Cobot investment takes machine efficiency to a new level

A leading precision subcontractor has invested in its first collaborative robot (cobot) from Mills CNC Automation as a route to helping improve its productivity, efficiency and machine tool utilisation. PES reports

Irvine, Ayrshire-based NPI Solutions is a company committed to continuous improvement and best-practice and as such regularly monitors, collects and analyses machine tool performance data, calculating the effectiveness and efficiency (OEE) of the equipment it uses – the objectives being to accurately identify production ‘pinch points’, to remove and/or reduce the issues that cause machine downtime, and to make manufacturing processes as productive as possible.

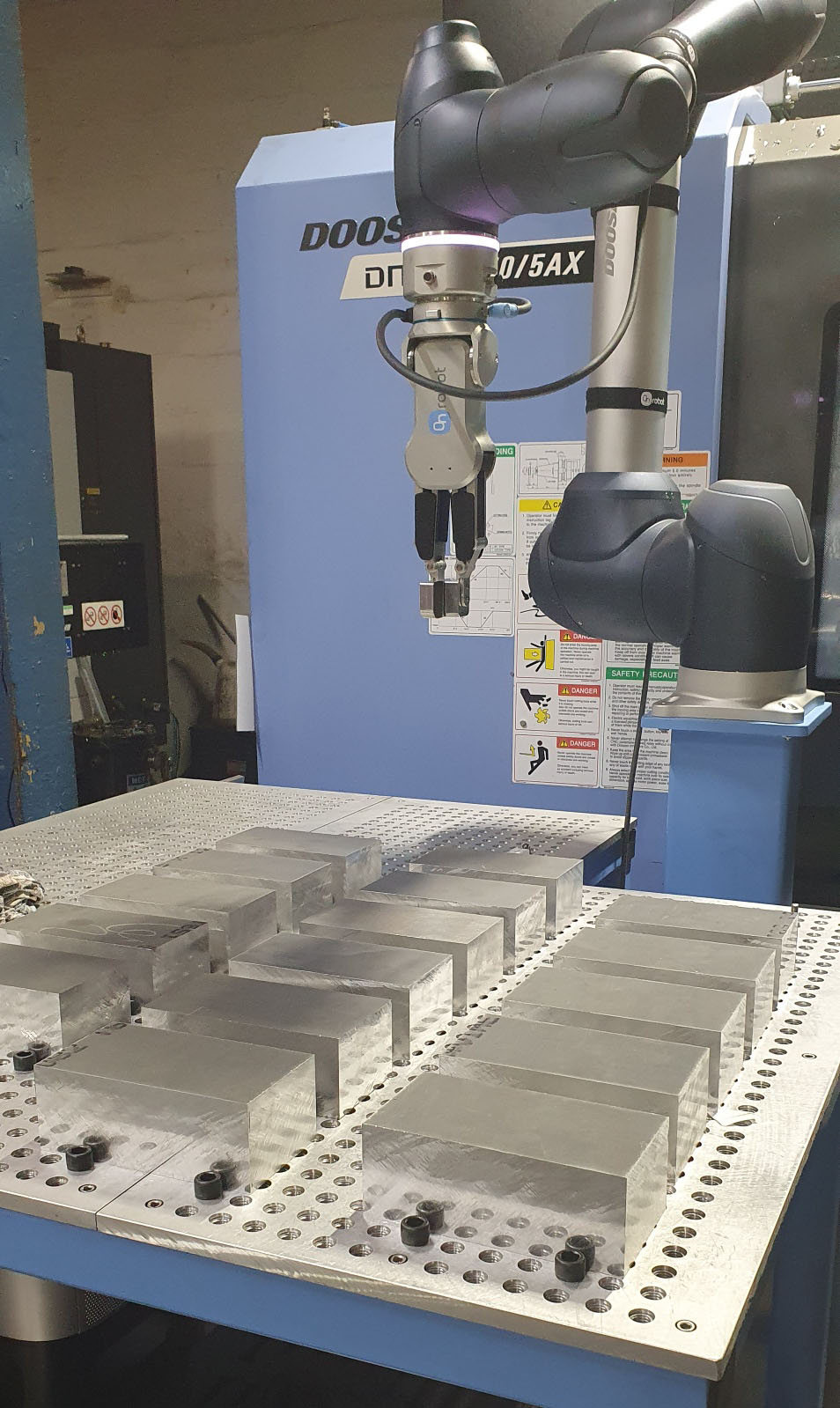

As part of this commitment, the company has recently invested in a new Doosan cobot from Mills CNC Automation. The M1013 cobot, with its 1.3m reach radius and 10kg payload, was delivered to the company in September 2020 and was integrated with a Doosan DNM 350 5AX 5-axis machine previously acquired by NPI from Mills CNC in 2016.

Since being installed the cobot has proved its worth by helping NPI optimise the DNM 350 5AX’s spindle uptime, minimising operator interventions and dramatically improving the machine’s output.

NPI’s managing director, Kevin Priestley comments: “We invested in the Doosan 5-axis machine tool to help make us more productive, efficient and competitive. The ability to machine precision parts in one set-up, via 3+2 and 4+1 machining was the appeal, and the goal.”

However, analysis of the machine’s performance over a period of time revealed that it was failing to deliver the expected results.

“It wasn’t the machine’s fault”, Mr Priestley explains. “It was directly related to the type of production work we do which is characterised by low volumes, small batches and short part cycle times.”

Being a high mix, low volume component manufacturer meant that the DNM 350 5AX could be idle for long periods each day to allow for frequent job set ups and changeovers to occur.

“Machines don’t make money if they are not making chips so to improve our profitability we needed to increase the DNM 350 5AX’s spindle up-time so we decided to look at automation,” Mr Priestley affirms.

The automation decision

NPI is no stranger to automation or to unmanned operations having previously invested in high-performance bar feeders to increase the productivity and performance of its CNC turning operations.

To increase the productivity of the DNM 350 5AX machine, the company explored a number of automation options before deciding on the cobot investment: “There were a number of potential automation solutions available,” Mr Priestley affirms. “We looked at automatic workpiece pallet change systems and industrial robots but their cost, floorspace requirements and complexity ruled them out.

“We needed a more economically-viable and simpler solution: one that could be quickly installed to transform the DNM 350 5AX into a flexible, automated manufacturing cell. We had investigated collaborative robot technology previously – the versatility of cobots in addition to their safety, their relatively lower investment cost and their ease of deployment were attractive propositions.”

He continues: “When we found out that Mills CNC, through its newly-created Automation Division, could supply us not only with a Doosan cobot but also project manage and undertake its installation and provide comprehensive training and applications support, we decided to put our plans into action.

“We visited Mills’ Automation’s facility in Leamington to meet the application engineering team and discuss our specific requirements with them in more detail. Ultimately everything got the green light.”

Doosan cobot: its operation and impact

To undertake what are essentially machine tending operations NPI worked alongside Mills CNC Automation engineers to identify the right cobot for the job. The model selected (based on the dimensions and weight of parts machined on the DNM 350 5AX) was the M1013.

The M1013 has a 10kg maximum payload and a 1.3m reach. It features six high-torque sensors which provide collision protection and was supplied to NPI with a controller, a teach pendant, a RG6 (OnRobot) gripper and a Schunk workholding package.

Situated adjacent to the DNM 350 5AX which, as part of the installation was fitted with an automatic door opening/closing facility, the cobot is programmed to pick up blanks positioned on a peg table and load them, in turn, into the machine where they are machined to completion.

Once machining operations have been completed, the cobot takes the finished machined component from the machine and places it back on the peg board in its predetermined position. This cycle is then repeated, with no operator intervention, until all the parts have been machined.

Parts machined on the DNM 350 5AX are typically made from aluminium. They vary in size from 15mm x 15mm x 15mm at one end of the spectrum through to 150mm x 150mm x 20mm at the other. Cycle times can be as short as two minutes or up to 60 minutes depending on part size, complexity and features.

Kevin Priestley adds: “The ambition to create a flexible automated manufacturing cell has been realised through the cobot investment. During the day the cell is programmed to machine components with relatively short cycle times unattended allowing operators to work on other machines or perform other tasks. For parts with longer cycle times the cell is programmed to run attended overnight.”

The new cobot cell has helped NPI improve its productivity, efficiency and competitiveness significantly. The DNM 350 5AX is now running at 85% efficiency as opposed to just 50% efficiency prior to the cobot investment.

Rapid return on investment

Mr Priestley is quick to acknowledge the skill and expertise of Mills CNC Automation’s engineers in designing and installing its new flexible automated manufacturing cell: “Everything went smoothly – from the design of the system through to its installation, proving out and onsite and remote training,” he says.

“Mills CNC Automation’s Peter McCullough and Cris Hearty took the time to understand our requirements. They demonstrated the productivity gains we could expect to realise from the investment up front - and they have been proven right. Mills’ support throughout has been first-class.”

NPI’s automated cobot cell has been operational for six months. Such have been the productivity and efficiency improvements realised in such a relatively short space of time that the company is now actively considering investing in a second cobot.

“Despite the pandemic and subsequent lockdowns, we have been unbelievably busy over the last 12 months,” Mr Priestley concludes. “To meet rising demand from customers, we will be investing in more automation in the near future.”

NPI Solutions www.npi-solutions.com

Mills CNC www.millscnc.co.uk