Zero-waste, carbon neutral

Responsible manufacturers are rightly placing zero-waste and carbon-neutral ideals at the top of their company policy commitments. Mazak Europe is no exception, however, making a policy into a legitimate and sustainable part of the production process requires imagination.

Oemeta has been producing high-performance cutting fluids for over 100 years, and its R&D, based in Hamburg, has been working with significant global manufacturers to develop and perfect an extensive range of compatible production process fluids. One being the Hycut Multi-functional Oil (MFO) range which can be used in a multitude of ways to reuse and recycle in most production applications.

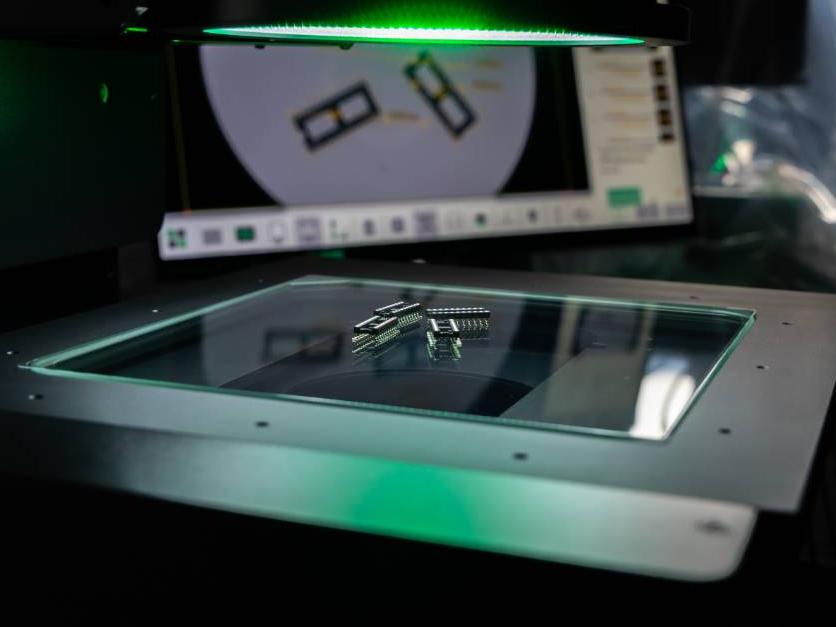

At its European manufacturing plant in Worcester, Mazak has as part of its waste reduction strategy introduced a zero-waste process onto the production wash machines. Normally, over time, the washing solution used for cleaning components becomes saturated with oil-containing metalworking lubricants, requiring the wash cleaner to be drained and thrown away.

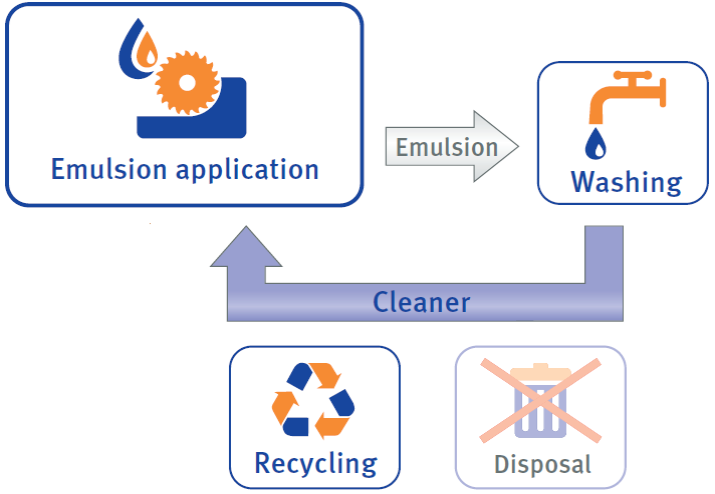

Compatible cleaners from Oemeta were introduced into the wash machines at Worcester, and the process optimised. The wash tank automatically pumps a small percentage of the used wash back into the production cutting fluid tanks every few days.

This brings multiple advantages. The washed off coolant residue and wash water are returned back to the process for re-use. The Oemeta wash cleaner consists of ingredients that boost the process cutting fluid's corrosion and bio-protection packages, reducing cutting fluid top-up and consumption. The final significant advantage is that with regular recycling the wash machine requires very little in the way of downtime or cleaning, and remains at optimal cleanliness levels at all times.

Oemeta UK https://uk.oemeta.com