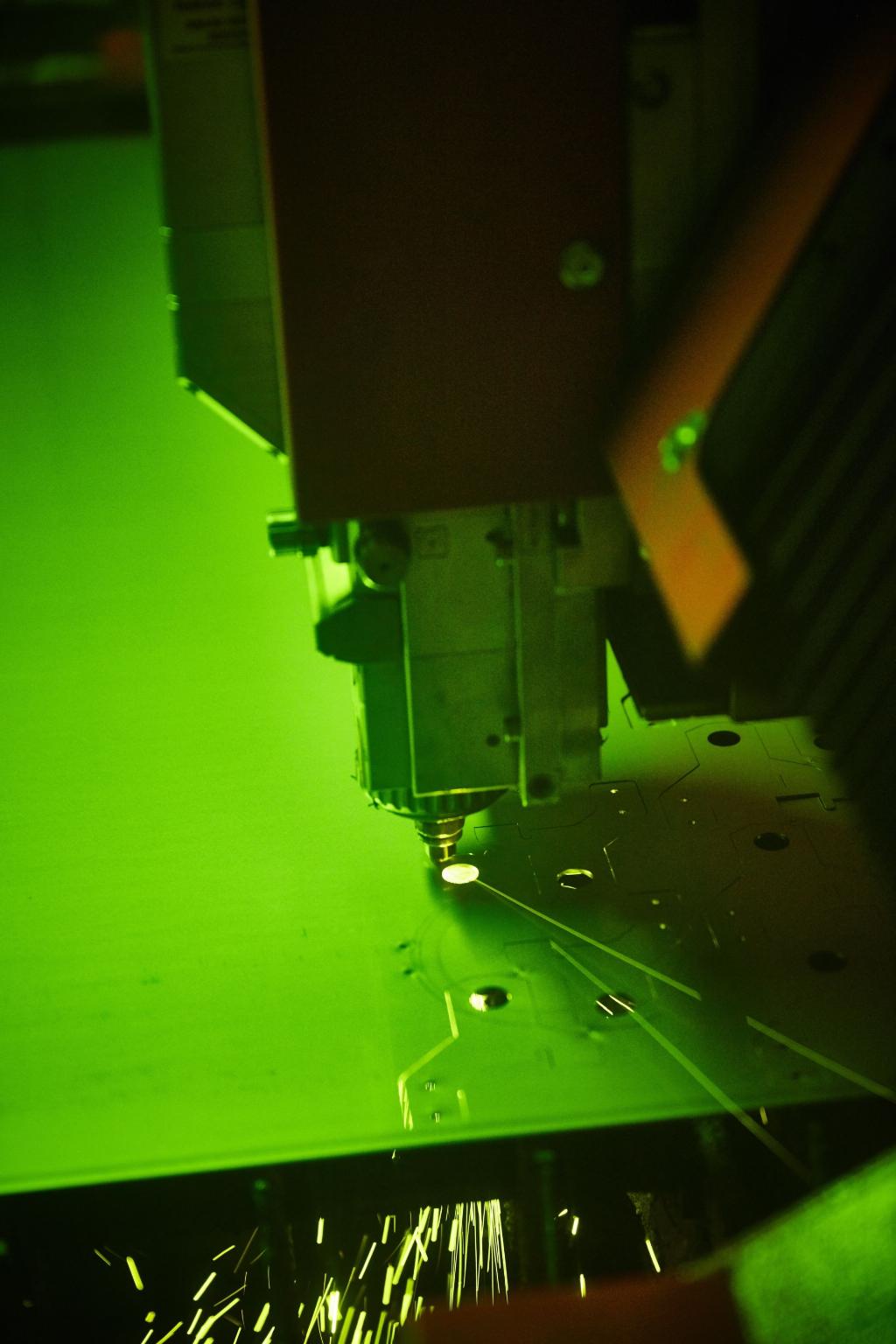

Charles Corner, director of full-service sheet metalwork manufacturer, Malton Laser, discusses his thoughts on what Brexit holds for the manufacturing industry.

Brexit has caused a state of uncertainty for a number of industries; the future for some UK businesses is unclear with many unsure on how to prepare for the upcoming changes. Charles Corner, director of full-service sheet metalwork manufacturer, Malton Laser, discusses his thoughts on what Brexit holds for the manufacturing industry.

When the Brexit referendum came into question I personally believed remaining in the EU would be the best decision for the UK, so the result was definitely a shock. Our democracy had spoken, and the only option was to look to the future and prepare the best we could.

Unprecedented growth put Malton Laser in a very strong position ahead of the referendum result, and I had also recently invested in new technology and automation with the addition of a revolutionary Panasonic robotic welder. This allowed the company to enhance its fabrication services, offering the latest in technology with the new automation system, a great new string to our bow when it comes to quick-turnaround projects.

The two-station Panasonic Tawers MAG 1600WG Welding Robot System, has increased our welding capacity by up to 30% and has the ability to weld four times faster than our previous methods.

This investment was incredibly timely, with the devaluing of the pound we received an influx of orders – I know other manufacturers experienced this surge too as the economic change caused exports to grow. It’s certainly an interesting position to be in!

While we don’t export products to Europe, our customers do and this is where we come in – manufacturing the necessary components to create the finished goods. Many of our customers are flourishing as Europe is buying more products from the UK, possibly in the light of the uncertainty we are all experiencing to secure trade deals and build long-term relationships with companies they trust to provide a reliable service.

At Malton Laser, I have strived to implement a low manpower, high productivity ethos to boost output and efficiency. Automation is a huge part of this, not only does it deliver more precise, accurate and uniform output, but it also reduces the risks of human error, untimely work and simple mistakes that can result in unplanned costs for a manufacturer.

I strongly believe this work ethic has prepared us in the best way possible for what Brexit has in store. We can efficiently plan ahead for almost any work that comes our way as automation works steadily, maintaining a speed and reliably producing, cutting or finishing goods at a predicted rate. Alongside this, the machinery can work for long hours without human error, finger marks, injury, sick days or holiday, while allowing us to easily determine how much product will be created, cut or finished by looking at the machine’s statistics.

Knowing how quickly a machine can produce finished goods is very much a key benefit for both manufacturers and customers, as it is much easier to work to specific time frames when you know how quickly you can turnaround an order.

As automation is used for a number of processes throughout the metalwork industry, in the form of laser cutting, pressing and powder coating, it could be considered that robots are slowly taking over and replacing skilled workers. However, we like to think of it as an opportunity. Manufacturers that are able to achieve the perfect balance of skilled staff versus automation will have the opportunity to really grow their business, whilst future-proofing it in the midst of Brexit.

With Brexit looming, the manufacturing industry is under additional pressure to stay ahead of the times and not get left behind as other industries evolve.

But what does all this mean for manufacturers? It means a great deal of change. It’s more important than ever to ensure your business is adaptable and open to transforming to mould to circumstances which may require a different approach.

The Confederation of British Industry recently stated that parts of British manufacturing risk becoming extinct unless the government stops talking politics and starts taking action to ensure real, frictionless trade post-Brexit.

I still remain very optimistic. Banks are in a better position to fund companies’ aspirations, if you choose to be apprehensive and not invest – you may regret this in the long run.

This means it’s imperative that businesses start making adaptations now. Strive to build lasting relationships with clients, go the extra mile to show customers you are fully matching their requirements and have industry-leading technology on site to carry out all aspects of work they require, or that you have a reliable outsource to utilise.

Technology is at the heart of Malton Laser and I have firmly placed my confidence in new technological developments and advancements. Despite what others may say, I really feel this puts us ahead of the field when it comes to evolving with the times, it has certainly helped us overcome previous challenges. Overall, I think Brexit should encourage manufacturers to keep an open mind and seize opportunities that come their way, ensure your processes are efficient and you are always prepared for a decline of influx in capacity.

Malton Laser