A festival of manufacturing down south

While the return to work after the Yuletide festivities may not be the most eagerly anticipated New Year event, engineers can draw some solace in the fact that the dull days of early January herald the imminent arrival of a much more colourful perennial event – the return of one of the UK’s favourite engineering shows, Southern Manufacturing 2020, taking place from February 11 - 13 at Farnborough International in Hampshire.

While the return to work after the Yuletide festivities may not be the most eagerly anticipated New Year event, engineers can draw some solace in the fact that the dull days of early January herald the imminent arrival of a much more colourful perennial event – the return of one of the UK’s favourite engineering shows, Southern Manufacturing 2020, taking place from 11-13 February at Farnborough International in Hampshire.

Read more of PES's coverage of Southern Manufacturing 2020 here.

Southern Manufacturing is indisputably one of the most important annual shows for the production engineering community, a festival of the latest machinery, tooling, production hardware and all manner of industrial goodies combined with some of the finest subcontract expertise in the country.

The organisers are expecting the 20,000m² Farnborough International Exhibition Centre to be full to total capacity, and are confident of topping last year’s record-breaking attendance, which came near to 9,000 unique visitors.

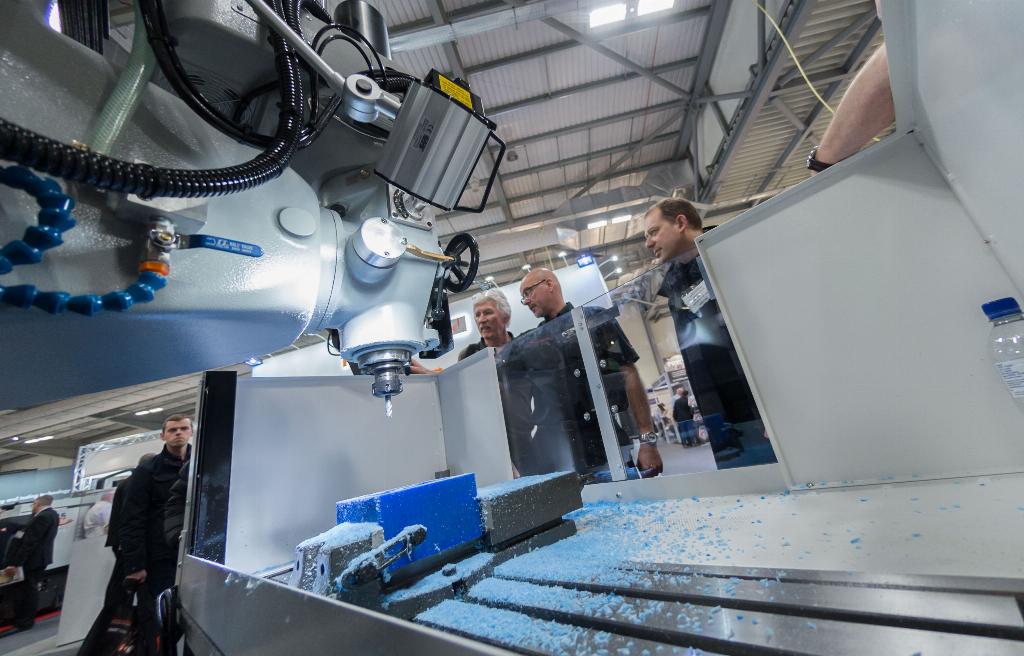

Visitors heading primarily for the mechanical engineering side of the show are traditionally the largest group, and not surprisingly given the location, aerospace, automotive and defence figure very prominently in the job descriptions of a large percentage of visitors. High on the must-see list will be the show’s Production, Machinery and Tooling section, with its wide selection of machine tools being put through their paces.

Aside from the well-known CNC machine tool brands at the show such as: Matsuura; Hurco; Mills CNC; XYZ and Mazak, additive manufacturing will be making a more prominent contribution this year. New products being presented by Laser Lines this year include the XM200C metal powder-bed fusion 3D printer from Xact Metal.

The XM200C is a compact and affordable system that can produce quality metal parts from a variety of metal powders at a low cost. Also demonstrated will be the new Method 3D printer from MakerBot that combines the speed and accuracy of an industrial 3D printer with the space-saving design of a desktop unit, plus the latest Form 3 3D printer from Formlabs.

Another interesting product on show on the Creat3D stand is the Nexa3D, which is capable of high-speed printing. Rapid 3D print technology enables tool-less low volume batch production, the ability to iterate a dozen designs in a single day or produce a revised prototype during a design meeting.

Wide ranging technology

Production and tooling solutions on show this year number in the thousands, including workholding, industrial storage, consumables and a myriad of others. Specialist tooling vendor ITC returns with its range of high precision cutting tools. Workholding specialists exhibiting this year include AMF Andreas Maier and Roemheld. YMT Technologies will highlight its comprehensive range of tooling, including rotary tables, vices and spindle tooling.

Blum Novotest will be showing the latest software advances for its recently introduced Digilog probe series designed to bring the integration and everyday use of fully automated solutions within reach of even the smallest of CNC machining companies.

Returning to Southern for the third successive year, E-Max Systems will share some innovative developments for its ERP and MRP software, designed specifically for manufacturing and engineering businesses. New features include new financial functionality such as Making Tax Digital and standard costing, as well as a new speeds and feeds calculator.

Strong seminar programme

This last product illustrates another important role that the show fulfils; that of providing an extremely valuable opportunity to keep up to speed with the latest developments in the engineering business, courtesy of the show’s excellent free seminar programme.

Over 30 sessions take place over the three days in two dedicated lecture theatres, considering a wide variety of subject matter, from technical topics such as CE Marking, 3D printing and Industry 4.0, to more management-orientated ideas including best practice, implementing Lean and how to market technical products effectively.

The event will once again be working together with a number of leading industry organisations, which will be sharing know-how through the seminar programme. These include the Farnborough Aerospace Consortium, alongside national bodies including Composites UK, NetComposites, the Confederation of British Metalforming, the GTMA and the British Gear Association.

Also taking part this year is Locate in Kent, an organisation offering a broad range of expert services and help to businesses aiming to settle within the region. A complete list of sessions and the all-important pre-registration form will be available online at the show’s website in the New Year.

Farnborough International Conference and Exhibition Centre offers complimentary car parking for 3,500 vehicles and is well-served by road and public transport links. A regular free shuttle bus service operates from both of Farnborough’s mainline railway stations directly to the exhibition.

The venue itself provides a high standard of facilities including a complimentary WiFi service in the foyer area as well as high-quality catering outlets. Admission to the exhibition is free of charge.

Southern Manufacturing & Electronics 2020 www.industrysouth.co.uk