October cover story: Productivity is power

A new agreement between the nuclear industry and government aims to deliver billions of pounds in contracts to UK manufacturers, but sets challenging targets for cutting costs in new build and decommissioning. Tim Chapman of the Nuclear Advanced Manufacturing Research Centre explains what manufacturers need to know about the nuclear sector deal, and how the centre can help them win work.

A new agreement between the nuclear industry and government aims to deliver billions of pounds in contracts to UK manufacturers, but sets challenging targets for cutting costs in new build and decommissioning. Tim Chapman of the Nuclear Advanced Manufacturing Research Centre (Nuclear AMRC) explains what manufacturers need to know about the nuclear sector deal, and how the centre can help them win work.

Nuclear can be a tough market for manufacturers to break into – due mainly to the stringent quality requirements of the industry's top tiers – and even when you're in, global competition and cost pressures make it a challenging business. But for manufacturers who can meet all the demands, it can be a very rewarding sector to work in.

To help the UK supply chain win more work at home and internationally, the nuclear industry and government have agreed a variety of initiatives to improve competitiveness and drive the development and use of advanced manufacturing technologies. This is the nuclear sector deal,

launched in the summer as part of the government's industrial strategy to boost productivity, employment, innovation and skills across the country.

The deal was developed by the Nuclear Industry Council, an advisory group drawn from industry, government and regulators, including the Nuclear AMRC. Part of the national High Value Manufacturing Catapult, and based at the University of Sheffield, the Nuclear AMRC is dedicated to helping UK manufacturers win work in the sector.

Cost challenges

The deal comes at a challenging time for the UK nuclear industry. Our current fleet of reactors generate around a fifth of domestic electricity, but all except for Sizewell B are scheduled to shut down by 2030. Construction is well underway at the first of the proposed new fleet, Hinkley Point C in Somerset, but other new build projects are slow to get off the drawing board.

In large part, the delays are due to the challenges of financing these extremely complex multi-billion pound projects, at a time when the costs of renewables are rapidly coming down. The £92.50/MWh strike price agreed by government for Hinkley Point C does not look attractive when compared with £57.50 for the latest offshore wind projects, and is now seen as the high-water mark for nuclear.

As part of the sector deal, the nuclear industry has committed to achieving a 30% reduction in the cost of new build projects by 2030. The current cost estimate for Hinkley Point C is around £20 billion, so such a reduction will save billions on each new reactor. Delivering that will require intensive investment into developing advanced manufacturing and construction techniques to minimise costs and risk, as well as supply chain development to improve productivity and performance at all tiers.

The deal also targets a 20% reduction in nuclear decommissioning costs, compared with current estimates of £119 billion across the Nuclear Decommissioning Authority (NDA) estate plus £19.5 billion for EDF’s current fleet. The UK’s decommissioning programme is worth around £1.8 billion a year to the supply chain, and currently offers the biggest opportunities for it. The NDA currently works with around 3,000 direct suppliers, and aims to spend at least 31% of its budget with SMEs by 2020.

In return for these industry commitments, the Government is funding programmes worth over £200 million in total. Several have been announced before, but the sector deal ties them into an integrated package of industrial support which could prove game-changing for the sector.

Manufacturing innovation

Advanced manufacturing innovation is at the heart of this national effort to drive down costs by demonstrating new ways of making key high-value components for the build, operation and decommissioning of nuclear power plant.

The sector deal offers funding of up to £32 million for an advanced manufacturing and construction programme, to support a number of representative-scale build projects using factory-build techniques, modular and advanced construction processes, digital engineering and other methods. These collaborative projects will bring together the industry's top tier with manufacturers, universities and specialist research centres, with the results fed through the UK supply chain.

The research programme will target both near-term opportunities to tackle current manufacturing challenges and help UK suppliers win work, and longer-term opportunities to develop innovative techniques for future reactors.

In the near term, research supported by the sector deal will focus on optimising technologies and processes which are already accepted by nuclear codes and standards, and adapting techniques from other sectors such as oil and gas, aerospace, automotive, marine and rail. One example highlighted in the sector deal is electron beam welding, which can reduce cycle time for large fabrications from days to hours, but which isn't yet accepted by the nuclear codes.

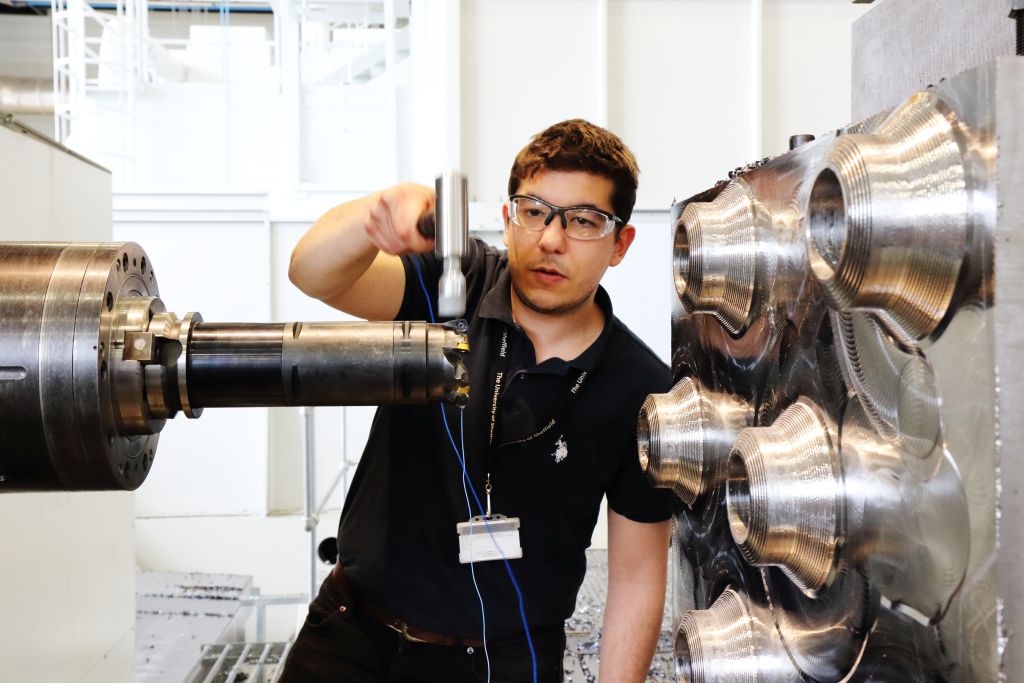

Advanced machining technologies, from cryogenic coolants to on-machine inspection, will of course be vital to improving productivity. The extremely large size of many nuclear components, allied with strict precision and quality requirements and a high cost of raw materials, presents significant challenges for standard machining processes.

A recent project at the Nuclear AMRC shows the kind of improvements that can be achieved through process optimisation for large demanding parts. In a collaboration with Sheffield Forgemasters, funded by Innovate UK, the centre's researchers used a range of advanced techniques including tap testing, dynamic analysis and toolpath optimisation to cut the time for rough milling a large nuclear forging by more than 40%.

In another ongoing project called Simple, the Nuclear AMRC is working with academic and industry partners to integrate a range of technologies and operations into a single manufacturing platform. By combining advanced machining, welding, cladding and inspection tools into one integrated system, the project aims to reduce cycle time and cost by at least half for a variety of large complex components such as pressure vessel sections, large valve casings and decommissioning waste containers.

Another key area is modular manufacturing, which can significantly reduce construction risk and help deliver new power stations to schedule and cost, and is key to proposed new designs of small modular reactor (SMR) and advanced modular reactor (AMR). Modular techniques are already well established in the shipbuilding sector, and the Nuclear AMRC last year opened a modularisation R&D facility at the Birkenhead site of its member company Cammell Laird.

These new modular reactors offer a unique opportunity for the UK to regain a global lead in reactor technology. The sector deal includes up to £44 million for R&D to support the early development of new designs, plus up to £12 million to help regulators prepare for these new technologies, and £40 million for a new thermal hydraulic testing facility to support later stage development.

And for the generation beyond that, the sector deal confirmed an £86 million investment to establish a new Nuclear Fusion Technology Platform at UKAEA. The new facility, expected to open in 2021, aims to secure around £1 billion in contracts for UK suppliers from the ITER fusion research project in France and other global fusion projects.

Supply chain support

To help smaller UK manufacturers access higher-value contracts and enter new nuclear projects, the sector deal also offers up to £30 million for a national supply chain programme. As quoted in the deal, the Nuclear AMRC estimates that a successful programme would create or sustain up to 12,500 jobs and up to £2 billion domestic and international contract wins by 2030.

The new programme will build on the established success of the Nuclear AMRC's Fit For Nuclear (F4N) and Civil Nuclear Sharing in Growth programmes. Together, the two programmes are estimated to have delivered over £1.4 billion of new contracts and created or sustained over 7,500 jobs.

Since its launch in 2011, F4N has become a widely-recognised industry benchmark for nuclear-ready manufacturers. Hundreds of companies have now used the F4N assessment to measure their operations against the standards required to supply the nuclear industry, with around 150 being granted F4N status after implementing a bespoke action plan to close any gaps in performance.

By its nature, the nuclear power sector will always be a challenging market for manufacturers. But with the industry and government committed to supporting the supply chain through the sector deal, and the opportunities to drive technical innovation through collaborative R&D and transfer best practice from other sectors, there's probably never been a better time to get involved.

Nuclear AMRC www.namrc.co.uk