Pushing the fibre boundaries

No-one in their right mind could accuse Tividale, West Midlands-based Accurate Laser Cutting of not investing in its future. When Dave Tudor visited the company just over a year ago, it had just spent a cool £1 million on new press brake and laser cutting equipment. Now a year later the business is really pushing technology to its limits with the purchase of a10kW laser cutting machine from Bystronic – said to be the first of its kind in the UK.

There’s nothing like an economic bombshell to really put the cat amongst the pigeons is there? I am of course referring to the UK’s decision to leave the European Union following the now infamous referendum on 23rd June. It would be true to say that an air of uncertainty has swept across the UK – not helped at all by a Government that seems to lack a master plan to steer us through the turbulent waters.

Companies will deal with the uncertainty as they see fit, but in many respects it’s business as usual for Accurate Laser Cutting. “There’s no doubt that the marketplace is flatter than it was a year ago but through an ongoing marketing campaign and an unrelenting willingness to invest in the latest technology we’ve actually increased our turnover,” enthuses company director Steve Morgan. “What I can say beyond any doubt however is that without that approach, business levels would definitely have suffered.”

The cornerstone of Accurate Laser Cutting’s success is centred around offering rapid turnaround, high quality folding, cutting and bending services. It tends not to get involved with long-term project work but instead has found a niche processing small quantity batches quickly and efficiently. Indeed, it aims to process quotations within four hours and orders, depending on complexity, are usually delivered within 24-48 hours. It operates across two sites, seven days a week and even has its own delivery vans. It’s undoubtedly a successful formula – the company has in excess of 1,000 customers on its books.

“It may surprise some people that our average order size in terms of monetary value is only around £400,” reveals co-director, Jon Till, “and sometimes it’s as low as £50-60. It’s a successful business model for us because where we can really add value is with our rapid processing times. Ongoing investment in the latest technology means we can keep lead-times to an absolute minimum.”

Come on in CO2 your time is up

Around this time last year, Accurate Laser invested £500,000 in a Bystronic 6kW 4020 BySprint Fiber laser. Absolutely state-of-the-art at the time, the machine could process 4m by 2m sheet at high cutting speeds across a wide range of materials – including non-ferrous metals such as copper and brass.

I remember Mr Morgan stating at the time that the company’s next purchase would probably be an 8kW machine but that prediction proved to be somewhat reserved because Accurate Laser has actually just invested in the UK’s first 10kW fibre laser machine from Bystronic representing a whopping £750,000 investment.

Significantly, the new arrival marked the death knell for the company’s CO2 laser machines. Accurate Laser Cutting is now operating entirely with fibre laser technology so no more praying to the Gods regarding material reflections that could effortlessly destroy hundreds of pounds worth of lenses, mirrors and optics in an instant.

On a fibre laser all that needs replacing in terms of consumable items is a relatively cheap ant-spatter sacrificial lens and the nozzle. Running costs are also much lower on a fibre laser machine; Mr Morgan says that in terms of energy used, the 10kW variant uses 50% less electricity than his 6kW CO2 models.

“To keep abreast of the latest technology we tend to upgrade our equipment every three years but another factor in the equation was that our two 6kW CO2 lasers were out of warranty and becoming quite expensive to maintain,” he affirms.

“There were some 8kW fibre laser machines available in the marketplace but we’d heard from Bystronic that they were working on a ByStar 10kW model so we decided to bide our time. True to their word, at EuroBLECH this year they actually unveiled an 8kW and a 10kW machine at the same time. Opting for the latter was therefore something of a no-brainer.”

Real progress

By Mr Morgan’s own admission, whilst the 4020 6kW fibre purchased last year was a very fast and capable machine, it was still somewhat limited when processing the thicker 15, 20 and 25mm mild steel that makes up a substantial portion of Accurate Laser’s workload. The new ByStar 10kW model can process aluminium and stainless steel up to 30mm thickness, mild steel up to 25mm, brass up to 15mm and copper up to 12mm. He says that processing 20 and 25mm material is as fast as CO2. Previously this was a real limitation.

“Compared to our old CO2 lasers the speed of the new machine is frightening,” Jon Till states. “We were processing a job recently in 5mm thick mild steel at 16m/minute. With our 6kW CO2 lasers the maximum speed was only 4m/minute so that represents a fourfold increase. Cutting with nitrogen also means no oxidisation on the cut surface and excellent finishes.

“The 10kW machine can actually nitro-cut mild steel up to 15mm which will provide our customers with a vast improvement in cut quality,” he adds. “Previously with our CO2 lasers we could only nitro-cut up to 3mm thickness so that’s a huge increase in capability. Also, the clean-cut edge achieved from using nitrogen gas will help prevent further deterioration down the line with secondary ops like powder coating. Anything thicker of course would be oxygen cut.”

Supplier loyalty

Mr Morgan admits he is somewhat biased towards Bystronic equipment having worked there for 10 years prior to setting up Accurate Laser with Mr Till in 2005, but it was by no means done deal with the latest purchase: “The Trumpf 8kW disc laser came very close and it’s an excellent machine,” he says, “but at the end of the day we’ve enjoyed a strong working relationship with Bystronic for many years and they were offering the more powerful 10kW capability.

“The other deciding factor is that being so ‘Bystronic-centric’ already, we use their BySoft programming software extensively and we’re very familiar with it. Staying with the same supplier therefore made sound business sense and we know their service levels are exemplary.”

Accurate Laser’s relationship with Bystronic is undoubtedly close – so much so in fact that the two businesses work together to develop and fine tune processes. “We’ve been using Bystronic machines for 10 years now and we’ve evolved into becoming one of their test customers,” Mr Till explains. “It’s a partnership that works well – they provide the technology; we push that technology to its limits. I don’t think it’ll be too long before we’re nitrogen cutting 20mm thick mild steel. It’s just a matter of time.”

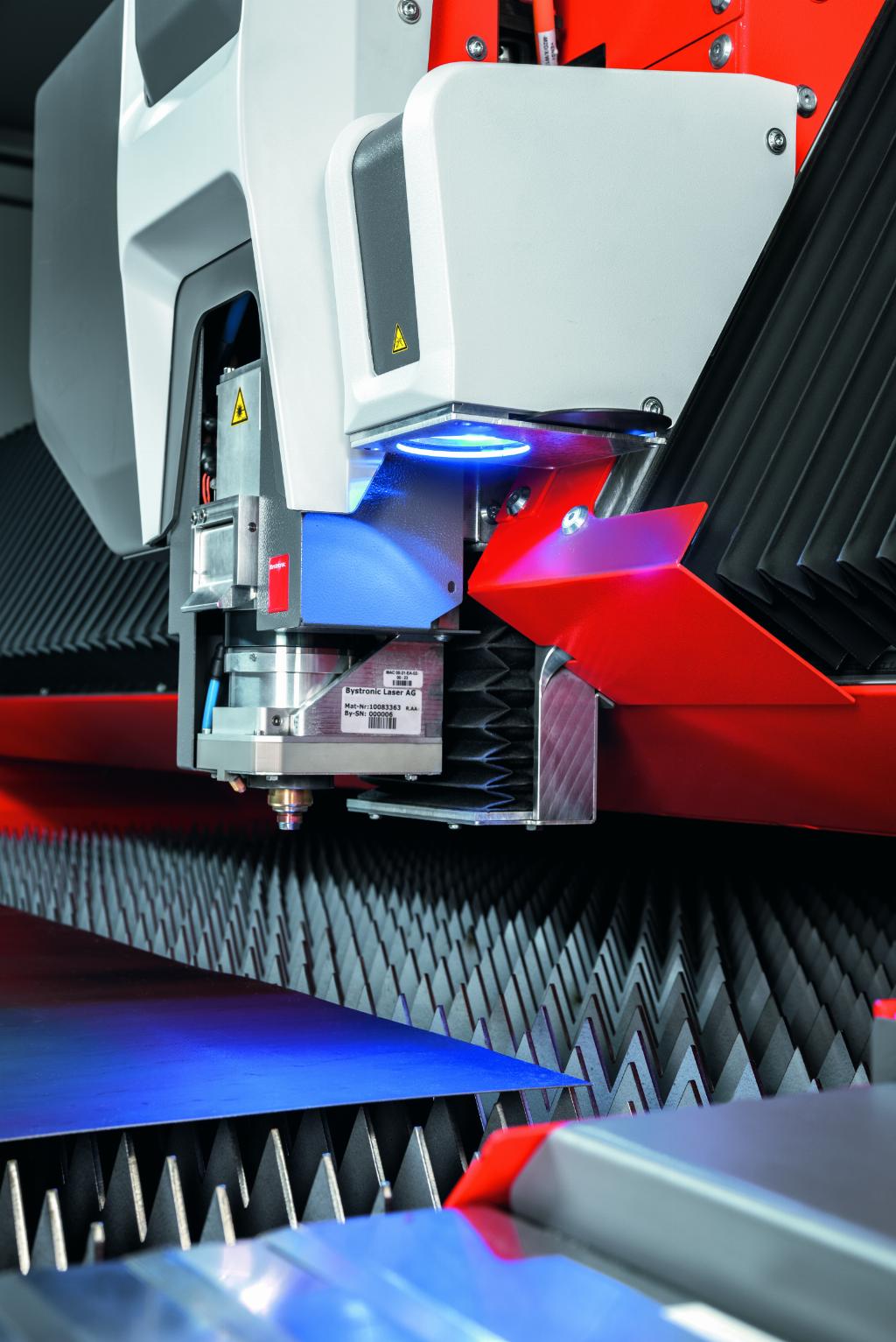

To integrate the 10kW fibre laser source optimally into the ByStar platform, Bystronic has designed and produced a new cutting head. The in-house development incorporates a ‘Spot Control’ function which automatically shapes the laser beam and flexibly adapts the focal point with high precision. Without operator intervention, cutting quality is optimised across a broad mix of materials.

Accurate Laser Cutting www.accurate-laser.co.uk

Bystronic www.bystronic.co.uk