Lifesaving metrology

Ejection seat specialist Martin-Baker has to manufacture components to the highest aerospace industry standards. In this article PES hears more about its use of Mitutoyo inspection and metrology equipment.

Nothing in the manufacturing industry epitomises human safety more than the name Martin-Baker. Founded in 1929 as an aircraft manufacturer, the company evolved to producing aviation ejector seats.

As the world's foremost manufacturer of aviation ejection seats, it has saved more than 7,578 lives to date with 19 pilots saved in 2018 alone so far.

Since 1946, Martin-Baker has delivered more than 85,000 seats to 91 nations with more than 16,000 seats currently in service in 78 countries across 51 aircraft types. For more than 25 years, the company has been measuring and controlling the quality of its seats and the critical life-saving components with the help of metrology expert Mitutoyo.

Martin-Baker currently produces more than 40 seats each month plus a complete variety of components for the regulatory maintenance and repair cycle of existing seats in service.

It produces everything from spares for seats dating back to 1949 through to more than 700 parts for the latest F-35 fighter. This means the company currently has 25,000 live components and more than 50,000 parts on its inventory list.

Components are manufactured on 25 CNC machine tools at its 800-employee manufacturing site, which also includes a four machine 72 pallet DMG cell that runs 24 hours a day; 364 days a year.

Ensuring that components conform to its exacting standards the company has an inspection department with 55 staff that relies heavily on inspection equipment from Mitutoyo. Inspection manager, Darren Smith says: "Martin-Baker has had a long association with Mitutoyo, using hand tools like micrometers, vernier calipers and height gauges as well as CMMs for more than 30 years. We now have five Mitutoyo CMMs, three SurfTest machines, a Contracer, two training kits and the Mitutoyo MeasurLink system for Statistical Process Control (SPC). We also have over 300 Mitutoyo hand tools and gauges on-site.

“The equipment and services Mitutoyo provides gives us a really strong platform to meet the challenges we face. We have been utilising Mitutoyo packages across the board. It’s not just about the hardware, we also use the MeasurLink software that helps us with our measurement system analysis program and this allows us to gauge our R&R and SPC. We also use Mitutoyo training packages such as on-site training and we have even bought training kits and equipment to support our own training.”

Mr Smith continues: “We have an ever-increasing demand put upon us by our design department, so over the last few years, they have changed the principles of how we tolerance our drawings. We have adopted gauge and dimensional tolerancing (GD&T) and the demands placed upon the business has required us to have more applicable equipment to actually meet these demands. We’ve looked in the last five years at investing in standardised equipment across the board that meets all the demands our design team give us.”

The equipment

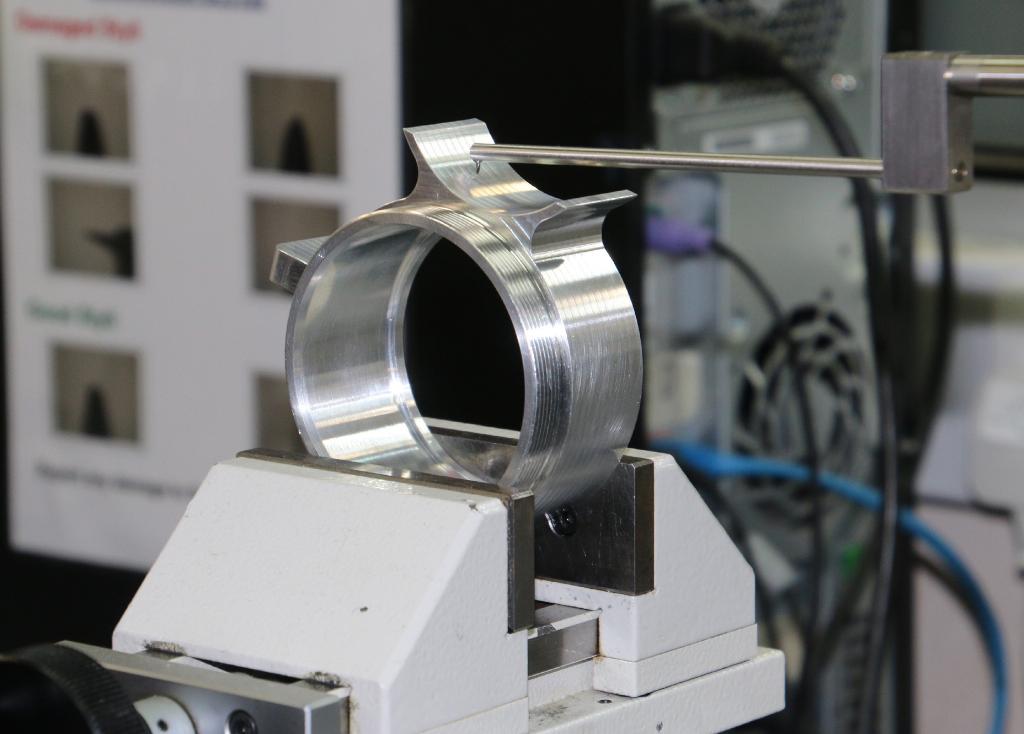

Martin-Baker has two Crysta Apex 9206 CMMs in its inspection department with another checking components at goods-in, whilst a smaller Crysta Apex 9106 CMM sits alongside the DMG Mori production cell on the shopfloor. At its Uxbridge facility in West London it also has two CV3200 Contracer form measurement machines for inspecting contours and profiles as well as three SurfTest Extreme SV-3000 CNC surface roughness measuring machines.

What makes this technology and configuration genuinely impressive is the investment in peripheral equipment and software that works in complete synergy with the hardware. Each of the CMMs has a standardised and comprehensive rack of probes and this includes the SP25 analogue scanning probe with the scanning software module that is part of the Mitutoyo M-COSMOS 3 software suite.

The SP25 probe provides continuous contact with the workpiece and this improves the inspection cycle times whilst giving 100% inspection on free-form shapes. The circularity and concentricity of holes and bores is guaranteed with the constant probe contact that multiplies the measuring points, giving the customer complete confidence in its inspection processes.

Software synergy

The SP25 analogue scanning technology works in complete synergy with the CAT 1000PS surface analysis software. This CAD modelling suite enables Martin-Baker to rapidly load its CAD models direct to the CMM and overlay them with the path of the inspection probe.

By scanning components directly from CAD models, the company has standardised its procedures, instilled a measurement process ethic among staff and also slashed metrology programming times. By selecting the most efficient probe paths and cycle routes, the CAT 1000PS technology has enabled Martin-Baker to build a part library and continually optimise the probing cycles.

Mitutoyo’s technical sales representative Chris Pullen commenting upon the software says: “The M-Cosmos 3 software suite that incorporates the CAT 1000PS technology provides a uniform platform for measurement at Martin-Baker whilst improving inspection cycle times and throughput. Furthermore, the ability to store a complete library of optimised programs creates a platform for historical and uniform inspection. More recently, it has invested in the latest edition of the Mitutoyo MeasurLink software for SPC.

“This software offers complete PPK and CPK reports with charts and histograms providing comprehensive reporting that enables us to measure, monitor and review not only current production dimensional values, but also measure values against historically recorded data. This data can be recorded on every feature of every part produced and this is the level of uniform conformity that the company is investing in.”

Furthermore Martin-Baker has recently added the Mitutoyo U-Wave wireless technology that enables equipment from hand tools such as micrometers and vernier callipers to be connected wirelessly via Bluetooth to the M-Cosmos 3 software to automatically generate uniform inspection reports on components. The company can select the measurement parameters for the report and the respective parts and from this shopfloor staff can instantly generate inspection reports.

This huge swathe of data is all provided on a ‘live’ platform that can be overseen by the inspection manager through a ‘process analyser cell’.

Mr Smith confirms: “The facility to view inspection data of hundreds of parts and thousands of measurement parameters on a live basis enables us to monitor our SPC values against production and identify any deviation in production data. We can feed this measurement data to the production department and identify issues on particular machines, components or processes within a cell.”

Calibrate to accumulate

Mitutoyo is one of the few metrology specialists that has its own UKAS certified laboratory in the UK. This enables the Andover inspection specialist to calibrate its own inspection equipment for its customers to a certified standard in the UK. All equipment supplied to Martin-Baker passes through the Mitutoyo laboratory in Coventry to ensure equipment meets internationally accredited standards.

Mr Pullen states: “We are one of the very few OEMs that can offer this service in the UK and this is also supported by our comprehensive training packages. We have a team of Mitutoyo trainers that can deliver City & Guilds accredited training through our bespoke programmes. Available to clients on-site or at Mitutoyo, we recently trained more than 40 Martin-Baker staff on-site, giving them City & Guilds qualifications in both Gauge and Dimensional Tolerancing (GD&T) and also Metrology Fundamentals.

Concluding upon the longstanding partnership with Mitutoyo and the evolution of the Martin-Baker business, Mr Smith says: “Over time you have an evolution of production techniques, material technology, machining capabilities, design and manufacturing methods and much more.

“To meet all of these demands, we have to not only look at what we need to do today but also anticipate and plan for future generation programs. The Mitutoyo service and support encompasses everything from hand tools and gauges through to CNC inspection machines, the supporting software and reporting technology, calibration, staff training and more. This ‘all encompassing’ service gives us complete confidence that Mitutoyo will not only meets our demands today, but also in the future.”

Mitutoyo www.mitutoyo.co.uk

Martin-Baker www.martin-baker.com