Thame Workholding: manufacturing in the UK since 1946

Aylesbury, Buckinghamshire-based Thame Workholding is understandably proud of its right to use the ‘Made in Britain’ Collective Mark, and justifiably so, because as a UK manufacturer of chuck jaws and workholding equipment it is something of a rare breed these days. Dave Tudor reports.

It's interesting how many engineering businesses have their respective roots in subcontracting. It’s something that I come across often and Thame Workholding is one such company. Its history reaches back to 1946 when, you guessed it, it began life as a subcontractor, offering its machining services to OEMs who presumably had no manufacturing capabilities of their own. Pretty much like it is today in many ways.

“That was certainly the case in the early days,” Thame Workholding managing director, Mark Thomas reflects. “But then one of the directors decided that we needed to develop products of our own to build a brand – and those products were chuck jaws. The TEC (Thame Engineering Company) brand was born along with the TEC Diamond mark that is used on every product we’ve ever made. Today the mark still represents British made products manufactured to the highest quality.”

Today, the manufacturing pedigree is as strong as ever spanning the design and manufacture of standard and bespoke chuck jaws, accessories, workholding equipment, manual rotary tables and fixtures in-house from its 12,000ft² facility in Long Crendon. Its routes to market are basically threefold: directly; through a tried and trusted distribution network; and via its recently launched online webshop.

complementary technology

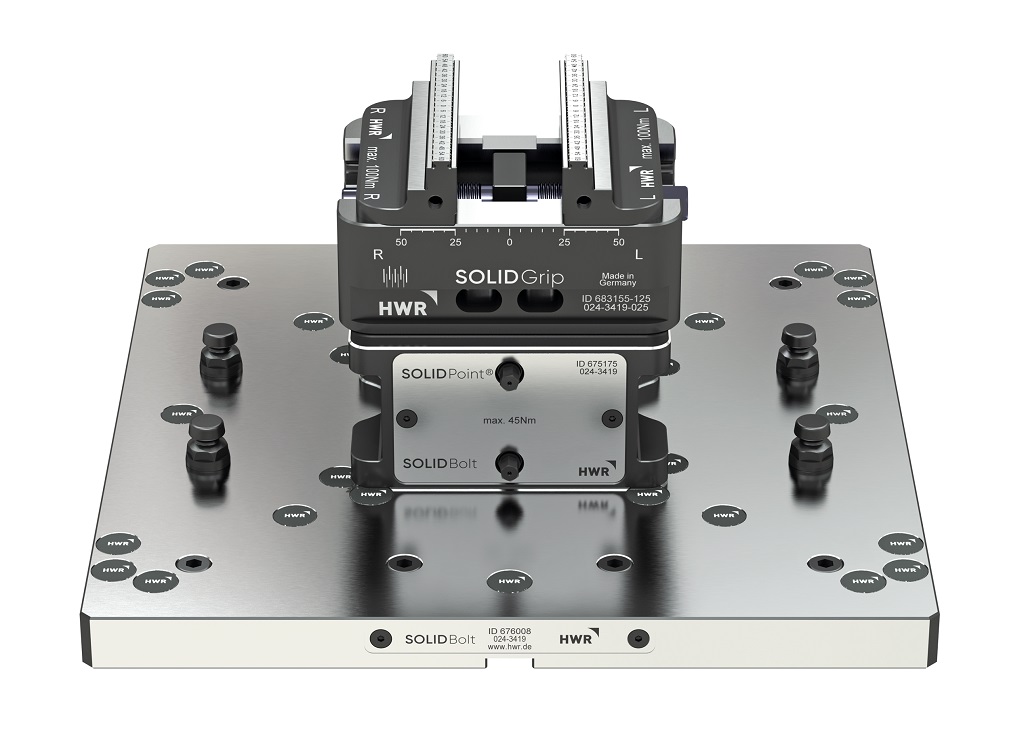

Thame also has exclusive distribution agreements with: German workholding specialist HWR Spanntechnik (SOLIDline and INOLine); Samchully in South Korea for power chucks, hydraulic cylinders, manual chucks, special chucks, vices and rotary tables; Witte Barkskamp vacuum workholding systems; and Rotor in Switzerland for revolving and dead centres and air chucks. The most recent distribution agreement is with Idaho-based Air Vise, a specialist manufacturer of fully controllable pneumatic mill vices.

A product Mr Thomas feels is worthy of note from HWR is its patented Inoflex chuck design which offers concentric, independent clamping flexibility on chucks up to an impressive 2m in diameter. Its compensating features means that it can clamp virtually any shape during turning and milling – round, cubic or geometrically irregular.

Whereas conventional chucks work with all jaws moving in the same direction either towards or away from the centre of the chuck, Inoflex operates with the jaws moving together or apart on two parallel axes. Compensation is provided to the diametrically connected base jaws by a sliding gate type gear mechanism.

Every cloud…

Mark Thomas is a relatively new recruit to Thame Workholding having held the position of managing director for just two and a half years. His co-partner in the business is manufacturing engineering director Mark Randall, a former Mazak applications engineer who had worked with previous Thame owners, husband and wife team David and Hilary Handley. It was Mr Randall that suggested they give Mr Thomas a call.

“I’ve always been inspired by British manufacturing and Mark knew that David and Hilary were looking for someone to ultimately take over the business,” Mr Thomas explains. “British manufacturing is something I’m 100% passionate about and I’ve actually walked away from businesses that have decide to shift their manufacturing operations overseas. It simply isn’t my ethos at all. Thame had established, longstanding, globally renowned products, designed and made in the UK and that ticked all the boxes for me.”

Rather than reinventing the wheel, Mr Thomas, once he was in the driving seat decided to focus the business on what it did best – designing and manufacturing a wide range of soft and hard chuck jaws comprising serrated, slot and tenon, T-nuts, scroll, multi-point rocker, quick change, base and monobloc variants.

To an onlooker, his timing in terms of taking over the company on face value couldn’t have been worse because it was in the middle of the COVID pandemic. However, it did buy the new owners time to evaluate the way forward; they looked at how to increase productivity and make production more efficient and cost-effective.

“The quieter period enabled us to build up really healthy levels of stock,” Mr Thomas affirms. “In the past, supplying products in short lead-times was a problem because we had no surplus stock. Now, I like to think of Thame as the ‘go to’ company for the rapid turnaround of chuck jaws.”

Established brand

Taking over any business always carries an element of risk – especially in the middle of a global pandemic – but for Mark Thomas, he believes it was the right decision. “Look, if I don’t get this right I’ll be living in a tent but I have no doubt in my mind,” he states. “We’re growing month on month and the things about this business that are worth their weight in gold are the 25 loyal, highly skilled members of staff we have and the fact that TEC is a brand people know and recognise.

“All TEC products that the company has ever made – certainly over the past 50 years – carry the Diamond mark – but they also carry a unique, indelible four or five digit product code that identifies that product family,” he adds.

“Customers call us for replacement jaws that we originally may have manufactured in the 1960s and 1970s. Because of the product code we can identify exactly what the jaws are and the chances are we’ll have stock so we can ship them next day either via a phone order or through our webshop. We actually stock nearly 1,000 different types of chuck jaws.

“We can only achieve these levels of service because our products have real heritage – and, because of the way we identify what we make, there’s full traceability. It will surprise some people that we have in excess of 1,000 customers with around 25% of our business serving an export market that spans the entire globe.”

Stocking strategies

Thame Workholding’s stocking capability follows a tried and trusted method where products are categorised. The bottom line is that it can supply most chuck jaws from stock and where this isn’t possible, it can manufacture on demand. In these times of interrupted supply chains, the business has also been forward thinking with raw material and has enough steel and aluminium in stock to meet current and future orders.

Category A products are the company’s bread and butter. These are standard, commonly used chuck jaws comprising around 100 lines. Generally there’s approximately 2.5 months’ worth of stock available for rapid delivery.

Category B products are not so readily available but Thame usually does have some limited stock to meet demand. If not, they can be manufactured within five to seven days. Finally we have Category C products which are those odd rarities. If you’re lucky, Thame may have a set or two in stock, but if not again they can be made from scratch albeit on a longer lead-time.

Customised solutions

Don’t forget Thame is also a specialist designer and manufacturer of bespoke chuck jaws, jigs, fixtures and associated workholding equipment. “In terms of volume, this type of work represents around 20% of the company’s overall business, but by value, because of the bespoke nature of the products, the figure is much higher,” Mr Thomas advises.

“It may be something of a cliché,” Mr Thomas adds, “but with our bespoke work we really are an end to end workholding solution provider. Sometimes the client provides a drawing but often we get involved with projects at the very beginning, working closely with the customer through design, prototyping and production.”

Of course each Thame product, bespoke or standard contains a unique product number so if future orders are required, the manufacturing records are readily available. Mr Thomas estimates that the company has access to around 50,000 unique products spanning decades.

Generally, bespoke jaws and workholding products are made to order for specialist customers operating in demanding industries such as medical (a particularly strong growth area for Thame), automotive, aerospace and oil and gas.

Complete control

It’s clear that one of Thame’s primary objectives is to keep as many processes as it can in-house and from a control perspective this makes sound business sense. Investing in new equipment is a strategy that dovetails well with this philosophy.

Thame’s most recent purchase was a Behringer automated saw for cutting raw materials prior to machining. Previously, this process was outsourced but now it can cut in three days what used to take three weeks. Future investment plan considerations include an EDM wire eroder and a large turning centre for machining adapter plates. About the only process that is still outsourced is heat treatment.

But the investment isn’t only about hardware. In April this year, complete with a comprehensive chuck jaw finder plus data searchable by product type, Thame launched its online webshop (https://shop.thameworkholding.com) which in essence was developed to replace traditional paper catalogues. If it’s in stock, product is shipped on a 24 hour delivery. Deliveries are also trackable.

“It’s early days for the webshop and while it won’t be the best route for more technical enquiries, on standard products it’s working well,” Mark Thomas concludes. “It’s a colossal job getting all TEC products plus those of our principals loaded up, but once it’s done I think it’ll really simplify and streamline the ordering process.”

Customers already receive a 10% list price discount when they buy online from the webshop, but PES readers can receive a further 5% price reduction by using the code PES05%.

Thame Workholding

www.thameworkholding.com