Taking tube sheet production to new levels

The acquisition of two state-of-the-art machine tools from TW Ward CNC Machinery (Ward CNC) has enabled Dukinfield-based TPG Engineering to create an advanced manufacturing centre specifically designed to machine large components made from exotic and hardened metals for the nuclear industry. PES reports.

The acquisition of two state-of-the-art machine tools from TW Ward CNC Machinery (Ward CNC) has enabled Dukinfield-based TPG Engineering to create an advanced manufacturing centre specifically designed to machine large components made from exotic and hardened metals for the nuclear industry. PES reports.

TPG Engineering, a specialist manufacturer of heat exchangers and condensers, has established an integrated, advanced manufacturing centre that will the company says will revolutionise tube sheet manufacturing on the site.

The company is a subsidiary of the TP Group – a major Tier 2 supplier to prime contractors in industrial, energy, process and defence sectors. The Group has invested almost £2 million in machines, facilities and personnel to build one of the most cutting-edge facilities of its kind in the North West of England.

The centre was initially designed for the production of high-specification heat exchanger tube plates, required for a major nuclear power project won in 2016. The company’s project director, Darren Sadler, comments: “The combined capability of these machines is ideal for the production of physically large and highly accurate workpieces. These are predominantly in titanium as well as other exotic/hardened materials, and with tolerances within 0.2mm, they are fit for nuclear engineering clients throughout the world.”

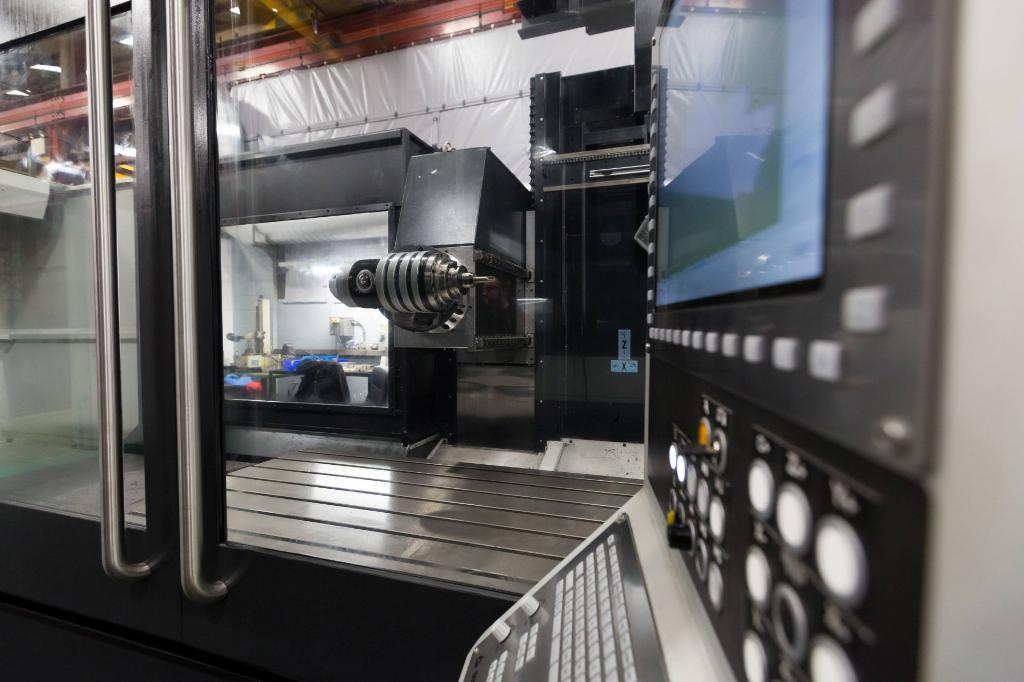

The company has installed a Soraluce TA-A35 travelling table mill-bore centre and a Hankook VTC 200 E vertical turning lathe (VTL) featuring extensive machining capacities. The Hankook VTL has a 2,500mm diameter table capable of accommodating workpieces of 2,000mm diameter and weighing 12,000kg; and the Soraluce mill-bore centre features 3,500mm x 1,250mm x 1,200mm in the X-, Y- and Z-axis travels for components weighing up to 7,800kg.

Mr Sadler continues: “Importantly, very few companies in supply chains outside of OEMs have a VTL of this size, so we are very well positioned as a supplier to handle such large components.”

He adds the 28kW Soraluce, with its 40-tool stations and 4,000rpm automatic indexing (in 2.5° increments) machining head represents an invaluable production asset. This is especially true when it comes to producing the PCD pattern of holes on exchanger plates, which can vary from 13mm to 16mm diameter.

In addition, the Hankook VTL’s specifications are highlighted as attributes that will set TPG Engineering apart.

Mr Sadler explains: “These include a torque rating of 40Nm, which is crucial when machining such high-grade materials, motors of 55kW (table), 22kW (for milling), 9kW (C-axis) and 7kW (for the X-Z axes servo), plus a 24-tool magazine, 12 each for turning and milling tools.”

The two machines were supplied to TPG Engineering by TW Ward CNC Machinery, the exclusive agent for these machines in the UK and Ireland. They are sited in a specially-created advanced manufacturing centre at TPG Engineering’s Greater Manchester base and, together with a large-capacity CMM that is enclosed in its own cleanroom, the machines represent an excellent facility for the manufacture of such parts.

Combined continual improvement

The machines are complemented by the company’s other manufacturing services, including fabrication and welding, as well as assembly, that are underpinned by continual improvements to existing manufacturing processes and systems.

Mr Sadler notes: “We are moving forward in two ways. We want to elevate existing work to new, higher levels due to the accuracies and tolerances achievable with these machines. Additionally, the machines’ expansive work envelopes will also enable us to accommodate additional, larger workpieces.”

With extensive experience in aerospace manufacturing, and aerospace design engineering, Mr Sadler joined the company with the remit to advance TPG Engineering into a new era of effectively and efficiently machining large and often complex workpieces in hard-to-machine materials, and to high levels of accuracy.

“TPG Engineering has an established history in the oil and gas industries and was ready to progress with existing customers and, crucially, become a major player in the nuclear sector for larger capacity machining,” he says.

Working closely with the Nuclear AMRC, where trials on similar components were held, the research centre effectively acted as advisors on machines best suited to the challenging requirements.

Beating bottlenecks

TPG presented the Nuclear AMRC with specifications for a series of typical parts which require vertical turning, milling and boring. For maximum flexibility and agility, and to avoid potential production bottlenecks, two separate machines were suggested – a VTL and a mill-bore centre.

The company soon found that Ward CNC could not only offer suitable machines, but that its back-up service, support and applications engineering input was also exemplary.

Mr Sadler says: “The new machines and the Nuclear AMRC have also introduced us to new lessons in tooling and machining methods; in some cases providing creative process solutions such as machining vertically rather than horizontally, to aid swarf removal.

“Also included here is the use of high-pressure (70 bar) coolant on both machines and the application of speeds and feeds that are different to the norm on certain components depending on material type and thickness. In addition, in some cases we’ll be drilling up to 14 x diameter rather than the traditional eight times, while still maintaining the desired accuracies. The new machines are encouraging us to look at the complete manufacturing process and effectively re-define how we manufacture tube sheets.”

First use of the machines is on the company’s new two-year £1.5 million contract with GE Oil & Gas. Mr Sadler explains that the aim of TPG Engineering’s advanced manufacturing centre is to differentiate itself by establishing a facility that enables even the most complex, heavyweight components be produced more quickly than ever to meet demanding safety and quality standards.

“These components will by their nature be processed in small batches, and we are uniquely positioned to be able to handle these in the most efficient way. Our investment in the advanced manufacturing centre effectively futureproofs what we are doing.”

TW Ward CNC Machinery (Ward CNC) www.wardcnc.com

TPG Engineering www.tpgroup.uk.com