Sodick announces patented new technology for ALC wire EDM range

Sodick has unveiled the new ALC i Groove edition – a range of innovative technology that will be standard for Sodick ALC400 and ALC600 category wire machines.

The i Groove developments have been driven by Sodick’s three ‘concepts of I’: Innovation, Intelligence and Initiative.

All models in the ALC400 and ALC600 range will be equipped with Sodick’s new, patented wire rotation mechanism, together with significantly improved Stepcut technology and a number of increased automation facilities, as well as larger dielectric tanks.

New wire rotation mechanism

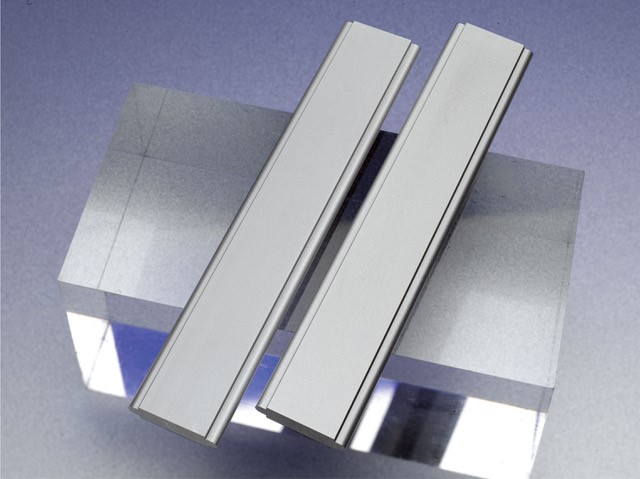

This newly developed technology, patented by Sodick, rotates the wire during the skim cut operation, so that workpieces are machined from top to bottom with the unconsumed surface of the wire.

Conventionally, wire electrodes are controlled solely by tension and running speed, while being constrained by a die. Sodick’s i Groove rotation mechanism provides additional control over the wire, resulting in increased surface quality and improved geometric accuracy, whilst at the same time minimising wire consumption – combining the best ecological solution with the highest quality of EDM machining.

Improved Stepcut technology

The i Groove technology incorporates Sodick’s new step machining functions, developed to easily and conveniently overcome issues such as the typical ‘streaky’ precision errors that can occur where the plate thickness changes suddenly, for example in a counterbore or hole.

Sample workpieces machined by Sodick using i Groove technology have shown that the streak shaped precision error can be reduced by up to 50% when compared to conventional machining.

To support the new facilities, the machining technology database has been expanded to include an even greater range of materials. In addition, i Groove enables users to select optimum conditions visually by using on-screen icons, while the mesh FTC function enables high precision groove and step machining even for multi-cavity finishes.

Increased facilities for automation

AL i Groove edition machines feature a number of advanced technologies to assist in increased automation including, of course, the use of Sodick’s reliable and proven in-house linear motor. Furthermore, the machines incorporate the FJ-AWT high-speed automatic wiring device with its sophisticated automatic recovery performance in the event of disconnection.

Enhanced management functions include digital machining fluid monitoring (filter pressure, fluid level specific resistance, fluid temperature) as well as TH COM – which minimises the effect of temperature changes within the machine, reducing the amount of thermal displacement by 50% compared to a conventional machine.

Another function, AIM (AI Maintenance), monitors and automatically diagnoses the status of the machine, including operation, maintenance and installation environment, boosting the machine’s operation rate, reducing machining defect rates and improving traceability.

Additional automation and labour-saving options have been added to the line-up including Sodick’s S3CORE automatic core processing device which keeps the workpiece from dropping after removal from the machine and automatically retrieves it, together with camera-type onboard measurement systems and enhanced compatibility with robotic automation.

In addition to all these technical features, i Groove edition machines also feature newly designed, larger capacity dielectric tanks (the ALC400G tank is increased from 675 litres to over 790 litres, and the ALC600G tank is increased from 850 litres to greater than 990 litres), with three dielectric chambers, which has resulted in a slightly increased machine footprint. Furthermore, the number of filters has increased from three to four in order to further increase filtration efficiency.

Sodi-Tech EDM www.sodi-techedm.co.uk