Multi-faceted 5-axis 30-taper VMC

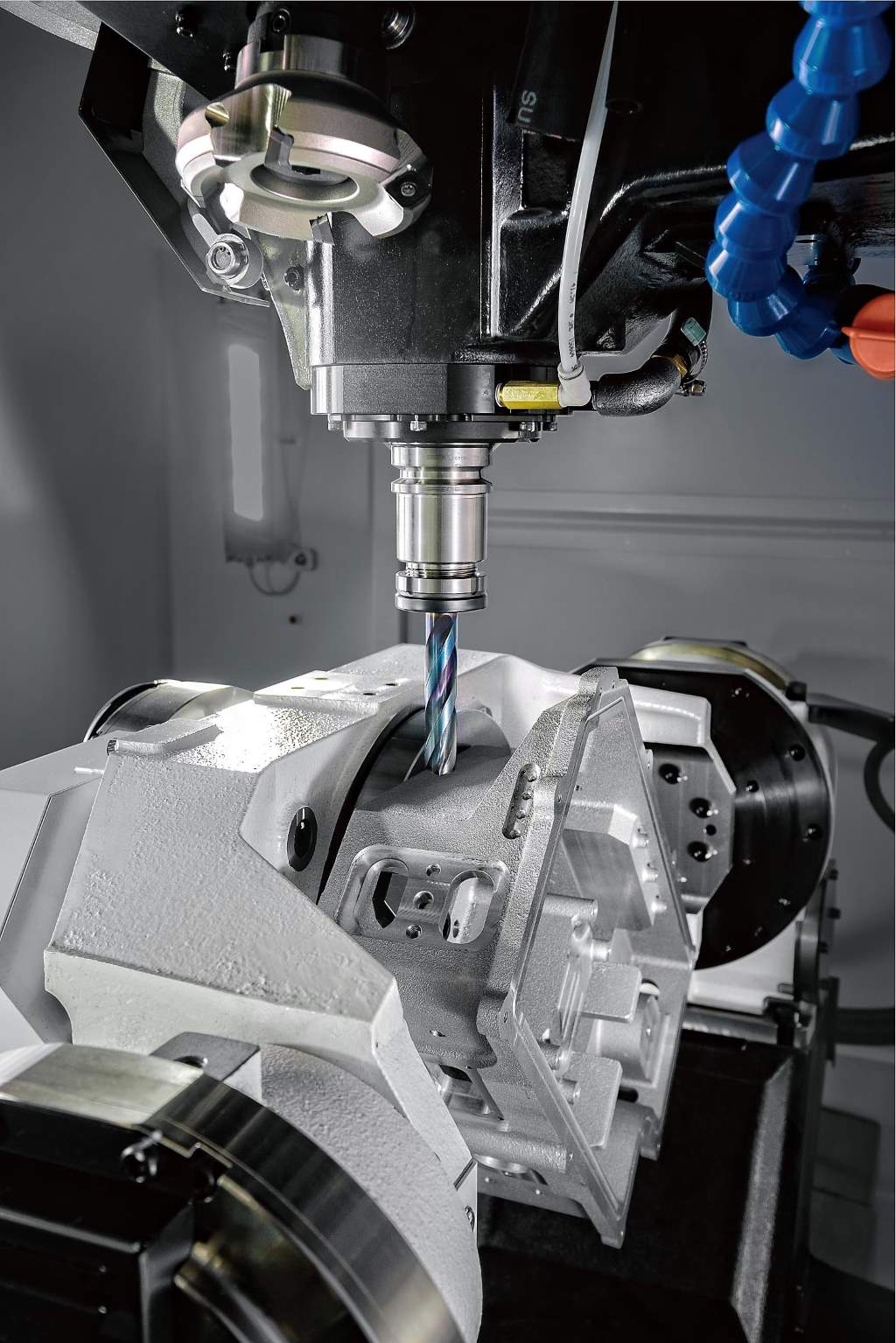

30-taper vertical machining centre (VMC) manufacturer Brother, has introduced a new 5-axis model with a swivelling rotary table, the Speedio U500Xd1.

Despite having a nominal footprint of just 1.5 by 2m, it is capable of multi-face machining of components up to 500mm diameter by 270mm high and weighing up to 100kg.

Combined with a 28-position magazine for tools weighing up to 4kg and either a 10,000rpm/18.9kW or 16,000rpm/15kW spindle with a face-and-taper interface option, the production centre redefines machines in this class and is squarely aimed at competing with 40-taper machining centres. 30 or 70 bar through-tool coolant is available.

Sole sales and service agent in Britain and Ireland, Whitehouse Machine Tools, claims there is little competition to the machine on the market in terms of its sheer speed of operation. Rapid traverse is 50m/minute in X: 500mm and Y: 400mm and even faster in Z: 300mm, which accelerates at 2.2g up to 56m/minute. Chip-to-chip time is 1.3 seconds, or faster still if a 14 or 21-tool magazine is fitted. Cutter exchange and axis motions take place simultaneously to minimise cycle times.

Trunnion swivel (A-axis) at 50rpm is a generous -30/+120° and the table (C-axis) rotates at 75rpm. Roller gear cam mechanisms drive both rotary axes and 0-90° indexing times are 0.9 seconds and 1.2 seconds respectively. Clamping torques are high at 610Nm and 500Nm.

Lowering the power consumption of its machines has long been Brother's aim. For a start, the electricity and air used by a 30-taper machine is only about 20% of that required by a 40-taper machine.

In addition to having a low inertia spindle and highly efficient spindle motor, the U500Xd1 is equipped with a power regeneration system that reuses energy generated when the spindle motor decelerates. Other energy saving measures include efficient filtration that limits the size of the pump needed, a low energy LED work light with automatic off function, automatic coolant off, standby mode and automatic power off.

Control of the machine is via Brother's latest CNC-D00 with 15-inch LCD touch panel, offering extended look-ahead and enhanced usability. The home screen displays the total and remaining cycle time, workpiece counter, remaining tool life and shortcut keys, without having to scroll through a menu.

Support apps have been incorporated to give an overview of production and operational status, load monitoring, power consumption, tool set-up and adjustment, recovery support and cycle time optimisation.

Whitehouse Machine Tools

www.wmtcnc.com