Parabolic Performance Cutting world première

Perfect surfaces on complex geometries with reduced process times – the Hoffmann Group has developed a new generation of milling cutters for Parabolic Performance Cutting (PPC) that claim to do just that.

The new Garant solid carbide barrel milling cutters are optimised for the finish machining of freeform surfaces and are ideal for machine tool building, toolmaking and mould making.

Modern CAD/CAM systems have the capability to create particularly sophisticated milling strategies. PPC is a further development of ball-nosed slot drilling and is a relatively new discipline, also called barrel milling. The prerequisites for PPC is a modern 5-axis milling machine and CAD/CAM software which allows the tool geometries to be processed as a data model, thereby supporting the PPC process.

The main cutting edge of PPC tools is curved, as an arc of a larger radius circle which allows significantly larger effective radii to be employed. The new Garant solid carbide barrel milling cutters facilitate a line skip up to nine times greater than with a ball-nosed slot drill of the same diameter, whilst achieving the same surface quality. The result is significantly shorter process times and less stress on the workpiece, tool and machine. If on the other hand the same line skip is maintained, a surface quality up to 80 times better can be achieved.

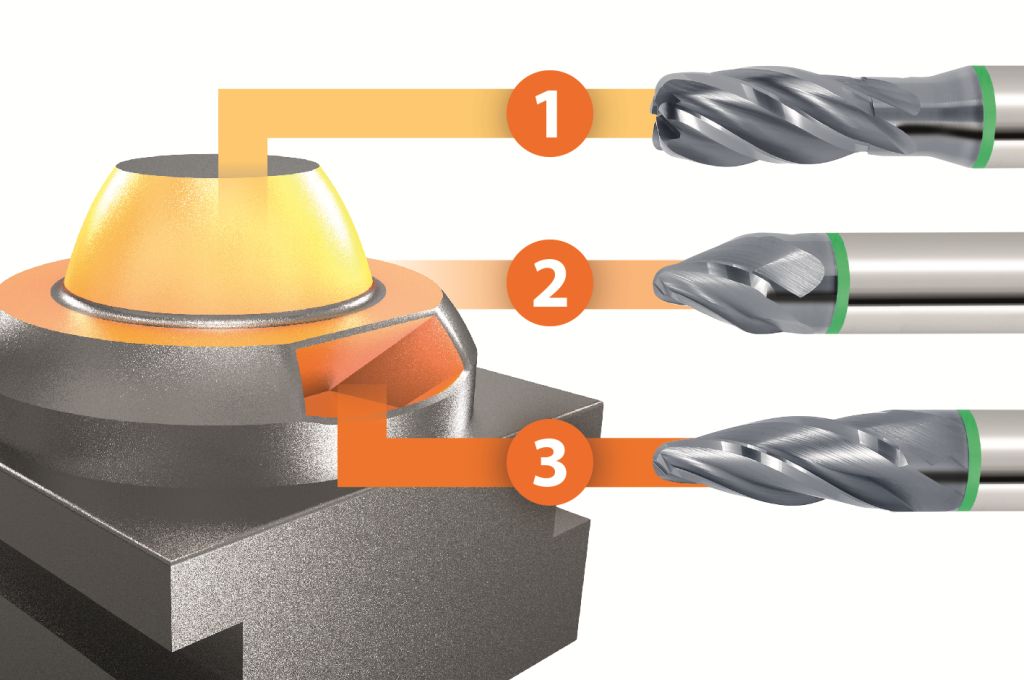

To fully exploit the advantages of PPC, the effective radius of the curved main cutting edge must be matched as closely as possible to the demands of the workpiece surface to be machined. Garant solid carbide PPC barrel milling cutters are available in three basic forms: straight, tangential, and conical.

The straight form is for machining freely accessible surfaces, without obstructive contours. The conical form on the other hand is for machining workpieces with obstructive contours, and for large areas. Here the tool, as for the tangential form, is always aligned for an oblique approach. The tangential form also allows machining of deep cavities that are difficult to access.

CAD/CAM-controlled production using PPC enables especially economic and precise machining strategies, coupled with high process reliability. Appropriate tools for implementation of these strategies are now available from the Hoffmann Group. The new PPC tools are suitable for machining materials from mild steel through to tool steel. Garant tangential form barrel milling cutters are also available for machining stainless steels and high-temperature materials.

Hoffmann Group www.hoffmann-group.com