OCTOBER COVER STORY: Reverse engineering a racing classic

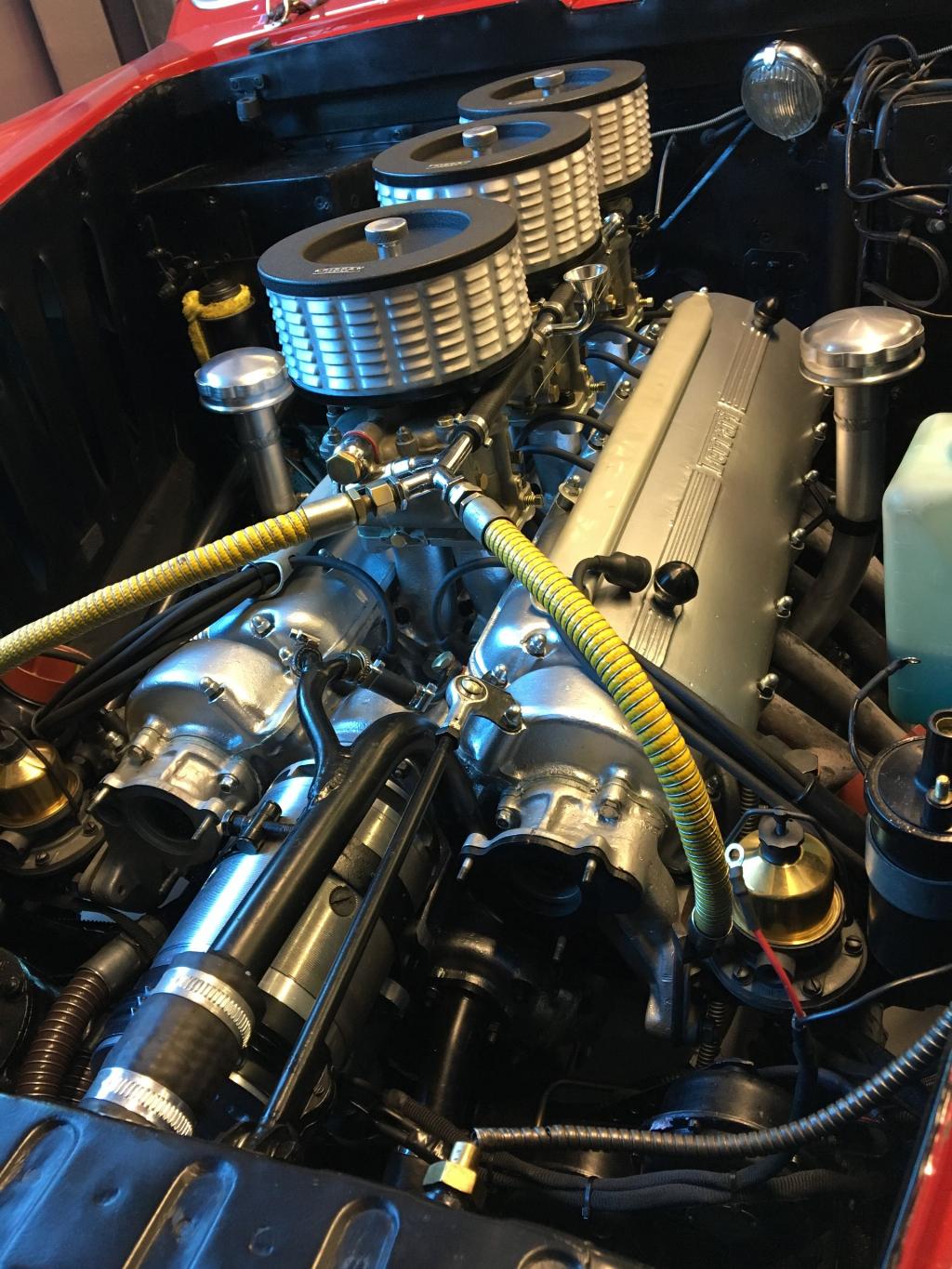

Classic car restorer Redesign Sport relies heavily on modern scanning equipment and manufacturing software to carry out its rebuilding projects. PES hears how applying this technology helped restore a rare Ferrari 225.

Gone are the days when a shortage of spare parts would see classic or historic cars retired from the road and then consigned to a museum.

By harnessing the latest scanning technology in conjunction with CAD software such as SolidWorks, the ability to reverse engineer obsolete parts provides the means to get these vehicles back on the road and prolong their lifespan.

Dafyd Richards is founder of bespoke car restoration company, Redesign Sport (RSL). Recently he was required to manufacture parts for a classic 1952 Ferrari 225. He turned to SolidWorks CAD software supplied by reseller NT CADCAM.

He begins: “We have been restoring historic vehicles since 2006 and certain parts are getting increasingly harder to source as the cars get rarer and rarer. In some cases, the vehicles we have coming through are one of a kind, so we realised that we need to take matters into our own hands.

“Classic car owners like to go racing or undertake long distance tours, but irrespective of how much the customer is willing to spend, these £1 million or even £20 million cars sometimes can’t go anywhere because sourcing old parts or getting them remade has previously been horrendously difficult.

“In the last three to five years, there has been a revolution and evolution in scanning technology; I remember when I first saw a FaroArm in action, then a Faro Focus 3D scanner; it blew my mind,” Mr Richards recalls.

“This technology offered the capability to scan old, broken parts and put the data into the 3D space for CAD modelling. Scanning massively improves the accuracy and time in reverse engineering these beautiful cars and their associated parts – and it also reduces the mental fatigue of the engineer, who would have previously relied on traditional methods – or worse, been forced to model a component from memory!”

“We undertook a great deal of market research before ultimately opting for a Creaform HandySCAN 700. I had a demo and the salesman was able to scan half the car in 15 minutes, so I knew it was a gamechanger.

“The scanner comes with VX Elements lightweight scanning software, which scans to mesh directly, as opposed to other scanners which scan as a point cloud and then convert to a mesh. This enables us to see information in real-time and, if need be, change the resolution or laser intensity immediately. For example, if I’m scanning across two different materials – say a highly polished red paint to rubber – I can change the shutter setting and alter the intensity of the laser halfway through.”

A black art

RSL also uses Romer Arms with Geomagic Design X software which allows the operator to convert the 3D scan data into high quality CAD models that can then be used in SolidWorks.

“For a long time, 3D scanning was almost a black art,” Mr Richards comments. “Many people think you need the most amount of data and information to reverse engineer, but sometimes it’s irrelevant because you can’t do anything with it. Scanning items and helping them get that scan data into a SolidWorks file is much of what RSL is about.

“Whether it is scanned data from a laser, geo satellite MMR or a photogrammetry scanner, we can process it, trim out the erroneous data that isn’t needed and then work with the customer to try and meet their aim. From there, we can help them get the relevant data into the SolidWorks environment.”

Mr Richards needed to use all his experience with scanners and SolidWorks when a customer in the US asked him to look after his 1952 Ferrari 225 for the Goodwood Revival.

He explains: “The car had been given a fresh engine build and a check over in the US, but when we fired it up a day before the race, a conrod came out of the side of the engine so the prognosis was terminal. Unfortunately, upon stripping the fresh engine we found that every nut and bolt inside had been left loose during the original rebuild. Needless to say, we missed the event, but the customer asked if we could get the car race-ready for the Monaco Historic Grand Prix. We only had eight weeks to turn things around.

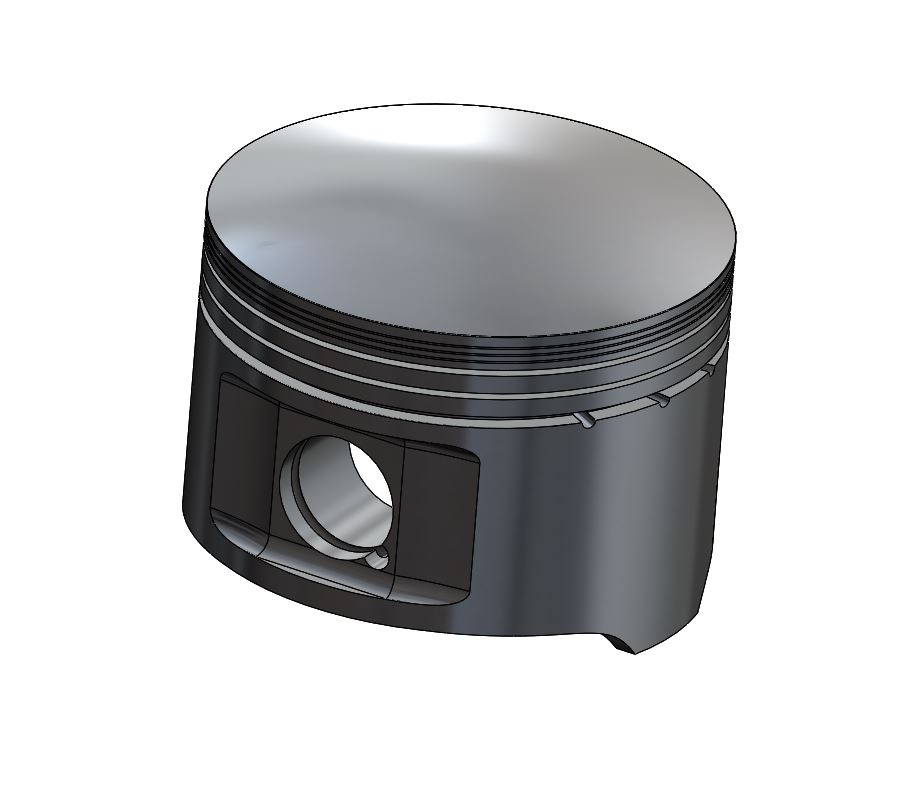

“We scanned the piston on a Thursday morning using the HandySCAN, modelled the scan data in Geomagic Design X then transferred it live into SolidWorks. Our chosen manufacturer uses SolidWorks for modelling where, if needed, they can tweak the design. eDrawings and part files flew back and forth, but by the Monday morning the 12 pistons went into production and we had them in our hands three weeks later.”

Distributing parts

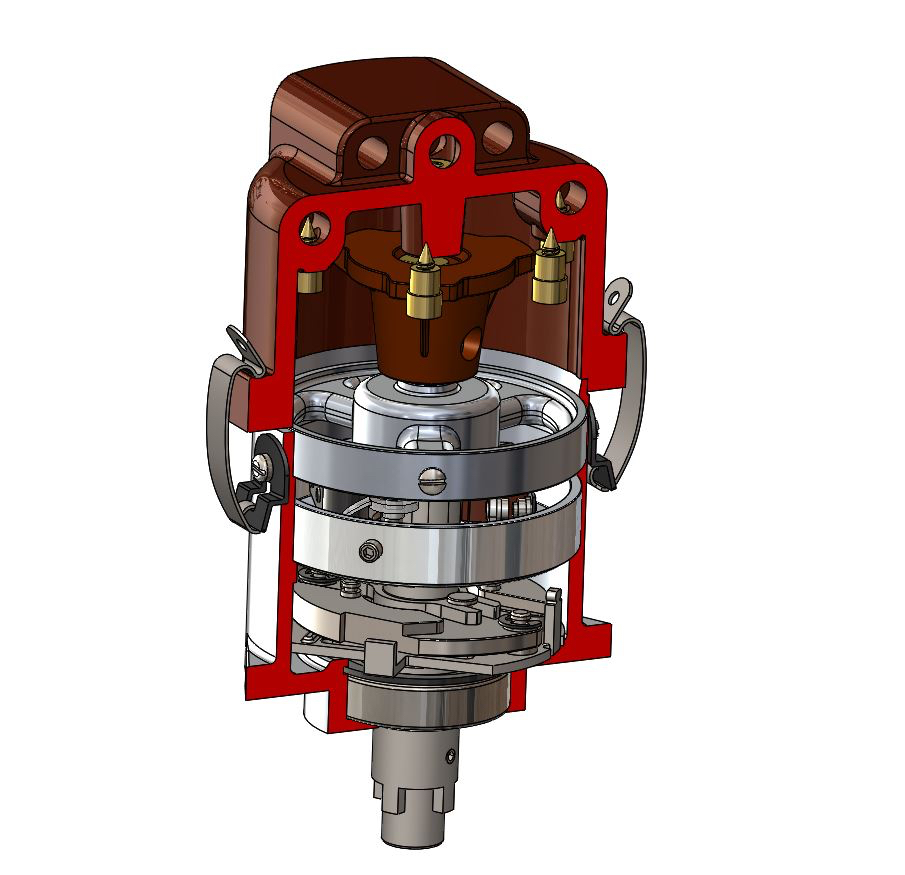

RSL also used SolidWorks to remodel two distributors on the Ferrari which were causing problems with the ignition system. It enabled it to remodel every single component and then send out all the parts to different manufacturers.

“The parts had only ever been seen together on the screen in SolidWorks, but when they arrived they all fitted together perfectly first time,” Mr Richards affirms: “The car drove magnificently in Monaco and after a quick check-up back in the UK, it was delivered to Heathrow for its flight back to the US.”

He concludes: “When I first discovered SolidWorks 3D CAD, I found it very easy and quick to learn. I have been using Geomagic Design X in real world projects for the past couple of years and between the two products, RSL has achieved a huge amount of success – especially the 2D drawing facility. In fact, I don’t believe there is a more complete CAD package on the current market.”

NT CADCAM www.ntcadcam.co.uk