New kid on the block wins over precision subcontractor

When Mark Chesher joined Derby-based fabrication specialist MCE Engineering in November 2020, his brief was clear – to raise the profile of the machining side of the business. With that objective in mind, his first investment was a new 4-axis vertical machining centre from a brand you probably won’t be too familiar with – Pinnacle Machine Tools. Dave Tudor reports.

Formed in 1996, MCE Engineering is no stranger to working with high profile customers. Indeed, its client base includes household names such as Rolls-Royce Submarines, Bombardier, Boots, Premier Foods United Biscuits and McVities – but it’s equally at home dealing with smaller businesses to assist with their requirements spanning prototyping to volume production.

Historically, fabrication is at the heart of MCE’s proven pedigree and that’s reflected in the range of services the company offers which includes press braking, guillotine work, box and pan folding, plasma and oxy/propane cutting and more. Welding is also a core skill – TIG, MIG and MMA (manual metal arc).

MCE undertakes a wide variety of work, but has specific expertise in the materials handling/production support and food processing equipment sectors. This includes not only component parts but also sub-assemblies for conveyors, wrapping systems, vibratory feeding equipment and confectionery guide systems. The company is an approved supplier to the nuclear and rail industries.

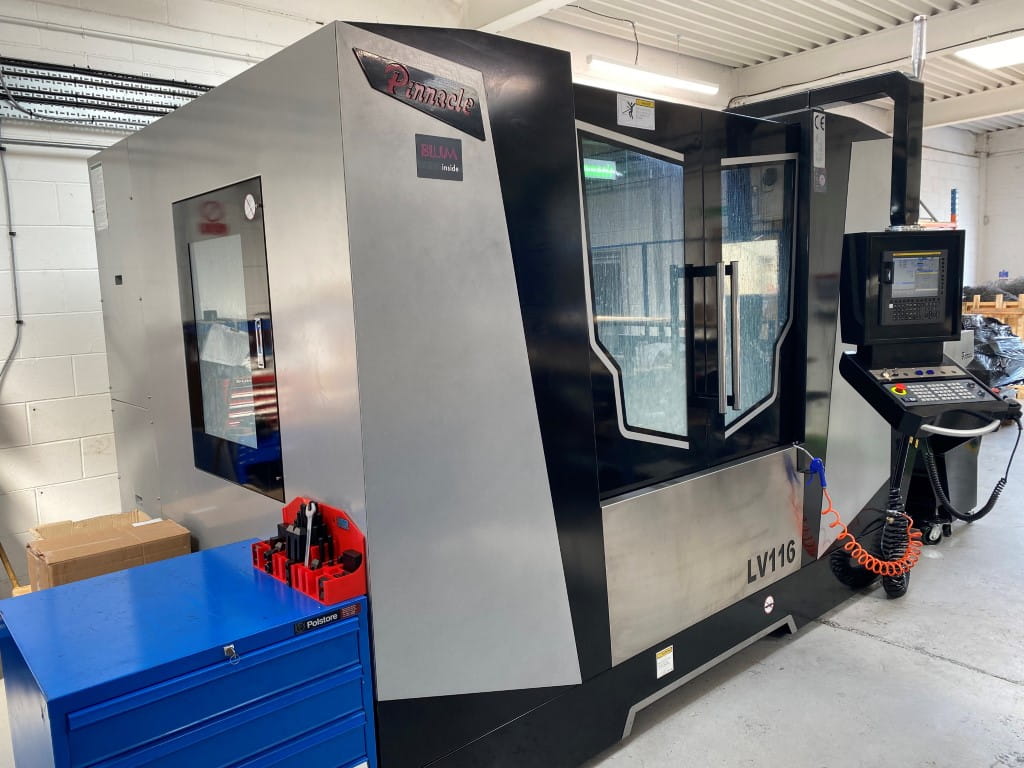

At MCE, machining traditionally been a complementary process to the company’s more established fabrication credentials but that looks set to change with the recent purchase of its first CNC machine - a Pinnacle LV116 3-axis VMC in May. For a business that could previously only offer manual/NC machining, this represents a significant investment. More importantly, it signifies a step change in direction in terms of the services the company can offer its customers.

Another significant development (and investment) for MCE, following advice from Pinnacle Machine Tools’ sales manager Alan Robinson, was to invest in Autodesk Fusion 360 cloud-based 3D modelling CAD/CAM software. Whilst it is absolutely possible to program the Pinnacle LV116, via its Fanuc 0i-MF and 10.4 inch colour TFT screen directly at the machine, MCE has opted to program remotely from the office.

“We work closely with Autodesk,” says Pinnacle managing director, Neil Gallant, “so we were able to develop a post-processor specifically for the LV116 ready for use once the machine was installed. This enables MCE to fully simulate parts and programs before any machining takes place. It has made a huge difference to their set-up times and means that quotations to customers are far more accurate.”

Rewinding a little, MCE’s managing director Pete Murray approached Mark Chesher last year with a view to raising the profile of the machining side of MCE’s business: “The brief from Pete was actually multi-faceted,” Mark Chesher recalls.

“Firstly, he needed someone to totally modernise and expand the machine shop, bring in new equipment, develop new manufacturing methods and ultimately win new business by diversifying into new markets. The second aspect however was to head up business development across the entire company which will be more of a longer-term objective. Needless to say, the challenge really appealed to me and I started in November 2020.

“At the moment, the fabrication and machine shops are in separate buildings, but plans are in place to merge the two functions under one roof which will help streamline operations, make us more efficient and really drive home the fact that we offer a complete service – from design, fabrication and welding through to machining, grinding and sub-assembly work – in a wide variety of materials.”

The data doesn’t lie

MCE’s relationship with Pinnacle began quite soon after Mark Chesher joined the company. He spent the first couple of months evaluating the type of machining work MCE was winning – and losing – and realised pretty quickly that to compete in the marketplace, the business would have to invest in CNC machines.

“I recall our first meeting with MCE,” Neil Gallant adds. “Mark visited us at our facility in Warrington and met with my colleague Alan Robinson. We looked at a number of components MCE were machining manually, took those cycle times and costs, and then, via simulation, replicated the same parts machined on a VMC.

“The difference was staggering. One potential order in particular, that was being estimated by MCE to take 20 hours to produce, could be completed in less than 8 hours on a Pinnacle VMC – and that was being conservative. We didn’t want to make any false promises to Mark or fail to live up to our claims regarding cycle times. At the end of the day he had to present this to management so we erred on the side of caution with our forecasts and predictions.”

“This proved what I already knew,” Mr Chesher affirms. “With machining, MCE were losing out on potential business because our lead-times were not competitive due to cycle times being too long. This reinforced my justification case to the management even more strongly.

“I have to say Alan at Pinnacle was so helpful during these early stages of the project and that remains the case today. The fantastic service levels are definitely one of the main reasons I chose to make the investment with Pinnacle.”

People buy from people

Granted there are better known machine tool brands that Mr Chesher could have chosen for his first CNC investment, but then there’s much more to buying a machine than just the equipment itself – it’s all about the total package. And when all’s said and done, people buy from people.

For the record, Pinnacle Machine Tools Ltd is the exclusive UK distribution partner for the Pinnacle Machine Tool Co, a family-owned business based in Taiwan. The parent company has been manufacturing high-quality machine tools since 1976 and has sold more than 40,000 machine tools worldwide.

“I’ve known Alan Robinson for 20 years now and trust and respect his vast knowledge of the machine tool market,” Mr Chesher says. “He’s worked for a number of leading companies during his career but he really rates Pinnacle machines. If he didn’t believe in them, he wouldn’t sell them. They’re incredibly well-built and represent excellent value for money – and we’ve had exemplary service along the way from both Alan and Neil. I’d have no hesitation recommending them.”

Pinnacle is part of the Neutronic Technologies Group – one of the largest brand independent repairers of industrial machinery and automation systems in the UK and the Warrington facility is not only home to Pinnacle’s machine tool showroom; it’s also where Neutronic is located. There’s an obvious natural synergy between the two group companies and they work closely together on machine sales, spares, support and service. This was also something that appealed to Mark Chesher when drawing up his shortlist.

Bang for buck

So let’s take a closer look at the Pinnacle LV116. MCE Engineering machines a lot of stainless steel so rigidity and power were prerequisites on the specification. This is a mid-sized VMC with linear X, Y, Z guideways, 1,160 x 600mm bed and a high torque 10,000rpm direct drive spindle with through coolant. The machine is available with Siemens, Fanuc and Heidenhain CNC. MCE opted for Fanuc.

Optional extras specified by MCE included a Blum probe for in-machine component and tool length measurement, a spindle probe, a Detron 4th axis rotary table and a 24 piece tooling package.

“Pinnacle is a relatively new brand to the UK but very well-known globally,” Mr Gallant affirms. “We offer a full range of machines with some really innovative features. For example with our 5-axis machines, we have two options: a traditional trunnion style architecture or alternatively our BX range which feature an embedded C-axis and a swinging B-axis where the spindle head will actually rotate 120° in both directions. If you think about that, with the embedded rotary table, that’s a VMC, a 5-axis and an HMC all in one machine. We have a BX model in our showroom.”

Neil Gallant is keen to sing the praises and virtues of Pinnacle machines in the marketplace: “People will think that because they’re Taiwanese machines, they can’t compete with the big players in the market but I would categorically disagree,” he asserts.

“My colleague Alan Robinson has worked with a number of premier league machine tool manufacturers but when he joined us he was genuinely astounded by the build quality, rigidity, accuracy and high standard of craftsmanship that goes into every Pinnacle machine.

“We’re simply asking prospective customers to give us a try. Pinnacle machines are great value but no compromises have been made. If anything, they’re over-engineered. You get a lot of machine for the money.”

MCE Engineering

www.mcelimited.co.uk

Pinnacle Machine Tools

www.pinnacle-mt.co.uk