Welcome return for Southern Manufacturing showcase

Southern Manufacturing & Electronics makes a warmly anticipated return to Farnborough from 8-10 February 2022.

The show’s eagerly-awaited revival comes at a time of unprecedented challenge for the manufacturing sector. The much hoped for light at the end of the COVID tunnel still seems a long way off.

As if that wasn’t enough, the after-effects of Brexit continue to bite in the shape of skills shortages and supply chain woes, and energy costs that seem to be barrelling ever-upwards at a shocking pace. All the more reason, then, to cheer the valiant efforts of those in the engineering sector determined to get back to face-to-face business and overcome every obstacle.

The announcement of the show’s return was greeted with hearty enthusiasm by its many long-term supporters, the majority of whom, admirably, appear to have weathered the turbulent conditions of the last 20 months and are now eager to pitch their stalls once again at one of the UK’s longest running and largest annual engineering shows.

With just a few stands left to sell, the organiser expects the 20,000m² Farnborough International Exhibition Centre to be fully booked by the time the show opens, and is hopeful of matching 2020’s (pre-COVID) record-breaking attendance of over 9,250 visitors.

High-tech solutions

With a full complement of exhibitors on board, the show’s trademark diversity of participants will return in its full glory for 2022, with a wide array of high-tech automation, mechanical and electronic components, tooling, industrial hardware, business and subcontract services from all over the UK, continental Europe and beyond.

Uppermost in the minds of many visitors though, will be their search for answers to skills shortages, rising energy costs, supply chain difficulties and the challenges of cross-border business – all areas that Southern Manufacturing 2022 and its diverse exhibitor base are seeking to address.

Automation is, not surprisingly, high on the agenda for many as they seek to mitigate the shortage of skilled labour and drive efficiencies. Southern Manufacturing 2022 offers some interesting options.

Collaboration between man and machine is seen as a crucial step forward in workshop productivity. Design & Automation (DAS) Solutions will be demonstrating an example of human-machine collaborative working on its stand (C310), at Southern 2022 using a MELFA ‘Assista’ collaborative robot (cobot), supplied by Mitsubishi Electric Automation Systems UK.

DAS creates custom cobot solutions for a variety of applications, recent examples being a tooled Grimm linear to a cap feeding system for a UK-based biotech automation company and a project to provide a high-performance powered gantry system.

A host of familiar names in the metalworking world will also be at the show including: XYZ Machine Tools; 1st Machine Tool Accessories; Dugard; Mills CNC; CGTech, Aberlink, MSC Industrial Supply Co.; MIE Solutions and Mitutoyo to name just a few.

Subcontracting on show

Alongside the latest machinery and tooling, subcontract services are the other major aspect of Southern which draws many visitors each year. Here again, many familiar faces will be encountered such as Jenks & Cattell, Orbital Fabrications, Barlow Sheet Metal, MJ Allen and many more.

Glenrothes-based Fife Fabrications celebrates its 50th anniversary at Southern Manufacturing 2022. Some of the more niche service providers include Hardcoating Technologies, extending tool life through the use of PVD coatings as part of its regrind and recoat service.

Together with the exhibition and demo spaces, the ever-popular free seminar programme will return for 2022 in a socially-distanced format. Subjects tackled include energy reduction, new technology, innovation, supply chain and business strategy, together with a look at the latest industrial and post Brexit regulations.

While the spectre of COVID still hangs over our heads, safety will of course be a vitally important consideration. Thankfully, its location and status as one of Europe’s most modern venues, goes a long way to help ensure Farnborough International is as safe an environment as possible. There's free parking for 3,500 vehicles on site and easy road access from the M3.

For those arriving by public transport, a dedicated free shuttle bus service connects directly the show with both of Farnborough’s railway stations. The venue itself is equipped with the latest filtered fresh air ventilation and all infection control measures will be in place for the duration. Venue facilities such as a free WiFi service and on-site catering means it’s not necessary to venture outside the show once you are safely ensconced inside.

Admission to the exhibition is free of charge. To register visit the show website.

Southern Manufacturing & Electronics 2022

www.industrysouth.co.uk

Exhibitor focus

Turned up turning capability

XYZ Machine Tools’ attendance at the Southern Manufacturing & Electronics 2022 will provide UK exhibition visitors with the first sight of the brand new XYZ SS 65 twin/sub-spindle turning centre, which was recently added to XYZ’s range. The XYZ SS 65 breaks new ground, says the firm, being its first foray into multi-spindle turning centres, a move driven by demand from customers looking for increased productivity and reduced spindle downtime.

The XYZ SS 65 has a high specification and build quality, yet is highly competitively priced. It is equipped with a 16.5kW, 4,000rpm, main spindle, 6mm bar capacity, with 200mm diameter main spindle chuck complemented by a 150mm chuck on the 11kW, 5,000rpm, sub-spindle, which has a 52mm bore.

A German-built Sauter 12-position turret has live tooling at every station, with 100mm (±50mm) Y-axis travel. Contouring is facilitated by the C-axis on both spindles which are equipped with a brake to allow substantial milling cuts to take place.

Maximum turned diameter is 380mm and the Z-axis travel is 520mm, providing a significant working envelope – all built around a 30° slant-bed base with linear ways for high performance positioning. Control is via the Siemens 828D ShopTurn 15-inch touchscreen control, which can be enhanced with the optional Siemens offline programming and CAD reader software if required.

XYZ contends that the timing of its launch of a twin/sub-spindle turning centre with live tooling and Y-axis is highly appropriate as companies bounce back from the restraints of the pandemic while facing the challenge of finding skilled labour. The ability to machine parts in one-hit, thereby reducing part handling and idle time, it says, will enable machine shops to maximise productivity and spindle up-time while making use of available labour.

XYZ Machine Tools

https://xyzmachinetools.com

Stand J210

Measurement made easy

Two CMMs will be the highlight of this year’s Aberlink stand at Southern Manufacturing. The Extol and the Axiom both use the latest release of the Aberlink 3D CMM inspection software.

The whole philosophy of the CMM software is to make measurement easy. The robust and reliable Extol CMM can run 24/7, positioned next to a machine tool, in a manufacturing cell, or used in a dedicated inspection area. It automatically verifies the part quality of critical components. Used in conjunction with the Aberlink automation interface, the Extol CMM can run unmanned and autonomously.

The Axiom too CMM is the company’s bestselling range of coordinate measuring machines. The lightweight construction and air bearing design allows the CMM to be fast and accurate in almost any thermally dynamic environment. Measuring volumes are available from 600 to 1,500mm.

Aberlink

www.aberlink.com

Stand K205

Automation answers

The theme at this year’s show for 1st Machine Tool Accessories is ‘Don’t wait to automate’. The workholding and automation equipment specialist will show a sample of products for raising output and maximising return on investment from machine tools.

Products showcased will include the Kitagawa QJR with quick-change chuck to reduce set-up times and the Kitagawa BR for improved repeatability with T-Nut Plus (the new chucking standard).

Visitors can also see V-Tech’s zero-point plates for quick-change pallet systems, Chick Workholding’s multiple component clamping for long machine running times, the Swift-Klamp for automated loading/unloading on machining centres, 4- and 5-axis Kitagawa rotary tables, short, long and multi-spindle Iemca bar feeds and for automating loading/unloading or both turning and machining centres, Halter robots.

1st Machine Tool Accessories

www.1mta.com

Stand G205

Heavy duty tube bending

Tube bending specialist AMOB UK will unveil the latest version of the eMOB Super Heavy Duty series. These electric tube bending machines have the ability to bend tubes up to 225mm in diameter.

Visitors can view a fully-electric mandrel bender from the range and talk to experts about forming technology. The company claims to offer one of the biggest ranges of specialised equipment for the tube and pipe bending industry worldwide from simple machinery, to complex fully electric CNC powered systems.

The manufacturer specialises in mandrel bending, rotary draw bending, and section bending as well as designing and developing products for bespoke applications in a range of industries, including automobile, shipping, offshore installations, aeronautics, chemical, construction and power.

AMOB

https://amob.co.uk

Stand G210

Making a mark

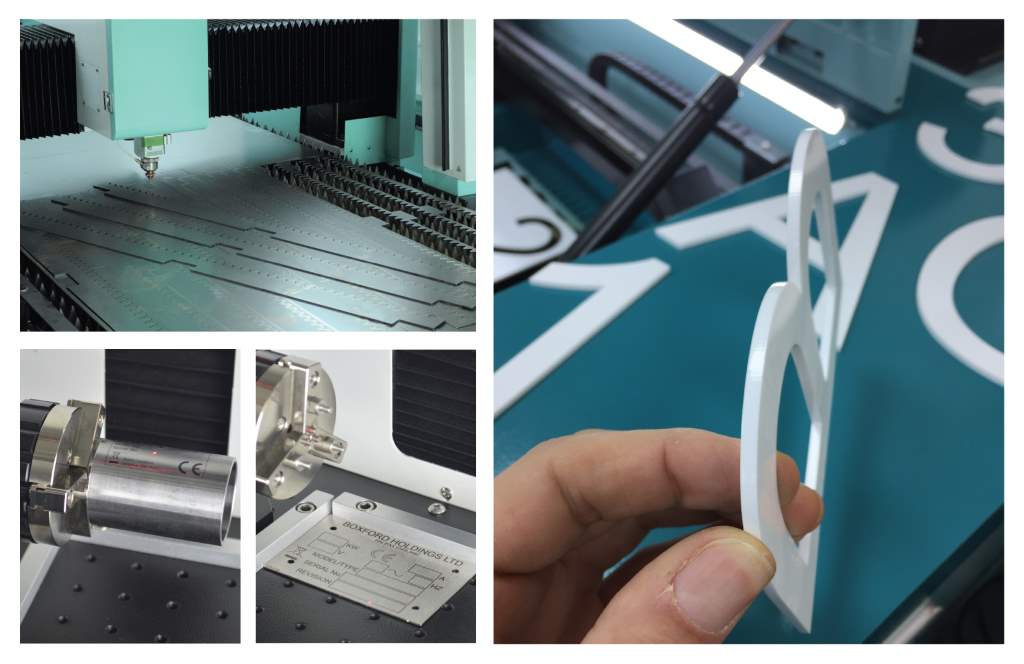

Boxford will highlight its range of professional, affordable and reliable laser cutting, engraving and CNC machines. There will be live demonstrations using a selection of the company’s compact laser cutting, engraving and marking equipment.

Machines capable of cutting and engraving a range of materials, including metals, wood, plastics, paper, card, foam, rubber are available and a team of experts will be on hand to answer any questions raised during the show.

Boxford

www.boxford.co.uk

Stand L110

Top brands for manufacturing

Derbyshire-based Carfulan Group will showcase its four advanced machinery brands at the show: OGP, Vicivision, Zoller and Stratasys.

OGP UK and Vicivision UK specialise in metrology equipment and turned part measurement; Zoller UK is an expert in the measuring, inspection and fast presetting of machine tools. It facilitates industry 4.0-ready, interconnected floors where networked data and automation ensure a level of efficiency for rapid returns on investment.

Additive experts SYS Systems pioneered fused deposition modelling. Its industrial-grade polymers and commitment to controllable quality ensures that Stratasys machines produce repeatable, reliable parts.

Cafulan Group

www.carfulan.com

Stand J200

Diverse machining options

Dugard Machine Tools will be introducing three machines at the show: a Kitamura vertical machining centre; a SMEC turning centre and also a Hanwha sliding head turning centre.

The Kitamura MedCenter5AX 5-axis vertical machining centre is a compact and versatile machine. With X- Y- and Z-axis travels of 254 x 330 x 330mm over a 170mm diameter table, the machine incorporates a 30 to 30,000rpm spindle with an HSK-E40 spindle taper, connected to a 40-tool ATC that can change tools in just 1.5 seconds. Additional highlights include a rapid traverse of 60m/minute and table rotation of 200rpm on the A-and C-axes.

Linear and rotary scales, 67 million pulse encoder technology and 16mm pitch ballscrews make the Kitamura MedCenter5AX a precise and productive proposition. With a positional accuracy of ±2µm across the full stroke and repeatability of ±1µm, it is also one of the most accurate machines on the market.

Dugard will be demonstrating one of its most popular machine tools – the SMEC SL2000ASY turning centre. Built upon the foundation of a single-piece Meehanite casting that is heavily ribbed with a torque tube design, box way slideways are used throughout the SMEC range, resulting in excellent vibration dampening and thermal displacement characteristics. This combination permits powerful heavy-duty cutting that ultimately enhances surface finishes, tool life, component quality and productivity.

The robust machine hosts a 6-inch chuck (8 inch optional) with a 650mm swing over bed capacity that allows a maximum machining diameter of 395mm and a maximum turning length of 490mm. This spacious work envelope ensures the robust machine caters for the diverse demands of the industry. The SMEC SL2000ASY has a bar capacity of 52mm (optional 68mm) and a powerful 18.5kW spindle motor that combine to enable heavy-duty manually loaded or automatically barfeed machining of relatively large diameter parts. For manufacturers that demand one-hit machining, the SL2000ASY also includes a sub-spindle.

For the machining of smaller turned parts, Dugard will be exhibiting the compact Hanwha XD10 sliding head turning centre.

The Hanwha XD10 at the show will be driven by a FANUC CNC interface. A Siemens control system is also available. The machine incorporates the facility to rapidly switch from guide bush to non-guide bush operation. With a 10mm bar capacity and a 15,000rpm 2.2/3.7kW main spindle motor that is complemented by a 10,000rpm 0.5/1.1kW sub-spindle, the Hanwha XD10 offers precision and flexibility to suit any small part turning shop.

Dugard

www.dugard.com

Stand J220

Optimised simulation and verification

CGTech’s Vericut is a recognised industry leader in CNC simulation, verification and optimisation to prevent errors and verify entire NC manufacturing processes end-to-end.

Vericut 9.2 increases productivity and sustainability with improvements to collision checking and overall performance, as well as enhanced support for ‘intelligent’ cutting tools with cutting performance information and detailed tool reporting.

Also added is a 3DLive interface to import GDML files, enabling users to quickly and easily create realistic digital machines and add other moving components (rotary tables, articulating heads, fixtures with moving clamps, etc.) for more realistic simulation.

Vericut 9.2 also provides important advancements in optimisation and monitoring machining processes. Vericut Force is a physics-based NC program optimisation module that makes changes to the program based on the specific stock material, cutting tool properties, and machining conditions encountered during simulation. Force optimised program feed rates maintain an ideal constant chip thickness as much as possible, while simultaneously limiting excessive cutting forces or spindle power requirements.

Gavin Powell, CGTech technical director, comments: “With Vericut 9.2’s improvements to optimisation, cutting graphs and ability to import cutting tools with machining intelligence, this newest version gives users more information and insights into machining processes.

“Users can view combinations of Cutting Conditions and Force Conditions, and compare the original versus optimised values in new Graphs and Tool Use windows. These windows can also be docked in Vericut’s desktop for constant monitoring of machining conditions in real-time during simulations.

“This visibility allows them to spot potential flaws and inefficiencies in machining, so they can adjust their strategies or optimise them before running the programs on their NC machines.”

CGTech

www.cgtech.co.uk

Stand C215

Streamlined production planning

MIETrak Pro is an industry specific, complete enterprise resource planning (ERP) software solution for all manufacturing industries designed to streamline operations across the entire workflow process and provide maximum efficiency along with an immediate return on investment (ROI).

The software is simple to install, use and implement and includes advanced features such as cost control, MRP, scheduling, reporting, quoting, inventory control, real-time tracking and more.

MIE Solutions

https://mie-solutions.co.uk

Stand F210

Technology trio

Laser Lines will exhibit examples and live demonstrations of three new additive manufacturing technologies, namely saturated absorption fabrication (SAF), stereolithography (SLA) and P3 polymerisation, together with DyeMansion post processing technology to create a full end to end manufacturing solution.

Other highlights of its range of lasers, laser systems and accessories include Synrad COâ‚‚ lasers in the 10 to 400W range, Datalogic laser markers, DPSS, fibre and COâ‚‚ laser technologies for integration or within the company’s range of standard and bespoke laser marking, high power diode sources and pulsed YAG welding and cutting systems.

Lasers for industrial processes such as marking, engraving, drilling, welding, soldering, brazing and cladding are also available. The company will be demonstrating some of its smaller laser welding and laser marking equipment.

Laser Lines

www.laserlines.co.uk

Stands E150/L140

Printed component advances

Bowyer Engineering will launch its in-house designed 3D printer, Orochi.

The system is designed to overcome the limitations of existing 3D printers in the manufacture of components and assemblies used in applications such as on-wing inspection equipment manipulators designed to place sensors and probes in difficult to reach places.

The new printer features twin heads that can print singularly or in ‘copy and mirror’ mode. Each head has four interchangeable tools and the machine is optimised for reliability, low maintenance and low ongoing cost of ownership. Applications include printing, milling, drilling, laser engraving and inspection.

Bowyer Engineering

https://bowyerengineering.co.uk

Stand E255

Multiple metrology options

Nikon Metrology offers a broad range of metrology solutions for applications ranging from miniature electronics to the largest aircraft.

The company’s innovative measuring and precision instruments contribute to a high-performance design-through-manufacturing process that allows manufacturers to deliver premium quality products in a shorter time.

Nikon Metrology

www.nikonmetrology.com

Stand K220