On the rails

As one of the UK’s leading suppliers of machine tools focusing on high precision CNC machines and flexible manufacturing systems, Matchmaker CNC has a broad spread of customers across a range of industry sectors – rail being a good example. The company claims its Unisign range of machines is ideally suited to this type of work.

By combining its in-house expertise and the range from Unisign, Matchmaker CNC is able to tailor machine tool solutions to the needs of its customers and enhance their productivity through industry best practice. This ability is becoming ever more valuable to its clients which operate in environments of constant change with pressure to deliver on time at competitive prices.

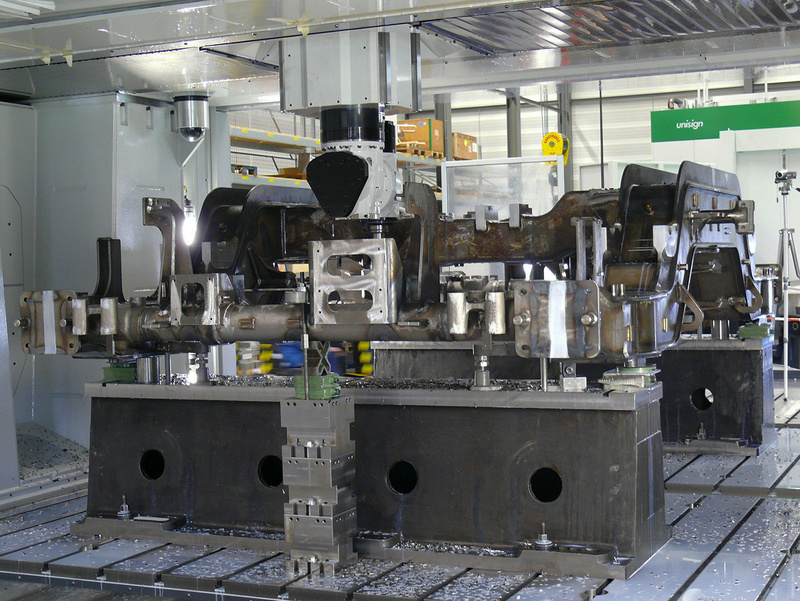

An example of this is the Uniport series of machining centres; with a moving portal bridge in the X-axis, they are ideal for large and voluminous products such as railway bogie frame machining. Sitting in the middle of this range is the Uniport7000 with the option of 5-axis operation. The design of the machine, which features a ‘box in box’ style construction, creates a highly rigid machining platform from which five-sided machining can be carried out. Furthermore, the scale of the machine, with a table measuring up to 18,000mm long and 4,500mm wide allows for large components to be mounted side by side to facilitate pendulum machining to further enhance productivity through reduced changeover times.

The key benefits of the machine are its ability to facilitate rapid changeover times, a high capacity toolchange system, and an accessible machine bed making load/unload simple. The general construction of the machine ensures a stable machining platform which in turn guarantees accuracy and performance. The ability to access five sides of the component inside and out, in a single set-up, also increases uptime and eliminates handling of large components. The machine bed is built into the factory floor so making access to the workpiece straightforward, with the operator having the ability to step onto the table, when it is safe to do so, to inspect the workpiece or make any adjustments to the clamping that are required.

While rigidity is the name of the game when operating the Uniport7000, when specifying the machine total flexibility is the operative phrase. The customer can specify the machine in many ways, including as a high-rail gantry machine. In addition the bed length and table width can be specified to suit, from 4,000mm to 18,000mm in the X-axis and 2,500mm to 5,000mm in the Y-axis. In addition there is a wide range of options to choose from such as spindles, machining heads, and even a carousel turning station to add turning capacity to the machine.

With countries around the world looking to invest in rail infrastructure, and closer to home the potential that HS2 may bring for significant investment, Matchmaker CNC is confident that this sector will provide great opportunities for the expertise and technical products that it has.

“With all that is happening in the rail sector we are confident that 2016 will be another positive year for us – albeit with a few challenges along the way – but by combining knowledge and product we are confident that those challenges will be met and business will continue to grow,” Mr Maskell concludes.

Matchmaker CNC www.matchmakermc.co.uk