Enhanced EDM

Mitsubishi Electric used the MACH 2018 exhibition back in April as the platform to introduce a new CNC control unit on its established MV series of EDM machines.

The Mitsubishi EDM stand at MACH was furnished with the MV1200S and the MV2400R series of EDM technology that introduced the latest advancements in Industry 4.0 and power supply technology.

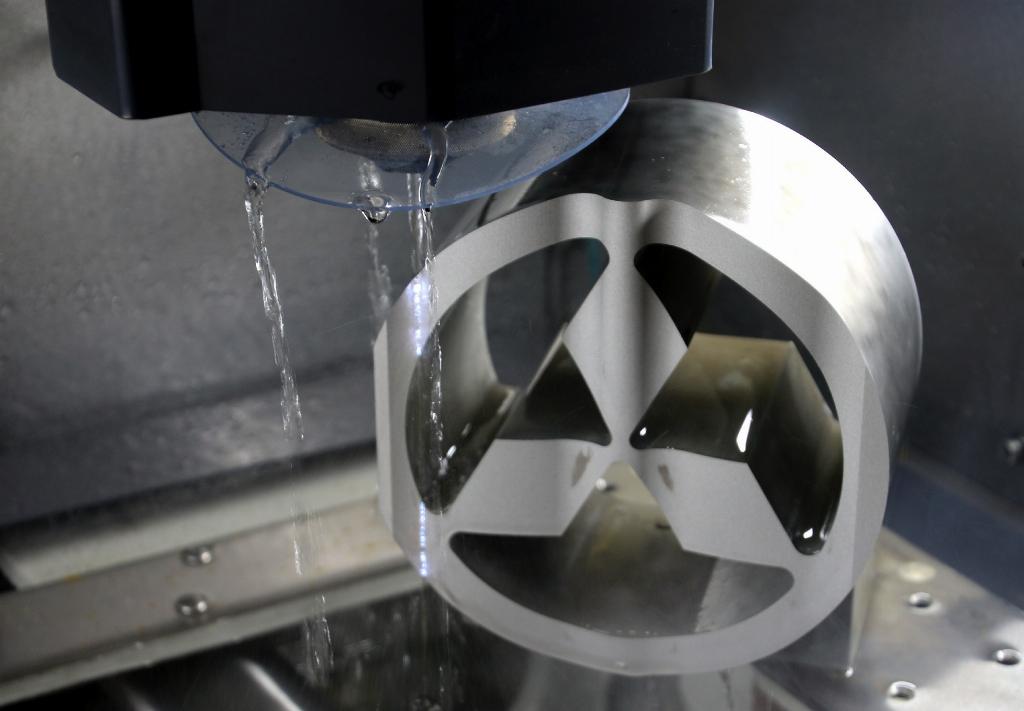

The compact MV1200S machine with its 400 x 300 x 220mm (X, Y, Z) axes travel offers cost-effective production in a small footprint whilst the larger MV2400R featured Mitsubishi's V350-V AEII power supply DMX-S (digital matrix sensor) that shapes each spark to reduce electrode wear considerably and – said to be the world’s first – linear shaft drive system XYUV. This combination delivers smooth, precise, highly controllable movements and high levels of productivity.

Quality is in the DNA of the Mitsubishi brand and the MV-R and MV-S series both feature the pre-installed crash protection system, intelligent auto wire threading, the latest Power Master control for process stability and a host of additional innovative features.

Central to both machines on the stand at MACH was the innovative new CNC control system. Globally launched at EMO 2017 and receiving its UK exhibition premiere at the NEC, the new system was designed with Industry 4.0 in mind.

Advanced technology and a new user interface can be a daunting prospect for any machine operator but Mitsubishi Electric has overcome this by offering both the new and established interface in a single control. With the flick of a switch, the new CNC interface can revert to either type, offering existing and experienced users a familiar interface whilst providing all the benefits of the new technology.

The machine operator has a large screen monitor and modern gesture controls that boost comfort with a configurable interface that supports the user by allowing the main function elements to be freely arranged for daily work. Furthermore, the step-by-step dialogue guidance pilots less experienced operators through the entire process with checklists taking operators from programming through to machining.

Completely tailored to the needs of the end user, the user interface has an easy-to-grasp display with all the machining parameters in configurable form to make everything visible. For scheduling, support is provided with an overview of remaining wire, filter cartridge state and other parameters. All documentation for the machine, including maintenance instructions and manuals are comprehensively integrated into the software with 3D diagrams and images also included to guide the user through every facet and process of the machine.

The new interface also provides integrated job scheduling, work planning and high levels of detail, memory capacity and power offering the end user real-time measures of consumable life, maintenance scheduling, power consumption, wire consumption and even cost per part or cost per hour based on the live-feed of operational parameters.

Putting the user in complete control, the intelligent new interface allows operators to monitor the machine portfolio from anywhere at any time. Powered by Teamviewer, customers can access their machines via mobile technology such as phones and tablets with direct status reports available via email.

Mitsubishi EDM www.mitsubishiedm.co.uk