A need-to-have machine

The acquisition of a Mikron 5-axis milling machine from GF Machining Solutions is paying dividends for Huddersfield-based precision manufacturer Thomas Brown Engineering, where its performance and flexibility is proving crucial.

GF Machining Solutions, the EDM, milling and laser texturing machine tool manufacturer and automation and tooling systems specialist, has supplied leading precision subcontractor Thomas Brown Engineering with a new high-performance 5-axis machine.

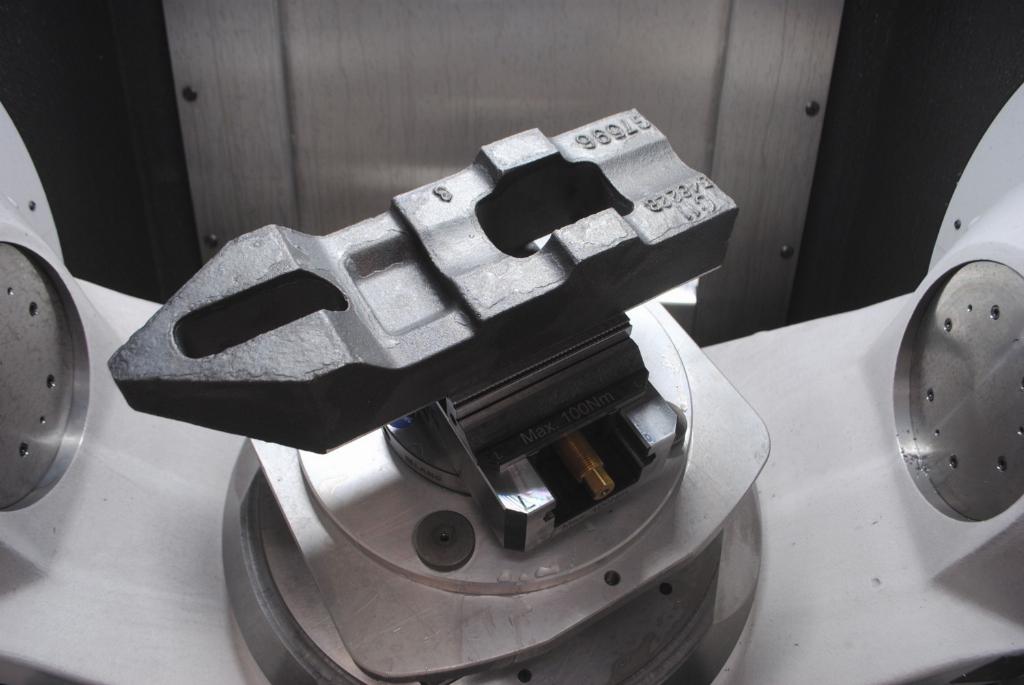

The Mikron Mill P 500U was installed at the company’s 20,000ft² facility in Huddersfield in January 2019 and is being used to machine precision components for customers operating in the aerospace, medical, automotive, robotics, food processing, oil and gas and steel manufacturing/processing sectors.

The components machined on the Mill P 500U are diverse and varied. Typical materials machined include aluminium, steel, stainless steel and Inconel, and batch volumes are mainly in the low to medium range.

The components machined on the Mikron are characterised by their accuracy and impressive surface finishes with a 20µm geometric tolerance and a Ra 0.2µm surface finish requirement being the rule rather than the exception.

“The sectors where we operate are competitive and demanding,” managing director Tom Brown begins. “Quality is non-negotiable and ever-stringent delivery times are increasingly prevalent. To meet customer demands and survive in these environments you need to be committed to continuous improvement and continually raise your game.

“By investing in the latest and most advanced machine tool technologies and by combining our manufacturing prowess with excellent customer service, we have found that we have been able to grow our business.”

Growth and change

Thomas Brown Engineering was established in 1983 the current owner. Over the last 35 years the company has grown steadily from being a one-man band to a business that now employs 20 members of staff. Other changes in the company have been even more noticeable – and dramatic.

“When the company was created it operated out of a couple of old garage units. Mr Brown continues. “As a fledgling engineering subcontractor, we were at that time, relying on a couple of used manual machines to machine parts and to make a living.”

Today, in stark contrast to these early days, the company has 14 CNC machine tools at its disposal and is looking to increase its floorspace (by the end of the year) by an extra 4,000ft².

The company's customer profile and customer base has also changed significantly.

“We are a Tier 2 supplier in the sectors where we operate,” Mr Brown explains. “The investment we have made in a plant, people, technologies, systems and processes has enabled us to consolidate our position in these sectors with existing customers, and also win new contracts and new customers.”

This is exemplified by the company’s position in aerospace sector where its AS 9100 accreditation has been instrumental in achieving a number of new contract wins.

This increase in demand for the company’s engineering services did, however, create some production issues resulting ultimately in the decision to invest in the new Mikron Mill P 500U.

“We audited and reviewed our machining strengths and weaknesses and identified where the pinch points existed,” Mr Brown comments. “The exercise helped determine that we needed to increase our 5-axis milling capacity and capabilities as a matter of some urgency.

“We had previously invested in a Mikron HPM 450U 5-axis machine some years earlier and the machine had served us well. We particularly liked the machine’s built-in automation and the way in which its integrated automatic pallet changers have helped us increase our productivity and efficiency and reduce our operational costs.”

Meeting the standards

The company drew up a list of technical and performance requirements for the new machine and benchmarked these against the 5-axis machines in GF Machining Solutions’ portfolio but it soon became clear that the Mill P 500U was the preferred choice.

The Mill P 500U is an ultra-high-performance, simultaneous 5-axis machining centre that offers powerful and dynamic material removal capabilities, thermal stability and high stiffness, to deliver excellent precision and surface finish on complex parts.

The machine features a thermo-stable and symmetrical design, so that even when machining at a fast pace and over long production runs, accuracy and process reliability remain high and consistent.

The machine delivers fast acceleration (1.7g) and is equipped with a formidable, high-torque 36kW Step-Tec motor spindle with fast acceleration. Productivity is enhanced by its in-built automation which comprises a 215 position ATC and possible 12 pallet APC.

Twists and turns

The company also wanted the machine to be able to perform interpolation turning operations. Interpolation turning is a machining technique developed for advanced machining centres and B-axis multi-task machines. It enables a turning operation to be carried out by interpolating the X- and Y-axis in a circular direction and rotating the machine spindle in time with the rotational contour.

The circular movement can either increase or decrease in diameter to produce facing operations or be combined with the Z-axis to produce a bore or outer diameter.

“The Mill P 500U is a great machine. It is accurate, fast and flexible. We mainly use the machine for 3+2 positional 5-axis machining operations as opposed to full simultaneous 5-axis machining and its performance to date, no matter what we’ve asked it to do, has been exceptional,” Mr Brown concludes.

Thomas Brown Engineering https://thomas-brown-engineering.co.uk

GF Machining Solutions www.gfms.com/uk