Laser machine upgrade

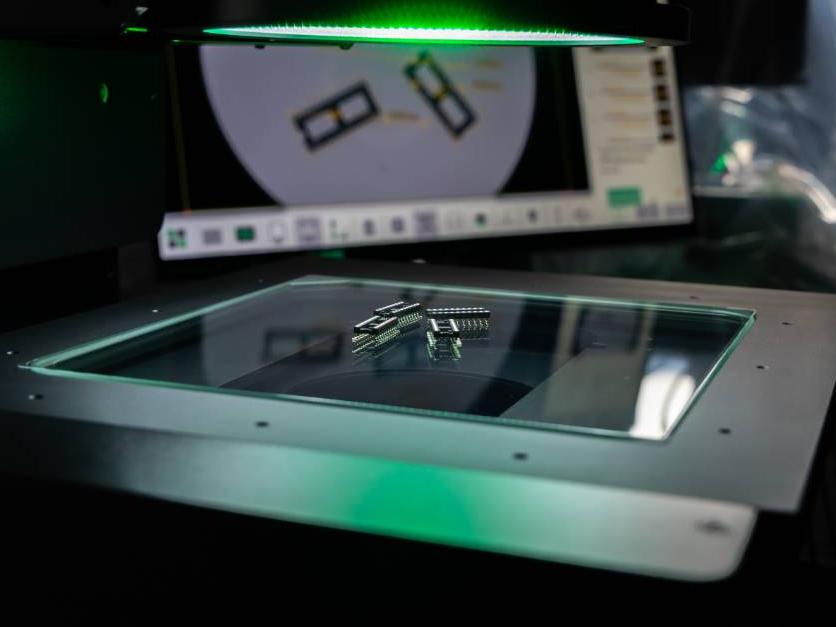

Spanish company TCI Cutting has upgraded its Smartline Fiber 3015, 2D laser cutting machine to bring even more value to customers seeking maximum flexibility and productivity in sheetmetal processing.

The compact footprint, Smartline Fiber 3015, which now offers 15kW of power and 19.6m/s² (2G) acceleration, is an ideal solution for companies with processes that require flexibility in production, both in parts, materials and thicknesses.

Good accessibility to the cutting table and 950kg maximum load capacity combined with user-friendly operation and reliability helps eliminate downtime and improve productivity. The Smartline Fiber 3015 offers high cutting quality across a variety of materials such as steel, stainless steel, aluminium, brass and copper in thin to medium thicknesses.

Included in the specification is a high precision cutting head, fume extraction system, automatic focal control, automatic nozzle cleaning, and an intuitive and easy-to-use HMI. The machine has been designed with optimum energy efficiency in mind.

It can also be optimised via various levels of intelligent automation for automated loading, unloading and storage which is complemented by the implementation of intelligent TCI Manager production management software.

TCI Cutting www.tcicutting.com