Southern Manufacturing 2020: exhibitor promotion

PES continues its rundown of manufacturing technology exhibitors who be found at Farnborough Exhibition Centre from February 11th-13th.

PES continues its rundown of manufacturing technology exhibitors who can be found at Farnborough Exhibition Centre from 11-13 February.

Read more of PES’s coverage of Southern Manufacturing 2020 here.

Automation takes centre stage

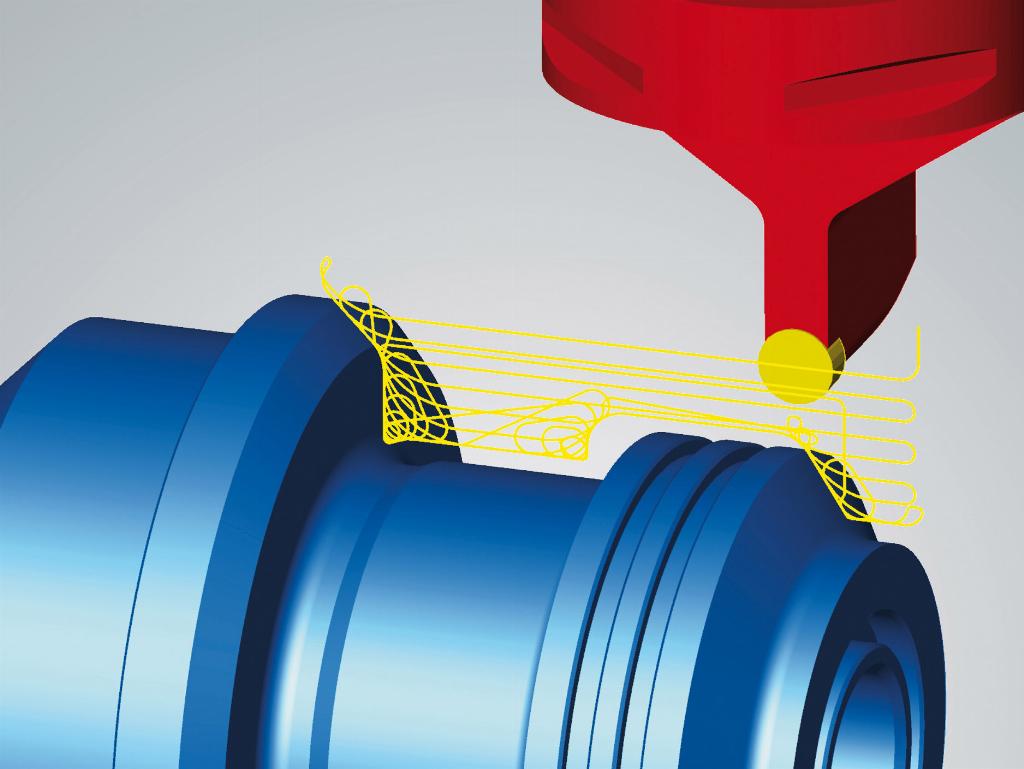

XYZ Machine Tools’ attendance at the Southern will focus on automation, 5-axis machining and the latest development of the ProtoTRAK control system, including XYZ’s robot-based automation cell Robo-Tend, which will be highlighted.

This modular and mobile robot automation system is designed for use with XYZ vertical machining and turning centres fitted with Siemens controls. For the exhibition the system will be demonstrated attached to an XYZ 750 LR vertical machining centre.

Robo-Tend brings automation within the reach of traditional subcontract engineering businesses. The robot is equipped with a camera vision system and is fully compatible with the Siemens ShopMill and ShopTurn controls used on XYZ’s VMCs and turning centres.

In line with XYZ’s philosophy of making machine control straightforward, Robo-Tend’s interface has been developed to make programming the automation process as simple as possible. The result is fast and efficient automation that is affordable for all, with payback possible in just a few months of operation, calculated if purchased outright – or the option of finance from £2/hour is available.

For those looking for full, simultaneous 5-axis machining the XYZ UMC-5X will be demonstrated. This cost-effective machine has as standard a direct drive 90rpm table configuration, which when tilted 90° towards the rear (component facing forward), there remains 500mm of Y-axis travel forward of the table surface, allowing larger workpieces to be machined.

Its gantry-type design adds greater rigidity and performance, while C-axis rotation via a direct drive, low maintenance, high torque motor, gives 90rpm rotational speed; with ±120° on the tilting A-axis, while 600mm axis travel in X and Y (500mm in Z) maximise use of the 600mm diameter table. Standard spindles are inline direct drives with 35kW of power and either 12,000 or 15,000rpm. An option to go to a 25kW, 18,000/24,000rpm motorised spindle is also available.

The latest version of XYZ’s ProtoTRAK control system will be shown on an XYZ RMX 3500 bed mill and an XYZ RLX 355 ProTURN lathe. The latest generation ProtoTRAK control, the RX retains all the features that make ProtoTRAK popular with thousands of customers, but with the addition of a host of new features and benefits. Central to the new control is its 15.6” touchscreen that puts all of the existing advantages, along with more machining information, at the users’ fingertips.

Combining the touchscreen with DXF capability removes any requirement for a mouse to interact with editing of programs. The touchscreen also adds the familiar actions of pinch to zoom, twist to rotate making it far more intuitive and allows closer inspection of the part program prior to machining.

The new control will be demonstrated live on the stand to highlight its ease-of-use and time saving benefits.

XYZ Machine Tools

www.xyzmachinetools.com

Stand J210

Looking ahead with lasers

Tubes and profiles are used in many applications from mechanical engineering and system construction through to the furniture industry and at this year’s show, manufacturing technology company Trumpf will be focusing on how its TruLaser Tube machines are opening up new design possibilities in this sector.

As a leading foremost developer and manufacturer of industrial lasers, Trumpf offers manufacturers a wide choice of solutions for tube and profile processing.

If high speed cutting is a priority, Trumpf’s solid state laser machines provide a distinct advantage, especially when cutting thin sheet. And the fibre models build on this solid-state capability to ensure short processing times for the widest possible range of parts. The Trumpf TruLaser Tube 7000 Fiber for extra-large tubes is a good example.

With this flexible high-end machine, manufacturers can cover a broad range of parts and investigate new areas of application for laser tube cutting. The machine cuts tubes and profiles with a diameter of up to 254mm and wall thicknesses up to 10mm for mild steel.

The second focus process on the Trumpf stand is bending. The company now has an extensive portfolio of Trumpf bending machines that incorporates the TruBend 7000 series for the high-speed bending of small parts to the TruBend 3000 series and 5000 series for processing medium and large-scale parts with a press force of up to 3,200kN. The TruBend Center series takes automated bending to the next level of productivity.

Visitors to Southern Manufacturing will also learn how Trumpf Smart Services such as the Easy Order, Service app and Remote Service can simplify their daily work. They will also be able to explore the advantages of the MyTrumpf customer portal.

Trumpf

www.trumpf.com/en_GB

Stand D230

Home-grown 5-axis technology

Yamazaki Mazak will be taking its new UK-made, fully-simultaneous 5-axis machining centre to Southern Manufacturing this year.

The CV5-500 has been entirely designed and built at Mazak’s European Manufacturing Plant in Worcester, specifically for machine users engaged in, or aspiring to, 5-axis machining. The machine, which is being brought to market at a highly competitive price point, has a high-rigidity bridge construction with a fully supported trunnion table, which delivers an accurate and extremely compact machining solution.

It is equipped with a new versatile 12,000rpm spindle, capable of a peak performance of 18.5kW and 119.4Nm, making it highly suitable for a wide range of materials. The machine benefits from a compact footprint, making it ideal for smaller machine shops, and it can also be easily automated with a side-loading door and robot interface. The CV5-500 is equipped with SmoothX CNC, Mazak’s specialist 5-axis version of its Smooth Technology.

Alan Mucklow, managing director UK & Ireland sales division at Yamazaki Mazak, comments: “The CV5-500 is set to become one of the flagship machines produced at our manufacturing facility in Worcester. Crucially, customers were heavily involved in the R&D process to ensure the end product is equipped to deliver standout performance across a range of vertical markets, including both the subcontract and autosport sectors.

“The bridge construction promotes both high rigidity and high accuracy, while easy integration with ancillary automation equipment can be achieved by a new side-loading door. Ultimately, we feel this is the most compact, fully simultaneous 5-axis machining centre on the market, with a price point that offers a real opportunity for those with the ambition to move into more complex machining processes.”

On Southern Manufacturing, he adds: “High-mix work – both in terms of component type and sector – remains the order of the day for the UK subcontract market looking ahead to 2020. However, we feel that more and more companies are looking to either expand or commit to their first investment in 5-axis machining over the coming months.

“The CV5-500 is perfectly placed to meet this appetite and there is no better place for subcontractors to see the machine for themselves this winter than at Southern Manufacturing.”

For more information on the CV5-500, please visit: https://www.mazakeu.co.uk/cv5-500

Yamazaki Mazak

www.mazakeu.co.uk

Stand J220

Comprehensive software solutions

NCSimul and Fasys will be on show for the first time at Southern Manufacturing exhibition as part of Hexagon’s production software portfolio.

The latest releases are being demonstrated on the company’s stand, along with Hexagon’s range of CAD/CAM and production control packages designed specifically for different manufacturing methods.

Helping manufacturers bring their factories in line with the Industry 4.0 philosophy of smart production, Hexagon’s solutions fully support data-drive smart factories. They mesh seamlessly with each other to harness data which improves processes from design and engineering through to production.

It is expected that visitors to the stand will be particularly interested in the latest additions to the Hexagon production software business, NCSimul and Fasys.

Continuing Hexagon’s ethos of powering a successful digital ecosystem, NCSimul manages the complete machining process from the NC program to the machined part, including automatic G-code reprogramming and powerful G-code simulation.

The current release contains a number of important enhancements to both high-end machining verification and to the module which automatically converts CAM and NC programs to different machines.

And Fasys supports the entire manufacturing workflow from conception to the final product, including design and planning through to NC programming, during tool presetting or at the machine, by providing relevant production information and securely integrating all the systems involved.

Specialists will also be on hand during the show to guide visitors through the range of Hexagon’s CAD/CAM, MRP and MES systems.

These include EdgeCAM, the leading production CAM solution combining sophisticated toolpath generation with seamless CAD integration. Visitors to the stand will see a number of updates in the latest version, including toolpath associativity in the Face Mill cycle, extension to the Parallel Lace toolpath, and enhanced additive undercutting. Also, the optional CAD for CAM Designer module has now replaced Part Modeler.

Other manufacturing software solution from Hexagon include:

Visi for the mould and die industry which enhances the progressive die design processes, along with containing enhancements for the Reverse module;

WorkNC 2020.1’s latest Roughing with Advanced Toolform technology allows the milling process to deliver a more accurate roughing stock, eliminating imprecisions which were characteristic to the traditional parametric toolpath calculation;

Radan, Hexagon’s sheetmetal solution which now allows for an endless nesting workflow;

Workplan MES, a solution designed to support management by automating business processes, providing control from creating quotes and sending order confirmations, through to the final invoicing;

Javelin 2020.1 looks at items of new and enhanced functionality which have been added to nine well-used areas of the MRP and production control software, including Works Orders, Bill of Materials, Purchasing, Advanced Scheduling, and Traceability; and finally;

Worksxplore, Hexagon’s powerful high-speed CAD viewer and analyser.

Hexagon Production Software

www.hexagonmi.com/products/production-software

Stand J240

Tooling excellence

MSC Industrial Supply Co. (MSC), a national supplier of metalworking and maintenance, repair and operations (MRO) products and services, is exhibiting at Southern Manufacturing where it will showcase its range of tooling products, engineering expertise and market-leading inventory management solutions.

MSC will demonstrate how its advanced inventory management solutions deliver visibility, flexibility and control – reducing costs, and improving productivity and profitability. With experts on hand, MSC will explain its processes and services that assist with everything from choosing the right inventory option, to tooling and product selection and application recommendations.

The business takes pride in its ability to understand customer needs and create bespoke vending solutions to help deliver significant and sustainable competitive advantage, underpinned by industry-leading customer service and engineering support.

Dave Darby, managing director at MSC, said: “Southern Manufacturing and Electronics provides an exciting platform for us to showcase our sector knowledge, engineering expertise and our range of inventory management solutions and services.

“It is the combination of our unique services and deep technical expertise that sets us apart from our competitors, enabling us to provide a complete solution for UK manufacturing businesses, helping them drive down costs, deliver process efficiencies and become more profitable.”

MSC

www.mscdirect.co.uk

Stand J180