Time saving software

Tebis, the software and process provider for the development, design and manufacture of models, moulding tools and components, has made its version 4.0 release 3 available in the marketplace.

With this update of the CAD/CAM software, the company claims customers will be able to design their processes more efficiently. The newly added functions allow users more flexibility and cost-efficiency in design manufacturing preparation and processing, saving them considerable time. This is supported by more intuitive and simpler operation.

Toolbars and menu panels can be easily docked to the edge of the application window and the software interface is more informative for the user. A new project dialog with the most recently used files is displayed immediately after the program is started, so the user won’t lose any time after an interruption. This is supplemented by preview images of saved components.

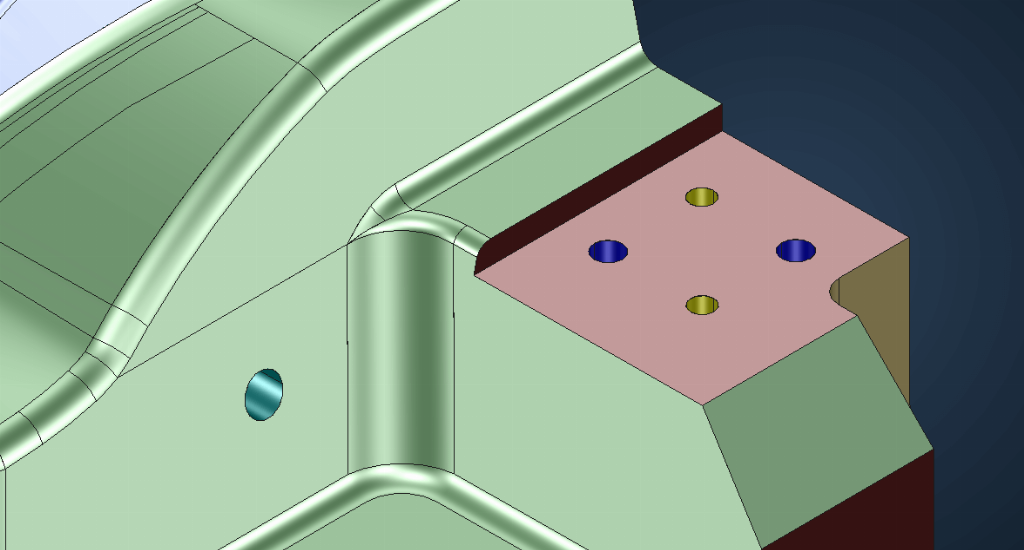

With Release 3, Tebis has also improved the display of wireframe models and isolines. With the latter, the user is often confronted with the problem of many isolines which can make the view of the components unclear on screen. The colours of the models can be adjusted independently of the surface colour in release 3.

In its update to Version 4.0, Tebis has focused on a more efficient use of time. Among other measures, the software achieves this by automatically breaking up assemblies and complex files with many manufactured parts into multiple individual files. The user can immediately access the corresponding component easily and conveniently.

Operators can also design active surfaces more quickly and spot them in try-outs. In addition, the software can very conveniently flatten positive radii which prevents any contact in the areas between the sheet metal and the die in the press. This is especially important for subsequent operations after drawing the component.

The customer can also save more time with optimised reverse engineering. Release 3 provides improved algorithms that generate perfect transitions for 4-edge surfaces. The user can also quickly and easily adjust the approximation tolerance as well as control generated radius runouts and theoretical edges more efficiently.

The software includes an automatic smoothing process for theoretical edges with few segments which saves the user valuable minutes when surface modelling. When generating surfaces with constant curvature, release 3 supports symmetrical areas for example, and provides better management of input parameters when using optimisation functions.

Additionally, version 4.0 delivers customers improved reliability in NC programs. An extended list with known machine conflicts is integrated in the CAD/CAM software for quick access which enables users to mark and filter acceptable and critical conflicts between the affected machine components. Release 3 provides an additional option for automatic collision avoidance in 3-axis milling.

The NC automation of 2.5D drilling and milling is also more efficient because the processing sequence in feature-based NC programming can now be more easily influenced by feature groups. Tool optimisation has also been extended in the Job Manager. Tools can be changed across machining operations in NC Jobs. The user can also assign NC variables across features. Standard and free-form functions can be selected independently of type and parameter assignment and the software always identifies currently different and modified variable assignments.

Also included is a function that is ideal for engraving texts, logos and numbers. The operator receives a text that is projected on the component geometry. A new function has been incorporated to calculate the 5-axis toolpath required for this operation.

The user can shorten cycle times by roughly 30% in laser cutting and trimming through improved NC point distribution resulting in more compact programs. Axial tolerances can be set and NC points manually removed.

In release 3, head tilt directions on the manufacturing machines can be handled easily in stamping areas which prevents rapid pivot movements of the machine. And toolpaths can be checked numerically with the collision check machine add-on, so that collisions and limit switch conflicts never even occur, saving more time and costs.

Tebis www.tebis.com/uk/en