Subcon 2023: Suring up the supply chain

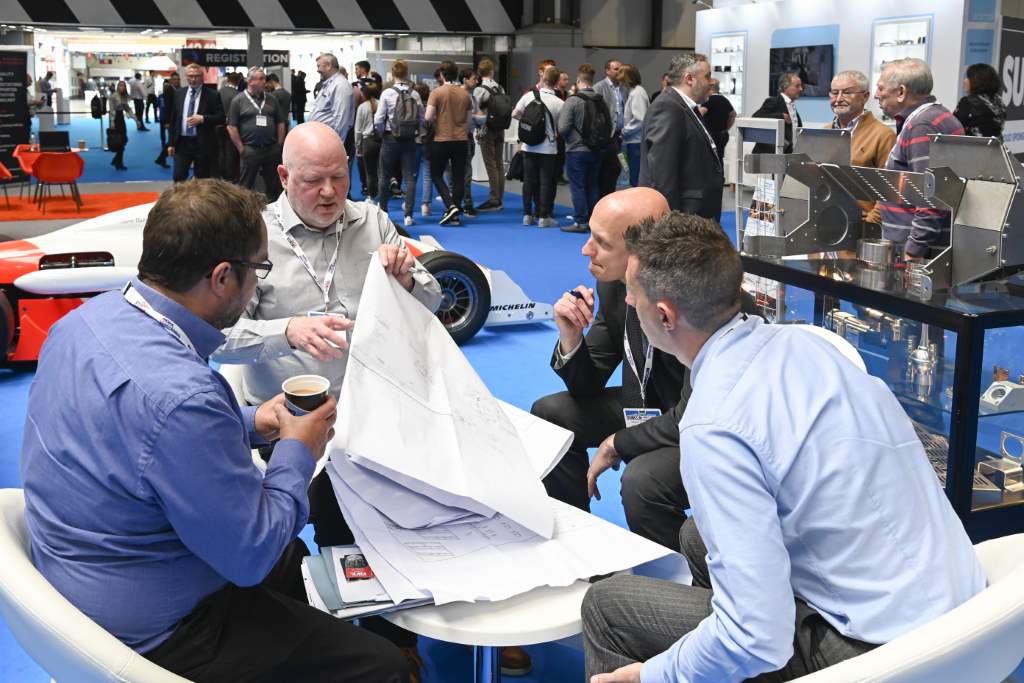

Subcon is back with a bang for 2023, bringing together the full manufacturing ecosystem for companies to source, subcontract, benchmark and learn all under one roof. PES reports.

Combining the UK’s biggest and longest-running subcontract manufacturing supply chain exhibition with more than 20 hours of free-to-attend conference sessions, Subcon is engineered to help futureproof your business.

More than 200 solution providers representing the best of British manufacturing engineering capability, alongside a wealth of market-leading international suppliers, will be present to help businesses optimise their supply chain strategy and keep costs down.

Thousands of new products and innovations will be on display across the full range of advanced engineering technology, systems and services – from additive manufacturing and metrology solutions to frictionless bearings, cables and controls, and everything in between. This is a show geared to help companies increase capacity, optimise productivity, improve flexibility and remain competitive.

Conference sessions to educate, inform and inspire

New for Subcon 2023 are two conference theatres. Collectively, they will convene dedicated conference streams for two days of high-quality, case study-led discussions about hot technology and business process trends.

Two theatres will run in parallel, a dedicated Supply Chain Theatre in conjunction with Machinery Magazine and a second theatre co-led by The Engineer and Manufacturing Management magazine.

A cherry-picked line-up of industry leaders are set to deliver insightful sessions covering automation; cybersecurity; energy Storage; Net Zero; recruitment & retention; supply chain resilience and much more.

Conference highlights

Five key sessions taking place at Subcon 2023 (all are subject to alternation):

- Theatre 1: Thursday 8th June: 10:35am – 11:05am

Are manufacturers ready for the challenges of moving to a Net Zero world?Keynote by Professor Paul Monks, chief scientific advisor to the Department for Energy, Security and Net Zero

- Theatre 1: Wednesday 7th June: 11:10am – 11:50am

UK recovery: What are the new markets and how accessible are they?Panel discussion led by Mike Wilson, chief automation officer at the MTC

- Theatre 1: Thursday 8th June: 11:55am – 12:35pm

Reimagining the skills shortage: From education to employmentPanel discussion with expert insights from Innovate UK KTN, MTC and Sempai

- Theatre 2: Wednesday 7th June: 2:10pm – 2:45pm

Bringing home the supply chainPanel discussion on the logistics of reshoring led by Aristides Matopoulos, professor of supply chain design at Cranfield University

- Theatre 2: Wednesday 7th June: 11:55am – 12:35pm

Why should additive manufacturing be used in designing your supply chain?Panel discussion with expert insights courtesy of Digital Manufacturing Centre, Prototal and AM-UK and CECIMO trade associations

EXHIBITION SPONSORS

Bag Sponsor: Onmidex

Omnidex is a British owned, single-source provider for a range of metal and plastic fabrication, casting, machining, finishing, assembly and other manufacturing services from concept to completion.

Driven by a passion for quality for more than 20 years, Omnidex has provided world-class engineering outsourcing services at a competitive price. Its experience and expertise spans almost all sectors, including aerospace, automotive, consumer products, medical, oil and gas, and more. With customers in the UK, the US, South Africa, Australia and many more, Omnidex is a global business.

Underpinned by its highly skilled engineers and supported by a vetted network of subcontractors and stringent quality control processes, the company invests regularly in the latest equipment and technologies to deliver cutting-edge, high-quality products and services to its customer base.

Omnidex

www.omnidexcn.com

Stand C141

Registration Sponsor: Turkish Machinery: The voice of Europe’s sixth largest machinery sector

Machinery Exporters’ Association (Turkish Machinery) represents and promotes the interests of its 18,000 members. It does so by coordinating and delivering sector-specific networking opportunities, business intelligence, and international events and trade missions.

The Turkish machinery sector has recorded robust growth over the past decade and has increased by more than 400% since 2003. It is now Turkey’s second largest exporter, worth some $25.5bn in 2022 – equivalent to 10% of total exports.

Centrally situated between Europe and Asia, Turkey is ideally located close to several of the highest-growth industrial machinery markets. Turkish machines operate in more than 200 countries around the world with a particularly strong presence in the US and Europe.

Buyers are drawn to the strong emphasis Turkish machine manufacturers place on R&D activities, the rapid adoption of international manufacturing standards and new technologies, a highly educated and skilled engineering workforce, and high-quality aftersales support.

Turkish machinery

www.turkishmachinery.org/En

Stand D121

EXHIBITOR PROFILES

With over 200 exhibitors and thousands of products and innovations on display, Subcon is a must-attend event for the engineering sector. Below is just a small sample of the world-class suppliers who are exhibiting at Subcon, all eager to help prospective customers optimise productivity and remain competitive in a global marketplace.

Citizen Machinery UK (stand A119) combines two leading manufacturers of CNC automatic lathes: Cincom sliding head lathes up to 38mm, and Miyano fixed headstock lathes from 36mm up to 80mm. The company offers highly productive and cost-effective solutions for complex metalcutting requirements.

Cornelius Electronics (stand A121) is a well-known and established subcontract manufacturer of box build, bespoke cable assemblies and wiring harnesses, serving a variety of industries. The business has the technology and expertise to deliver repeatable, quality-controlled and scalable production capacities to meet demand.

Bespoke aluminium extrusion supplier Edmo (stand A141) is committed to exceptional quality at every stage of a project. Its complete range of extrusion and machining services is complemented by its powder coating and assembly divisions, delivered by a global network of specialists, keeping prices competitive and lead times short.

For more than 40 years, Faro (stand E109) has been a global leader in 3D measurement, imaging and realisation solutions, bridging the digital and physical worlds through data-driven reliable accuracy and precision, enabling customers to make smarter decisions faster.

Its product portfolio includes portable CMMs, laser trackers and scanners plus a wide range of software solutions.

JKN Oil Tools (stand C119) is a precision engineering company based in West Yorkshire producing high-quality subcontract machined parts and fabrications to customers’ specifications and delivery requirements. It supplies components and fabrications to a large variety of customers, including major pump manufacturers, valve companies, food machine manufacturers and a wide range of smaller sectors.

Keyence (stand A99) has steadily grown since 1974 to become an innovative leader in the development and manufacturing of industrial automation and inspection equipment worldwide. Its products comprise code readers, laser markers, machine vision systems, measuring systems, microscopes, sensors, and static eliminators.

Founded in 1987 by Franco Stefani, Modula Storage Solutions’ (stand E128) mission is simple – to provide customers with effective storage solutions. Modula manufactures automated storage solutions offering one of the most advanced picking systems in the Vertical Life Module market.

The company is headquartered in Salvaterra di Reggio Emilia, Italy and Lewiston (ME) in the USA. Modula also distributes its services worldwide.

Oldham Engineering (stand C129) is an established sub-contract medium-to-heavy engineering business offering services that include precision CNC machining, fabrication, welding, robotic welding, mechanical assembly, equipment refurbishment, turnkey projects and project management. The company offers batch manufacturing as well as the capability to produce bespoke smaller quantities and one-offs.

For more than 35 years, Powdertech Surface Science (stand G120) has provided technically advanced powder coating and surface treatment services to the automotive, medical and specialist niche sectors. Projects benefit from its expertise built on years of experience in highly regulated industries, together with the scientific knowledge of its well-qualified team.

Shropshire Stainless and Aluminium (SSA) (stand G123) is a leading metals and plastics stockholder based in the UK and Ireland specialising in the supply and processing of aluminium and stainless steel from European suppliers.

Vector Blue Hub (stand F108) is a specialist electronics design and manufacturing services company based in Poland. It operates a ‘under one roof’ concept, where the design and manufacturing services remain in one place to accelerate the time to market for electronic products.

The extensive knowledge Vector Blue Hub has gained over the years in leading large-scale, comprehensive projects enables us to adjust our design and manufacturing services to meet your business challenges in industries such as Telecommunications, Industrial IoT and Communication Technologies.

EXHIBITOR PRODUCT HIGHLIGHTS

A trio of connector innovations from Harting

Harting is a leading expert in the fields of electrical, electronic and optical connection, transmission and networking. The company is renowned for developing innovations that provide simple yet reliable solutions, especially as markets and industries evolve quickly.

This ingenuity will be on full display at Subcon 2023, where Harting will be showcasing a range of new products. For example, when Han-Modular was released in 1993, it was the first modular industrial connector to run power, signal, and data alongside each other in a single connector. Now Harting has launched the next development stage, Han-Modular Domino modules, which meet the industry’s requirements for space and weight savings.

Using Han-Modular Domino modules can save up to 50% installation space by integrating different transmission types in one module. This results in the connection technology becoming smaller and more lightweight. Additionally, the new smaller modules require less energy and raw materials to produce. Domino modules are also compatible with existing components of the Han-Modular series.

Additionally, Harting also offers a new, complete cable assembly for energy storage systems. The new Han S connector range makes it easier to connect large arrays of battery storage modules, expanding the use of renewable energies such as wind and solar power.

To futureproof device technology, Harting has developed the ix Industrial, a compact interface that delivers excellent performance and robustness.

The ix Industrial interface needs 70% less installation space compared to typical RJ45 sockets, enabling manufacturers to use it in much smaller devices and more easily meet the needs of miniaturisation.

Despite its compact dimensions, the ix Industrial still produces Cat 6A performance for 1/10Gbit/s Ethernet at a control level, while its high current-carrying capacity supports both existing and future Power over Ethernet (PoE) applications.

Harting

www.harting.com

Stand D118

Treadstone Safety: safety without compromise

At its first-ever Subcon, Treadstone Safety will be presenting its Pro range of work safety gloves, including the:

PRO-420 with superb touch sensitivity: designed for optimal comfort and dexterity, these soft, touch sensitive and close-fitting ‘second skin’ gloves offer excellent grip in dry applications with a thumb crotch for added security

PRO-216 with touchscreen technology> made using graphene composite blended yarn, this glove is the ultimate in cut resistance. The glove has been dipped with a special nitrile foam to provide touchscreen capability on the palm, thumb and fingers. It also features a thumb crotch for added security

PRO-801 with impact protection: made with HPPE multi-threaded yarn for excellent cut resistance and a tough nitrile, sandy palm coating to cut level E. The glove features Treadstone’s TPR-1 impact system for enhanced protection against impact and crushing injuries

Treadstone Safety

www.treadstoneproducts.com

Stand D108

EXHIBITOR NEWS

Midtherm’s laser focus on growth after £1.2m machine investment

Midtherm Laser, a specialist subcontract laser cutting and forming specialist, is reaping the operational and environmental benefits from one of the largest purchases in its history.

The company, which employs almost 50 people at its West Midlands factory, has increased its capacity and processing speed thanks to the installation of a new Bystronic ByStar Fiber 12kW laser with part automation.

The machine will help the company deliver high cutting dynamics and thin-to-thick cutting capabilities to a customer base that spans aerospace and automotive to food and agriculture.

The investment has also made a significant difference to the firm’s environmental performance, with the Bystronic model replacing two older CO2 machines and delivering a 50% energy saving – the equivalent of powering 2,100 average homes every month.

Midtherm Laser works with more than 500 companies across 20 different sectors, cutting and forming various sheet metal from 0.5mm to 30mm. It also claims to be the only subcontract laser provider that offers the cutting of non-ferrous materials without the risk of cross-contamination for industries including food processing and chemical manufacture.

Midtherm Laser

https://midthermlaser.co.uk

Stand A89

UK-based rapid prototyping

DVR, a leading subcontract electronics manufacturing company, has introduced its new low-cost, fast-turnaround prototyping service to enable design engineers to rapidly evaluate new and innovative electronic concepts.

With a few simple clicks, its new prototyping service Speed Assembly Services (SAS) can deliver custom-made PCB assemblies in as little as 24 hours, depending on component availability and lead-time.

An online ordering tool empowers engineers to self-serve and control all aspects of the ordering process, all while having multiple customisation options and minimising quoting and ordering times.

SAS Ltd is the ideal supplier for low quantities, new product introductions, prototypes and concept PCBs. Learn more by visiting A129

DVR (Speed Assembly Services)

www.saspcb.co.uk

Stand A129

Escatec invests in new Innovation Hub to support growing demand

A rapidly expanding customer base with numerous high-tech projects has prompted integrated electronics manufacturing services (EMS) provider Escatec, to establish a dedicated Innovation Hub.

The facility, located 200m from its site in Switzerland, will provide Escatec’s design and development team with a creative workspace to meet customers and support them in turning their conceptual thoughts and early design ideas into market-leading products.

Established in 1974 with its headquarters in Penang, Malaysia, Escatec offers a fully integrated portfolio of electronics, electro-mechanical, and box build manufacturing services with a network of modern production facilities in Malaysia, the Czech Republic, the UK, and Switzerland.

Escatec

www.escatec.com

Stand E108

WEC Group: an all-encompassing manufacturing solution

WEC Group, one of the largest fabrication and subcontract engineering companies in the UK will be showcasing its subcontract manufacturing capabilities which include laser/waterjet/plasma cutting, small to large fabrication, CNC machining, sheet metalwork, CNC punching, polishing, shotblasting, powder coating and wet painting.

With around 900 members of staff spread across nine manufacturing sites in the UK, 25 lasers (including three tube lasers), 23 press brakes, 40+ CNC machines, three waterjet machines, two plasma cutters and over 200 highly skilled welders/fabricators, the company has one of the country’s most impressive contract manufacturing line-ups.

WEC Group is a key player in all the main industry sectors including nuclear, defence & security, aerospace, rail, construction, food processing, commercial vehicles and automotive.

It has been another year of strong growth for the group and the company has re-invested over £5 million across its various sites in additional machinery to increase capacity and reduce lead-times. New additions include a third fibre tube laser, a 12kW flatbed fibre laser, and various new machining centres including a fourth large floor-type machine capable of machining parts of up to 11.5m in length.

WEC Group’s marketing manager Jean-Yves Dziki, says: “We are very much looking forward to be back at Subcon again this year to meet with customers old and new. This will be WEC Group’s 10th attendance at the event and we are keen on promoting our new capabilities to all show visitors and discuss how we can add value to their supply chains.

“Our main USP is that we always strive to make our customers’ life easier by offering them a true full in-house manufacturing solution, which can help them drastically reduce their manufacturing costs and save them a few logistical and operational headaches along the way.”

WEC Group

www.wec-group.com

Stand B129