Upgraded aerostructure machining

As a global technology leader in the manufacture of high-precision machine tools for milling, turning, boring and grinding workpieces in metallic, composite and ceramic materials, the Starrag Group is constantly re-evaluating and enhancing its comprehensive product range. A case in point are a number of upgrades made to the company’s Ecospeed and Ecoforce machines. PES takes a closer look.

As a global technology leader in the manufacture of high-precision machine tools for milling, turning, boring and grinding workpieces in metallic, composite and ceramic materials, the Starrag Group is constantly re-evaluating and enhancing its comprehensive product range. A case in point are a number of upgrades made to the company’s Ecospeed and Ecoforce machines. PES takes a closer look.

The enhancements made to Ecospeed and Ecoforce machines – used predominantly for aluminium and titanium aerostructural component machining respectively – are designed to improve cutting performance in terms of both reduced cycle times as well as the highly consistent production of high-quality components.

The developments include: a more powerful spindle – 150kW for the Ecospeeds – for even higher productivity; enhanced software routines, for example, for optimised chatter control and adaptive jerk feed control on both Ecospeeds and Ecoforces; and new pallet options on the Ecoforce Ti 9 and Ti 13 models to accommodate ever-increasing workpieces sizes, particularly in structural aerospace components.

Starrag is also promoting significant cost benefits through the use of MQL (minimum quantity lubrication) as opposed to conventional flood coolant, with users obtaining at least threefold savings primarily through eliminating the need for coolant-related maintenance and recovery systems.

The use of MQL rather than conventional cutting fluid (on any machine in Starrag’s comprehensive range) is heavily promoted for aluminium machining and it is suggested that if MQL is used at 100 ml/hour, 16 hours/day for six days a week and 50 weeks of a year, the total operating cost of €10,000 seriously undercuts the €30,000 spent on conventional coolant year after year. In addition, the difference in capital investment for the different systems is even greater.

The machines’ continual evolution, underpinned by Starrag’s mantra of ‘Engineering precisely what you value’, is the result of the constant investigations by Starrag’s expert product specialists and engineering teams into machine attributes and process improvements that will enhance overall machine performance in the most cost-effective manner.

Importantly – and complementary to utilising the latest machining technologies – Starrag also offers exemplary levels of customer service, based on a team of customer-facing service specialists, as well as dedicated onsite Starrag engineers for appropriate installations. The net effect is that users (of standalone machines through to minimally-manned flexible manufacturing systems) enjoy guaranteed 95% uptimes.

Focused on aluminium

The Ecospeed variants built to date, with pallet sizes from 1m by 1m to 2.5m by 22m, are renowned for their excellent cutting performance in aluminium. For instance, an Ecospeed can convert a 4,100kg aluminium billet into a 123kg complex structural wing part in less than 20 hours when the machine is running at a maximum cutting volume of up to 10,000cm³/minute.

Now, according to Starrag, such achievements can be further enhanced with the use of a 150kW HSK A 63/80 spindle (which complements the existing 80 and 120kW units) plus increased drawbar pressure to offer a metal removal rate of up to 12,000cm³ at speeds of up to 30,000rpm with 18mm depth of cut.

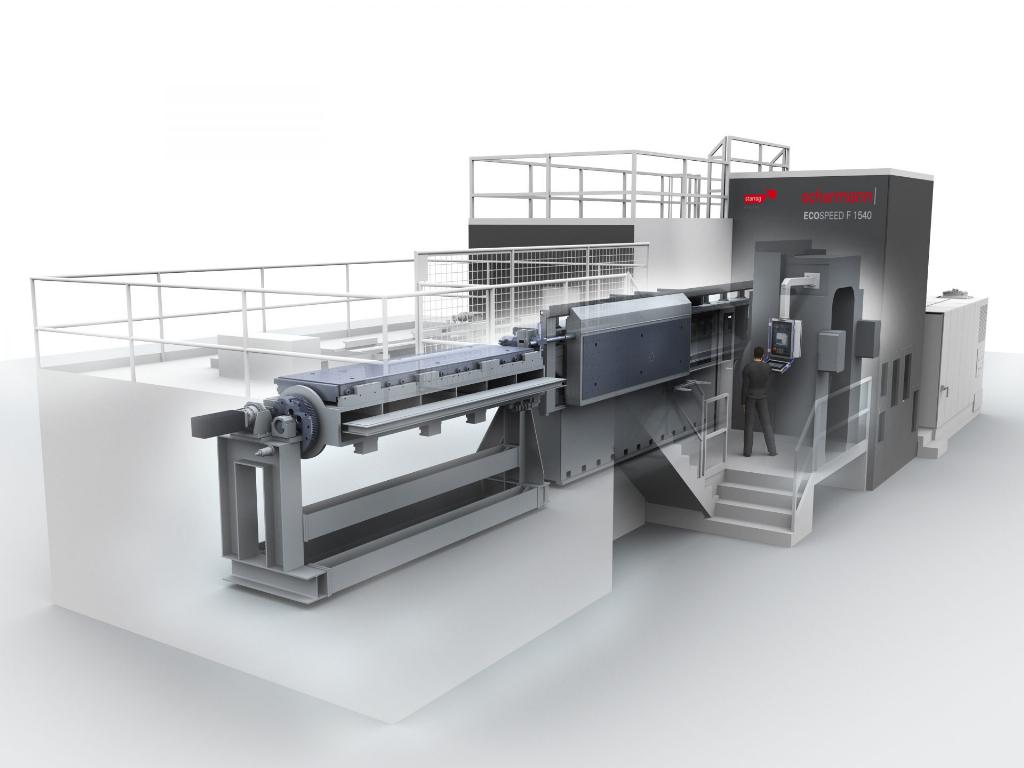

Another new Ecospeed development is the introduction of a ‘standard’ F1540 model which is designed for installation onto a flat floor without the need for a complex foundation. This model comes with a two-position automatic pallet changer, but it is also possible to integrate the model into a flexible manufacturing system, either from the outset or conversion at a later date.

Other developments for the Ecospeed F series machines include the use of four drives for all sizes (instead of three on the 2 x 4m version) on the worktable, for manoeuvring fixtures/workpieces, alongside an upgraded drive train which enables higher feed and acceleration rates improving these attributes by more than 20%.

Hardware and software: better by design

Meanwhile, the new Ecoforce Ti 9 and Ti 13 (900 or 1.300Nm torque) machines specifically for titanium machining, represent a coming together of proven Starrag components such as machine sub-assemblies and spindles for the effective and efficient rough and finish machining of larger forged workpieces weighing up to 12,000kg on pallets of 4 to 6m long and 2m x 2.5m wide.

Importantly too, the ability to use shorter tools promotes higher stiffness and more stable cuts with high metal removal rates. For example, roughing a Ti 6 Al 4V workpiece using an 80mm diameter porcupine cutter at a surface speed of 75.5m/minute, a feed rate of 240mm/minute and a 100mm depth of cut at 300rpm spindle speed, an Ecoforce can achieve an impressive metal removal rate of 816cm³/minute.

Effective spindle monitoring has always been a core functionality of Starrag’s Integrated Production System (IPS), a modular digital platform that offers users a suite of functionality to meet individual tasks via the machines’ HMI (Human Machine Interface).

These include: Cloud-based solutions that analyse and optimise processes; the Machine Production System that monitors production in real-time and protects the machine against incorrect operation/collisions; and the Machine Qualification System that informs about machine condition and, when necessary, displays the appropriate maintenance instruction(s).

Vibration and chatter monitoring functionality are included here and while the former automatically identifies highly unbalanced tools and peak vibrations, chatter monitoring automatically detects potential dangers to process stability.

In addition, the machines’ Siemens CNC’s integrated inertia estimator permits adaptive jerk and acceleration settings, with jerk being automatically set according to actual payloads – which means faster cycle times as the workpiece becomes lighter during the machining process.

The machines’ software now also incorporates functionality embracing compensation strategies for tackling the effect of ambient temperature changes as well as the heat created by the cutting process (especially on aluminium workpieces) on component length and machine geometry.

Start with the component

All these enhancements are part and parcel of Starrag’s continual quest to present cost-effective solutions to customers’ problems, as managing director Dr Bernhard Bringmann emphasises: “The starting point for every Starrag solution is the component, not one of our machines. We vary machine configurations and machining concepts to determine the overall effect on cycle times; pushing everything to the maximum to develop an all-embracing solution that is specific to each workpiece.”

He adds: “We are not in the market to sell ‘standard’ machines; we strive to continue to be the application champion on specific parts required in either low or high volume. Our customers have to be competitive and, likewise, we have to remain focused on delivering cost-effective and efficient solutions time after time.”

Starrag UK www.starrag.com